Working in shopfloor enviroments for more than 15 years. All the experience of thousands of VICIVISION customers in a machine optimised for turning process control.

High resolution

Detailed images capture even minute features.

Vicivision Techno series Optical Measuring Machines

Working in shopfloor enviroments for more than 15 years. All the experience of thousands of VICIVISION customers in a machine optimised for turning process control.

High resolution

Detailed images capture even minute features.

Keeping production in tolerance

Reduction in machine downtime thanks to immediate inspection without the need to leave the wokstation.

Significant reduction in rejects, implementing the preventive actions indicated by the measurement trend graphs.

Designed for everyday use

The real part image displayed by the software, combined with the large work area, gives a clear view of the condition of the part to be measured. Retractable sensors during loading and unloading provide more space in the work area for even greater convenience, easier access to the workpiece. The ergonomic workpiece clamping lever has a considerable width that allows both left- and right-handers to lock/unlock the workpiece without obstructing the view.

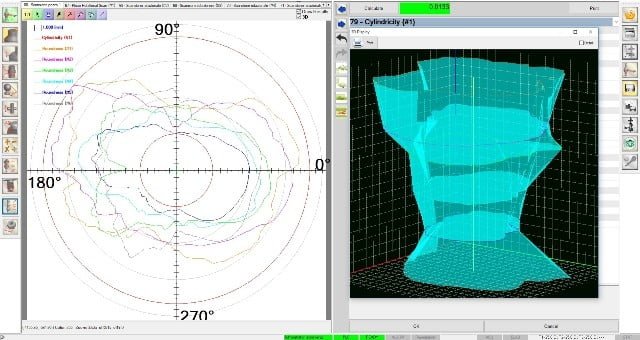

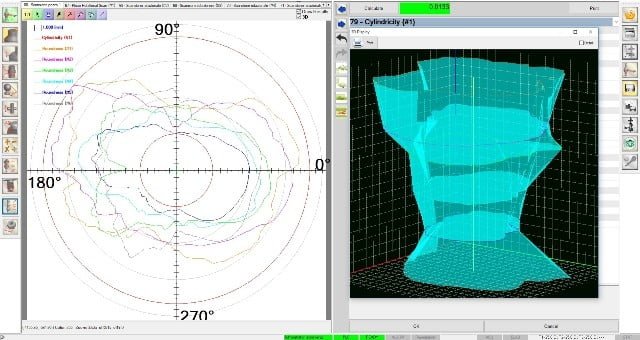

The MTL Techno series includes the functions of profile projectors, micrometers, roundness, eliminating human error in obtaining measurements and allowing operators to manage the acquired data.

Software with advanced features

Types of parts that can be analyzed

– Fittings – Fluid connectors – Spindle type parts

– Multi-axis parts – Pins – Precision screws – Rolled screws – Nuts

– Screws and bolts – Castings

– Castings for electrical components

– Pinion shafts – Valves – Valves – Hydraulic pistons

– Valves – Pneumatic cylinders – Turned parts

– Tooth implants – Transmission shafts – Gears – Screws

– Medical screws – Turbines – Turbo compressors – Camshafts

– Clock parts

– Injectors – Crankshafts – Car axles.

Download the brochure

Vicivision Techno series Optical Measuring Machines

Working in shopfloor enviroments for more than 15 years. All the experience of thousands of VICIVISION customers in a machine optimised for turning process control.

High resolution

Detailed images capture even minute features.

Keeping production in tolerance

Reduction in machine downtime thanks to immediate inspection without the need to leave the wokstation.

Significant reduction in rejects, implementing the preventive actions indicated by the measurement trend graphs.

Designed for everyday use

The real part image displayed by the software, combined with the large work area, gives a clear view of the condition of the part to be measured. Retractable sensors during loading and unloading provide more space in the work area for even greater convenience, easier access to the workpiece. The ergonomic workpiece clamping lever has a considerable width that allows both left- and right-handers to lock/unlock the workpiece without obstructing the view.

The MTL Techno series includes the functions of profile projectors, micrometers, roundness, eliminating human error in obtaining measurements and allowing operators to manage the acquired data.

Software with advanced features

Types of parts that can be analyzed

– Fittings – Fluid connectors – Spindle type parts

– Multi-axis parts – Pins – Precision screws – Rolled screws – Nuts

– Screws and bolts – Castings

– Castings for electrical components

– Pinion shafts – Valves – Valves – Hydraulic pistons

– Valves – Pneumatic cylinders – Turned parts

– Tooth implants – Transmission shafts – Gears – Screws

– Medical screws – Turbines – Turbo compressors – Camshafts

– Clock parts

– Injectors – Crankshafts – Car axles.

Financing solutions for the purchase of new equipment, through BCR Leasing or Grenke.

See Financing Methods| Model M304 | Layout- Layout 2/A Measuring field – 300 x 40 mm Max. loadable sizes – 300 x 120 mm – 10Kg Accuracy – 1+D[(mm)/200)] / μm 3+L[(mm)/200)] μm Repeatability – 0.3 μm / 1.2 μm Size LxDxH mm – 595 x 780 x 950 mm |

|---|---|

| Model M318 | Layout- Layout 3/E Measuring field – 300 x 180 mm Max. loadable sizes – 300 x 240 mm – 30Kg Accuracy – 1+D[(mm)/200)] / μm 3+L[(mm)/200)] μm Repeatability – 0.3 μm / 1.2 μm Size LxDxH mm – 920 x 1030 x 1800 mm |

| Model M604 | Layout- Layout 2/B Measuring field – 600 x 40 mm Max. loadable sizes – 625 x 120 mm – 30Kg Accuracy – 1+D[(mm)/200)] / μm 3+L[(mm)/200)] μm Repeatability – 0.3 μm / 1.2 μm Size LxDxH mm– 595 x 780 x 1315 mm |

| Model M618 | Layout- Layout 3/F Measuring field – 600 x 180 mm Max. loadable sizes – 625 x 240 mm – 30Kg Accuracy – 1+D[(mm)/200)] / μm 3+L[(mm)/200)] μm Repeatability – 0.3 μm / 1.2 μm Size LxDxH mm – 920 x 1030 x 2000 mm |

| Model M906 | Layout- Layout 2/C Measuring field – 900 x 60 mm Max. loadable sizes – 925 x 120 mm – 30Kg Accuracy – 1+D[(mm)/200)] / μm 3+L[(mm)/200)] μm Repeatability – 0.3 μm / 1.2 μm Size LxDxH mm – 595 x 780 x 2000 mm |

| Model M918 | Layout- Layout 3/F Measuring field – 900 x 180 mm Max. loadable sizes – 925 x 240 mm – 60Kg Accuracy – 1+D[(mm)/200)] / μm 3+L[(mm)/200)] μm Repeatability – 0.3 μm / 1.2 μm Size LxDxH mm – 920 x 1030 x 2000 mm |

| Model M2018 | Layout- Layout 3/H Measuring field – 2000 x 180 mm Max. loadable sizes – 2000 x 240 mm – 60Kg Accuracy – 1,5+D[(mm)/200)] / μm 4+L[(mm)/200)] μm Repeatability – 4 μm / 3 μm Size LxDxH mm – 920 x 1030 x 2770 mm. |