Coordinate Measuring systems

Showing 19–27 of 28 results

-

Coordinate measuring machines

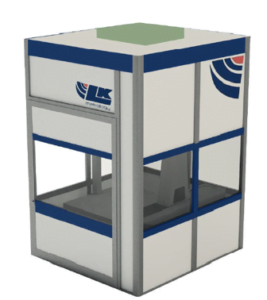

LK MAXIMA / MAXIMA R Coordinate measuring machine

LK MAXIMA / MAXIMA R Coordinate measuring machine

The LK Metrology Maxima, large bridge CMM range, is based on the same proven design concepts of the high accuracy LK Metrology CMM product portfolio.

The Maxima range offers three machine variants with a standard work-table version, a twin runway design, namely the R version and as a single raised shoulder version for easier loading and unloading of very long mechanical components. All variants are based upon a common modular design concept providing high performance, reliability and an easy to maintain measuring system.

(0 reviews) -

Coordinate measuring machines

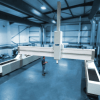

LK ULTRA Coordinate measuring machine

LK ULTRA Coordinate measuring machine

Made for very-large-scale measurement applications the LK Metrology Ultra CMM Series, with its elevated guideways design, offers among the best and most flexible solutions in the industry today for 3D dimensional inspection.

The Ultra range offers three machine design variants, the monolithic design with an integrated work-table, the classic gantry design, and the proven guideways on U-foundation design which can be implemented as above ground, ground level, or, in sub-ground foundation pit installations. All variants are based upon a common modular design concept providing high performance, reliability and an easy to maintain measuring system.

(0 reviews) -

Coordinate measuring machines

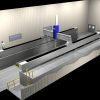

LK HD90 Coordinate measuring machine

LK HD90 Coordinate measuring machine

HD-90 is a heavy-duty ultra reliable high-performance CMM for deployment in production and shop-floor environments, developed specifically for car-body and sub-assembly quality control applications.

HD-90’s Runway design is specifically developed for single or double arm configurations. It is totally encapsulated in protective covers to ensure thermal insulation against environmental changes while protecting the system from the contaminants typically found in a workshop environment.

The open structure can be installed floor level or on the floor, the walkable guideways protect the X slideways and the completely encapsulated structure guarantee maximum accessibility in safety to the measurement area while simplifying manual or automated part loading and unloading operations, as well as allowing a safe utilization directly in any production area.

(0 reviews) -

Coordinate measuring machines

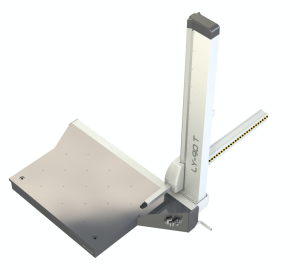

LK LY-90T Coordinate measuring machine

LK LY-90T Coordinate measuring machine

The LY-90T Console Design Series sports the horizontal arm installed on guideways side-mounted unto the granite or cast-iron plate allowing for measurement of small, medium and large sheet-metal and plastic components.

With the integration of a rotary table, cubic and complex geometry parts from various industries can also be inspected.

(0 reviews) -

Coordinate measuring machines

LK LY-90R Coordinate measuring machine

LK LY-90R Coordinate measuring machine

The LY-90R Series offers a technically advanced and cost-effective solution for the dimensional control of large components typical of the automotive, land transport and heavy industries.

LY-90R is equipped with air bearings both on the Y-axis and on the Z-axis which guarantee high performance and accuracy results. The X-axis guideway can be mounted on the floor or at floor level.

Heavy-duty walkable guideways provide safety for the operators and the system in a shop-floor environment. The open structure allows for the inspection of large heavy parts, placed on a work-plate, fixture or automated loading-unloading system.

(0 reviews) -

Accesories

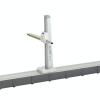

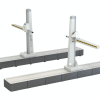

CMM Checking Gauge (CCG)

CMM Checking Gauge (CCG)

The CMM Checking Gauge (CCG) gives confidence in the accuracy of your CMM, by enabling independent verification of accuracy using regular intermediate checks.

Quality control relies on measuring systems providing consistently accurate results. Regular checking of CMM performance provides an early warning of changes in system accuracy. Once identified, accuracy issues can be addressed before they impact downstream processes.

(0 reviews) -

-

Accesories

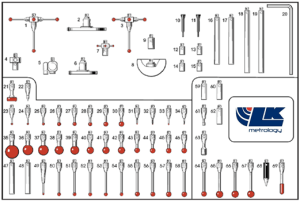

Stylicleaner LK

Stylicleaner LK

During measurement, and particularly when scanning, contaminants such as remnants of coolant, dust, oil and oxides build-up on the stylus of your CMM.

These tiny debris particles must be removed to continue to achieve high performance and accuracy standards. Manual cleaning is time consuming, often requiring re-calibration of the probe angles before use. That’s why with the Stylicleaner kit you’ll be able to automatically clean your CMM’s slylus in just 30 seconds.

(0 reviews) -