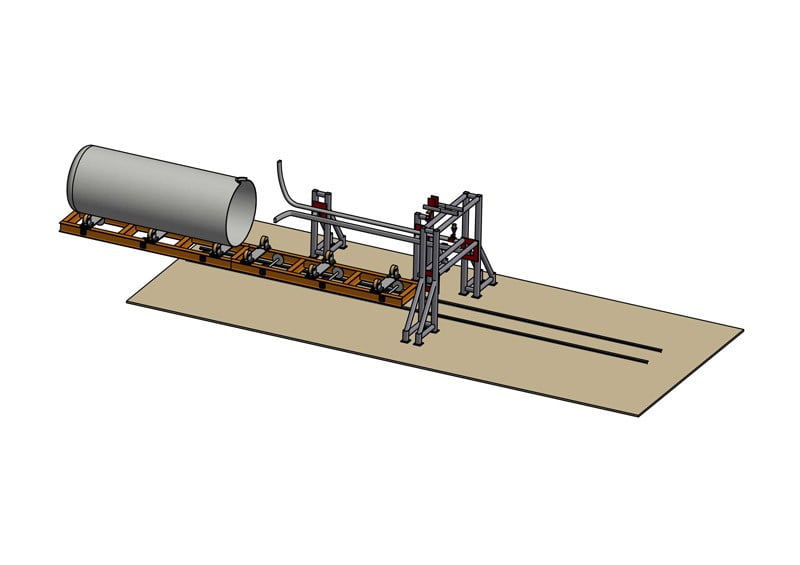

FlyAir Series laser source

The Unico and Flyair Compact systems are solid state laser for marking characterized by the generation of the laser beam within the cavity. The active material is YVO4 (yettrium orthovanadate neodymium-doped) with axial pumping diodes. The laser module is completely sealed, assembled and pre-aligned in the Clean Room. The two models – Unico e Flyair Compact are the same laser source: what differentiates them is the structure and the placement of the components inside. Unico has been developed as a single unit. This provides the smallest footprint, but optimal scanning over the widest area with easy and quick integration. The FlyAir Compact system, instead, is designed in two bodies connected through a steel cordon: a drawer that contains the management electronics and a group of components including the laser source and the scanning unit. In situations when the weight of the laser must be considered, this design offers an ideal solution by minimizing the overall weight. Both systems provide increased stability. Furthermore, the design of the diode connected directly to the cavity prevents any risk in rupturing the transport fiber. The air cooling is to ensure a constant temperature, and the diode is mounted on a Peltier cell. This type of laser is ideal for personalization type marking in which you can provide shades of gray – such as ID cards and marking of plastics.

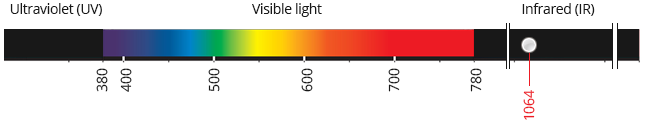

The IR wavelength which is an abbreviation for Infrared Ray is the most versatile wavelength of light for laser processing.

As the name implies, IR is the spectrums outside of red, which are invisible to human eyes (i.e. longer than 780 nm).

Typical characteristics of 1064 nm wavelength range lasers

• A wide range of processing applications from resins to metals

• Cannot process transparent objects like glass as the laser passes through such objects.

• Creates contrast on resins easily.

Download the brochure