Ball Screw Axial Measurement Machine

Ball screws are routinely used for a wide range of applications. These include aircraft control surfaces, landing gear, precision machine tools, automotive steering, and numerous other applications. In this Application Note, we consider the challenges involved in measuring Ball Screws, outline the limitations of traditional methodology methods and detail the solutions provided by the Form Talysurf® PGI NOVUS system and Metrology 4.0 software for ball screws axial measurement machine.

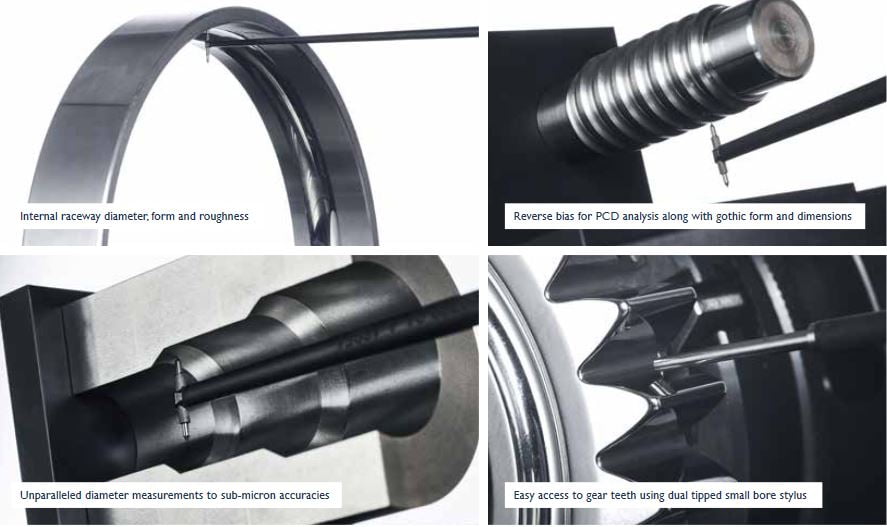

Rapid Roller Bearing Measurement

Taylor Hobson roller bearings measurement/checking instrument for bearing manufacturers. There are a wide variety of roller bearings available that serve a diverse range of applications. Tapered, cylindrical, and needle roller bearings are just a few of the types available. Roller bearing elements require good surface finish, form, and precise dimensions to provide low noise and high load capacity in the roller bearing assembly.

How to Measure 2D X Auto Roller Bearings

Taylor Hobson roller bearings measurement tool for bearings manufacturers. The ‘2D X Auto’ feature in Metrology 4.0 software. It simplifies the measurement of roller bearings by precisely auto-detecting the edge at the start and end of the roller and it provides the analysis of roughness, wall thickness, dimension, and waviness, etc. It is no longer necessary to set the traverse length! This is a huge benefit as, typically, most manufacturers will have many different sizes of roller bearing to measure. The ‘2D X Auto’ feature provides measurements from and to edges, saves time, and helps protect the stylus from potential damage.

Angular Contact Bearings measurement

The PGI Novus surface profilometer provides full, rapid measurement of Angular Contact Bearing inner and outer races. It determines the precise location of the raceway profiles and their centers relative to the bearing reference faces. The analysis includes radius, roughness, form, angles, and other critical dimensions. Exceptional diametral and dimensional accuracy is assured by the use of the PGI Novus Dual Bias Gauge. Precise positioning of the stylus tip on the bearing is made possible by Taylor Hobson’s unique ‘SMART Move’ capability and Part Co-ordinate System. The whole process is fully automatic and provides a powerful analysis of critical features, along with toleranced results in a format easily configured to suit your requirements.

Production interface – Pallet of parts measurement

This video shows how to use Form Talysurf PGI NOVUS to measure multi parts. Any site or combination of sites can be selected. Parts can be the same or completely different. All the measurement progress is updated live on the product interface. Results can be viewed individually, or view multiple results side by side. Toleranced results are tabulated with clear PASS/FAIL indication.

Measure Multiple Parts & Features Using Single Program

Using Taylor Hobson’s Metrology 4.0 software with variables, multiple parts, and multiple features can be measured using a single program, significantly reducing the amount of time and effort required to write and maintain measurement programs.