Talyrond 450 - Taylor Hobson

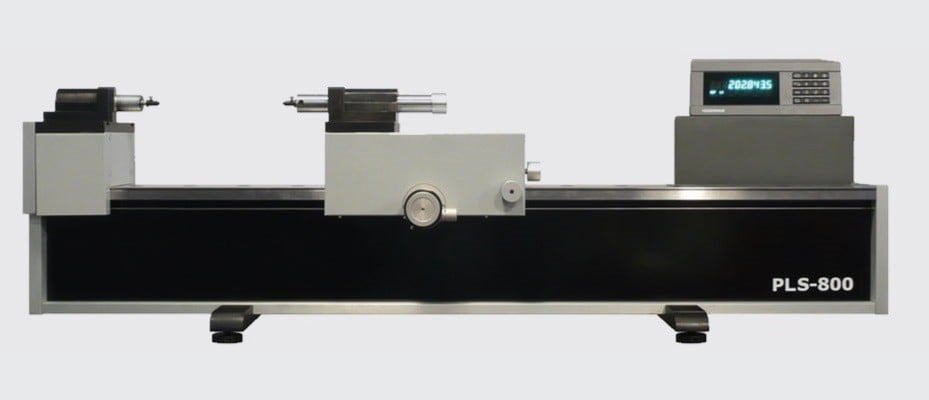

Talyrond 450 Roundness & Cylindricity Measurement Tester for Prismatic or Non Rotationally Symmetric Components

The solid cast iron base frame and column surround ensure stability during measurement while the high precision spindle and vertical straightness unit ensure repeatable and reliable measurement of roundness, cylindricity and straightness.

A high load capacity X,Y table with fully automated centre and level ensures precise set up and repeatability between operators. The entire system is completely automated utilising Taylor Hobson’s Ultra software, this software has many features ensuring measurement and analysis to national and international standards.

- Fully Automated Centre and level capability

- 1000 kg load X,Y table with high accuracy position control

- High accuracy spindle with large load capacity for special deep bore drop arms

- Straightness, parallelism and cylindricity measurement up to 1.5 metres

- Column heights of up to 2000 mm

- Windows based Ultra software with measurement traceable to national and international standards