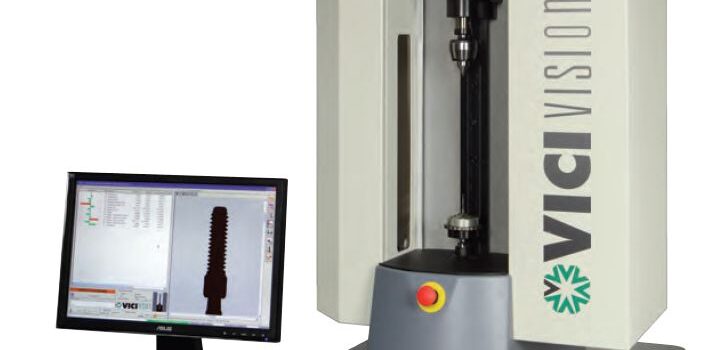

Vicivision is the optical measuring machine specific for components of micro mechanical systems: for the dental sector, the biomedical and watches, screws for eyeglasses and other elements extremely minutes because it allows you to check the external profile also details extremely small thanks to its measuring range of 16×100 mm detected by advanced optics with pixel 4×4 microns.

The machine performs the measure on the real image of the workpiece strongly enlarged in order to obtain measures of lengths, diameters, angles, radii, bevels, threads even for the smallest details without the uncertainty of manual measurements and with the advantage of automatic control , extremely fast, accurate and objective.

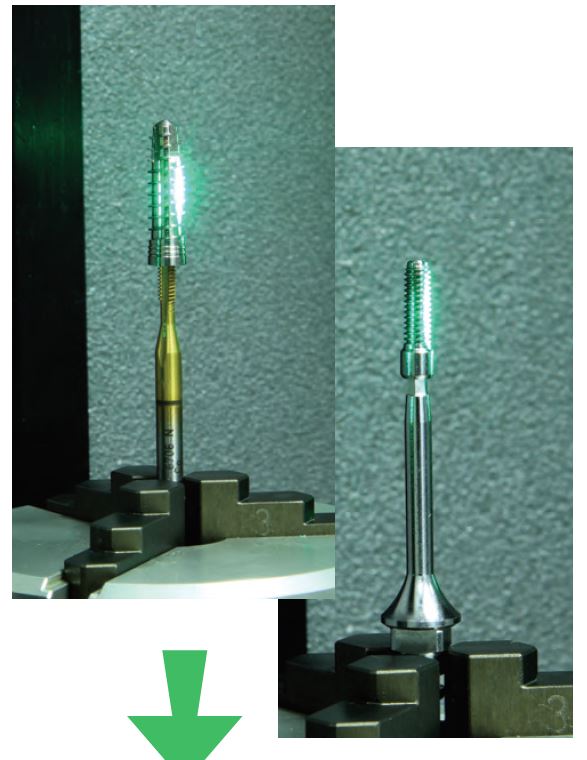

Through a system of rotation of the workpiece, moreover, allows the measurement of defects in the form.

With Vicivision each operator is able to control the production, without the need for specific skills of measurement.

It is sufficient, in fact, perform the measurement program with a simple click and in a few seconds one obtains an outcome detailed and clear component under test.

All the data obtained are collected by the system and output statistical and traceable result, in order to obtain measurement reports and monitor the trend of the production.

It is distinguished for the extreme efficiency in measuring complex components such as implants straight and tapered, pillars, abutments, extenders, exhaust hoods, cover screws, attacks to ball and pins in titanium.