MTL are optical measuring machines designed to measure turned and ground pieces, like camshafts, directly in the shop-floor because, these machines, are equipped with double temperature compensation system on diameters and on lengths. MTL are not, in fact, a simple measuring instrument but the best assistant that the operator may have. Can carry out measurements directly on site instead of in a standard room, keeps CNC centers in production by removing machine downtime for setting or production changeover phase by reducing measuring time of the first piece produced and prevent discarded items before values are out of tolerance. These machines has a wider front opening that helps loading / unloading procedures. During this phases, the measurement sensors reach a rest position, sheltered from front or lateral impact. MTL software allows operators to work on the real image of the piece so we can quickly measure diameters (static, dynamic,interrupted, etc.), lengths, angles, radii, geometric measurements (parallelisms and orthogonality), shape measurements (circularity, coaxialities, run-outs,cylindricities) and DXF comparison.

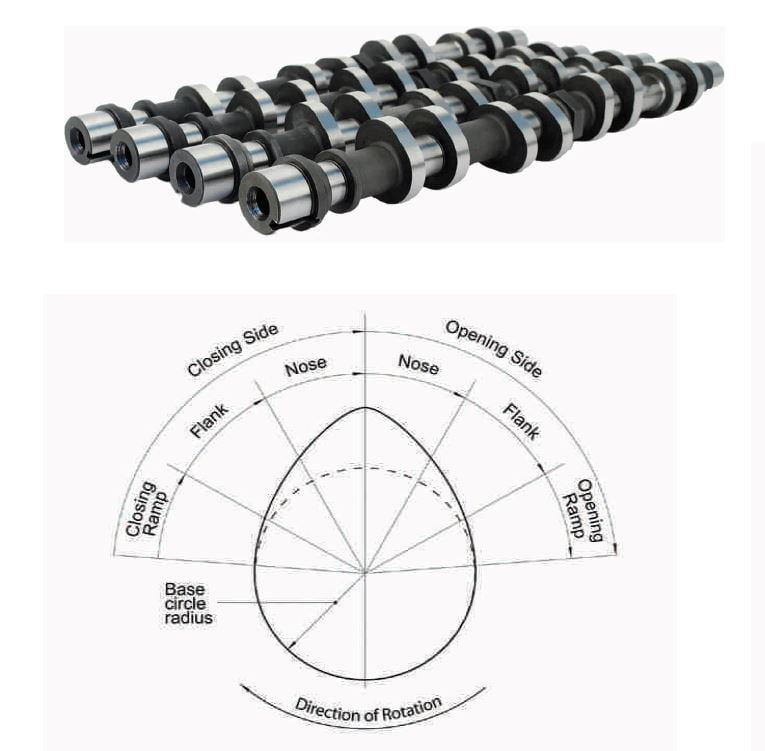

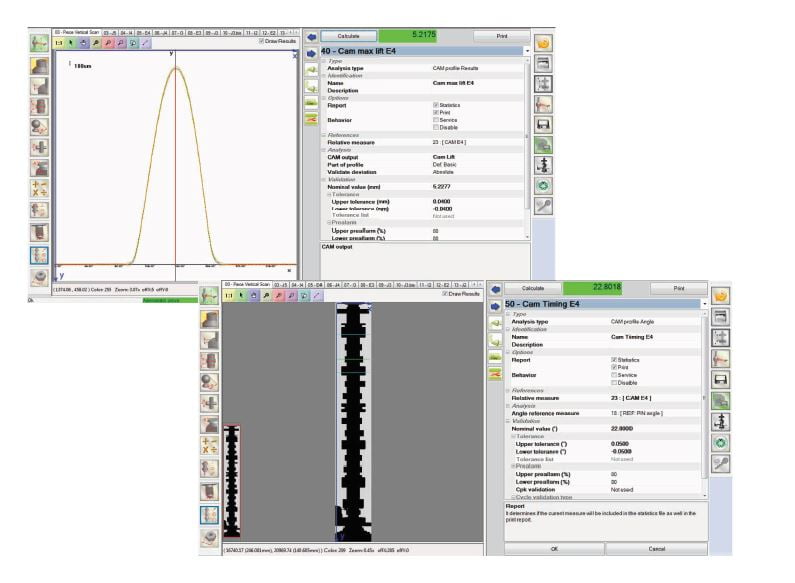

A special camshafts tool helps to measure a wide range of particular. Just insert theoretical data like cam basic radius, tappet type, law of motion and we receive:

- The basic radius validation

- The maximum cam lift

- The deviation of the computed law of motion from theoretical

- The deviation of the velocity

- The deviation of the acceleration

- The basic profile run-out