Form Talysurf® PGI NOVUS - Taylor Hobson

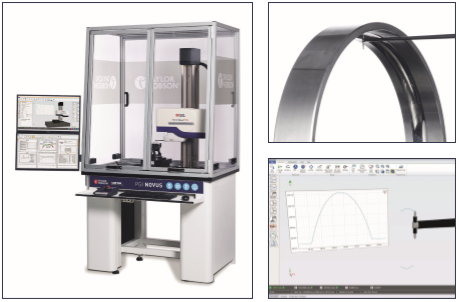

The New Form Talysurf®

The New Original.

Introducing, the most advanced system for surface finish, contour, 3D and diameter measurement.

At the heart of the new Form Talysurf® PGI NOVUS is a ground-breaking dual bias gauge. The NOVUS gauge provides the ability to measure diameter, included angle, surface finish in a normal and inverted direction with the same speed and accuracy. Through this development, Taylor Hobson has addressed challenges faced day-to-day by bearings, injectors and precision component manufacturers.

Unique benefits for both design and production.

One measurement, multiple results, instant feedback.

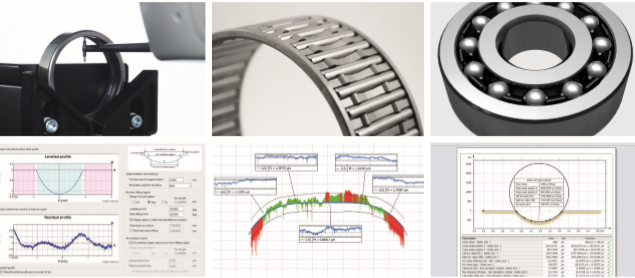

Surface finish – High resolution gauges with low noise enable roughness, waviness and form in one measurement.

Contour – Our patented calibration technique enables measurement of radii, angle, height, length, distance and more.

Topography – Using an optional motorized Y-stage and Metrology 4.0 software, transform your conventional 2D measurements into 3D.

Industry 4.0 – Smart Factories.

The future of modern manufacturing.

Industry 4.0 philosophy is driving what has been called a ‘Smart Factory’ through the process of automation, data exchange and control in manufacturing environments. A “Smart Factory“ includes a variety of modern technologies such as, Internet of Things, Internet of People, Cloud computing, Smart sensors and Advanced SPC software.

Taylor Hobson’s ongoing developments support this approach and are in line with the Industry 4.0 philosophy.

The Form Talysurf® PGI NOVUS delivers class-leading:

• Angle

• Diameter

• Radius

• Form

• Range

• Resolution