Dedicated to optical metrology

Meeting the ever increasing demands of next generation optics

In depth asphero-diffractive analysis

- Easily analyse complex diffractives beyond 500 zones

- Identifies zone diameters with direct comparison to

design - Output diffractive form error for toolpath correction

Unique solution for rapid X-offset correction

- Significantly reduce SPDT setup time

- X-offset and form error can be corrected from a

single analysis - Improve throughput with time saving

Large diameter optics

- Class leading single trace measurement with lengths

up to 300 mm - Class leading straightness over full 300 mm length

- SAG > 28 mm

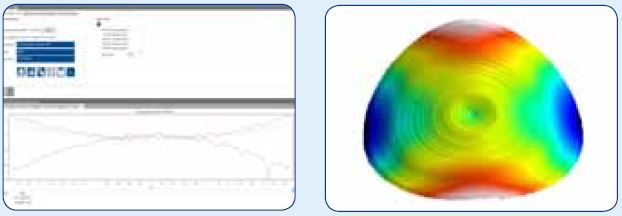

Astigmatic analysis

- Easy to program and use routines to determine if

astigmatism is present in parts - Output average profile for toolpath correction

- 3D residual surface generation for advanced

corrections

Aspheric optics are now specified for a wide variety of industrial, defence and consumer applications.

Taylor Hobson is the metrology provider of choice for aspherics manufacturers.

Single-Point Diamond Turning (SPDT) allows high precision aspheric optics to be manufactured quickly and efficiently. Sub-wavelength form accuracy specifications mean that metrology is critical to the manufacturing process. Taylor Hobson’s Form Talysurf PGI Aspherics Measurement System sets the global standard for optics users, delivering form accuracies as low as 1/10 Angstrom.

Diffractive Optics

Diffractive Optics with Aspheric base forms are typically manufactured using Single Point Diamond Turning. In order to control this process so that sub-micron form accuracies can be achieved, Taylor Hobson’s Form Talysurf is an essential metrology tool.

Diffractive lenses and mirrors have a number of critical dimensional features, which determine the component’s optical performance. These include underlying aspheric form, zone height & diameter, and surface finish.

Taylor Hobson have many years experience of meeting the measurement requirements of this highly specialist application.