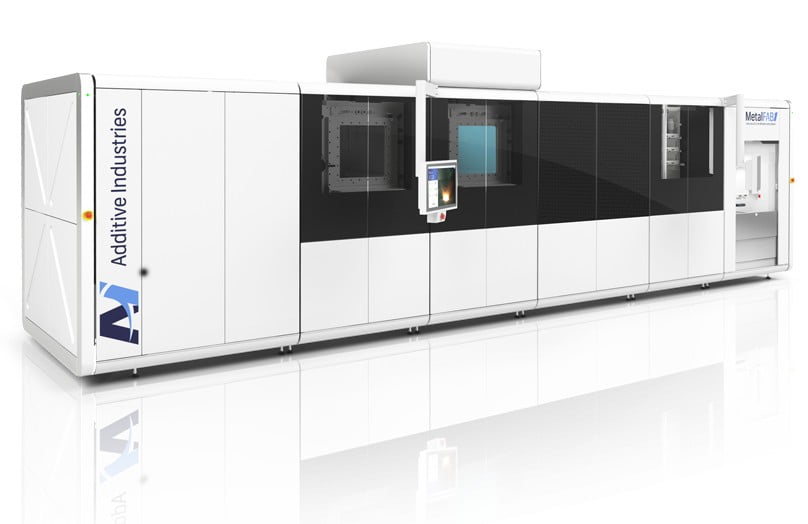

3D Metal printer - Additive Industries MetalFAB1

Integrated industrial additive manufacturing equipment

MetalFAB1 is the first integrated metal additive manufacturing machine. The MetalFAB1 uses powder bed fusion with multiple lasers. In addition to the core 3D print process, heat treatment, automated build plate handling and storage are also integrated into one industrial grade production system.

Born from high-tech heritage

MetalFAB1 was developed by a team of highly experienced engineers with a background in 3D printing complemented with high-tech equipment developers of semiconductor, electron microscopy and medical scanning systems. Open innovation has led to a new and distinctive system architecture based on well-proven concepts and efficient application of functional building blocks from robotics, lithography and other opto-mechatronical systems.

Built on predictable and reproducible processing

For industrial series production with additive manufacturing technology, reproducibility of the core 3D printing process is assured by a solid machine design in combination with a smart calibration strategy. Predictability is achieved by combining simulation and in-process quality controls with the core additive manufacturing process.

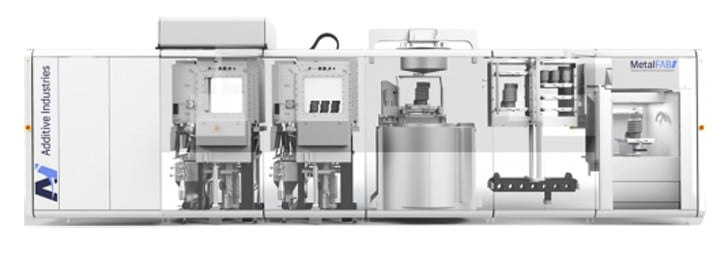

Maximum flexibility created by modular design

MetalFAB1 has a modular architecture. This allows the user to start with a basic machine configuration with the option to enlarge the scope of the process enabling increased productivity. Moreover, modules can be added to allow the use of multiple materials in one machine without having to clean the powder system and running the risk of cross-contamination.

Optimised productivity through integration

Additive Industries strongly believes in an integrated process flow for industrial additive manufacturing. Multiple process steps are combined in single machine using automated handling to reduce manual labour, improve product consistency and quality as well as increasing operator safety. A robot connects all process steps and allows for fully automated handling of both new build plates and ready products.