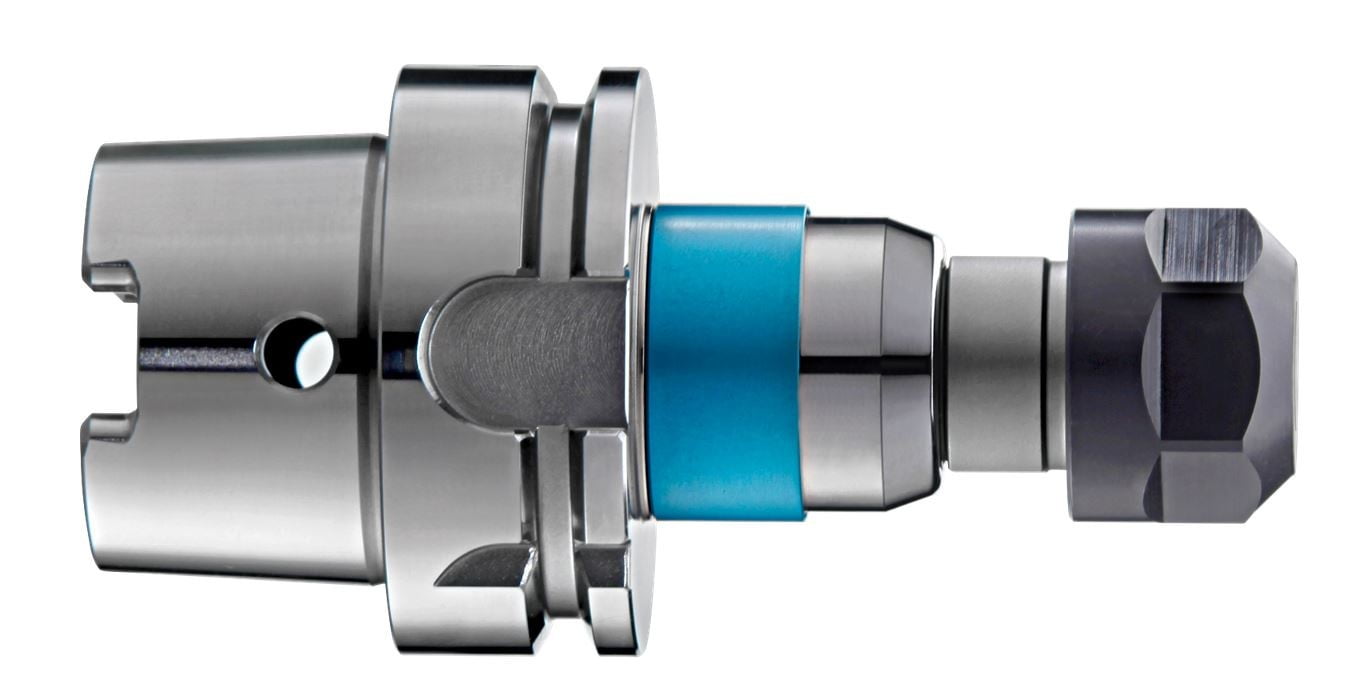

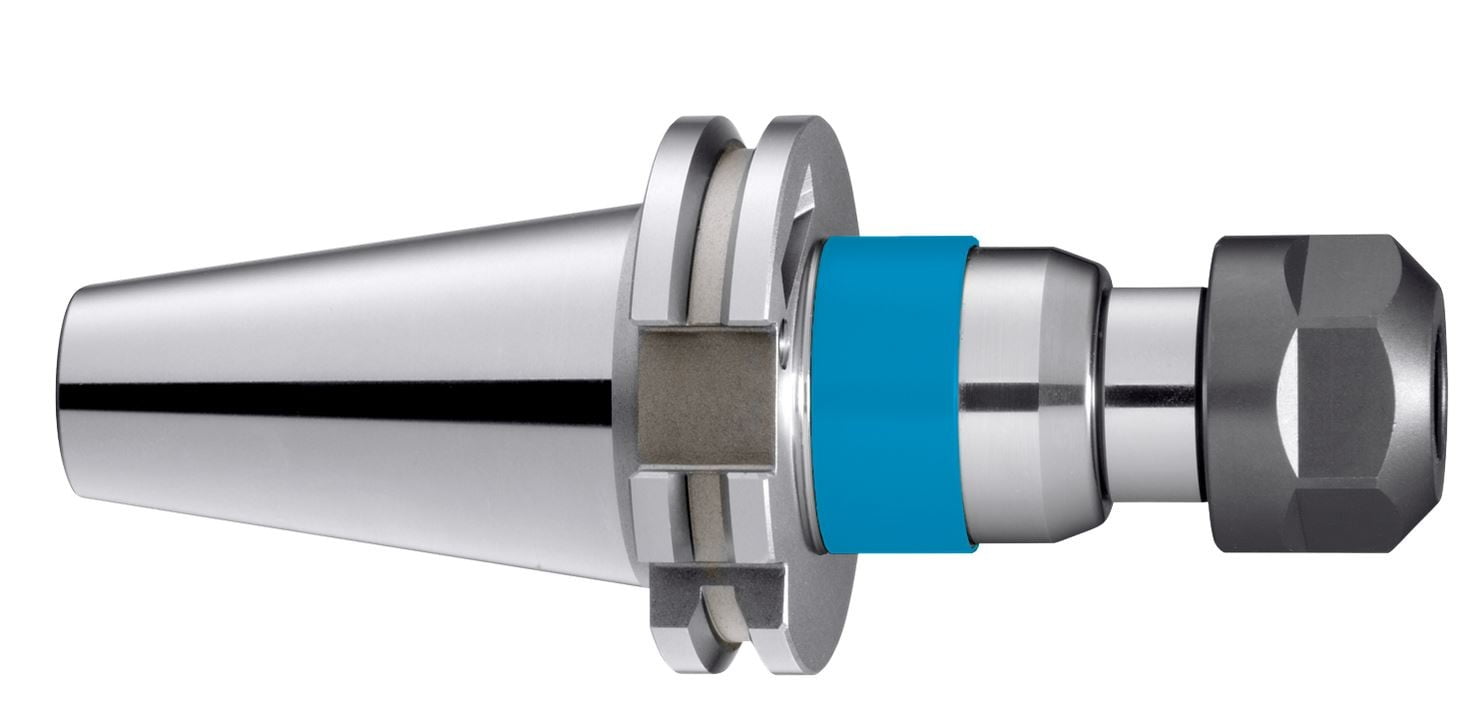

Bilz Synchro Tapping Chuck SCK

Application

Application: tapping, roll forming on machines with synchronized feed ( speed/feed synchronisation, also named Rigid Tapping)

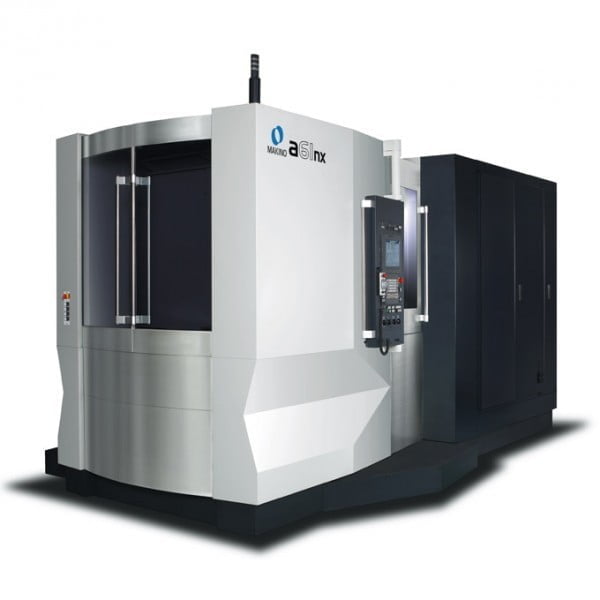

Machine type: machining centres, CNC-turning and special purpose machines with synchronized feed

for the tapping operation

Features

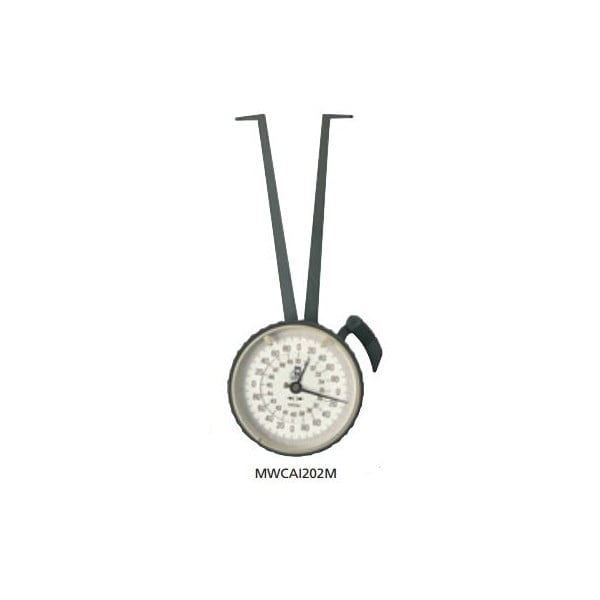

- minimum compensation on tension/compression

- compact construction

- dimensionally stable and very resistant elastomere

- minimal length compensation (pressure/retraction +/- 0,15 mm)

Advantages

- reduction of the pressure on the thread flanks – higher life time of the taps, less number of tools required

- compensation of the synchronisation error, while reversing the spindle – reduced risk of tool breakage – better thread quality

Description / Qualities

Market demands have triggered the development of the new design BILZ synchro chucks. Adjustment of the chuck with regard to the taps pre-setting position can be completed from both sides of the chuck, the minimum quantity lubrication has been optimised and comes with an absolute leak free application of lubrication flow to the tap. The tension and compression length compensation, (e. g. +/- 0,15 mm) in combination with radial dampening effect compensates small synchronisation and location anomalies. Through this defined application compensation the user achieves reduced tap flank wear in combination with considerably less cutting loads which in turn increases tap life and is more machine friendly.

The use of the “Elastomere” dampening and length compensating elements are form-secure, they are also resistant to all coolant substances used in today’s modern industries. Dampening elements remain stable due to the predetermined length compensation thus eliminating any potential plastic deformation. This results in a constant cutting condition and therefore the user benefits.

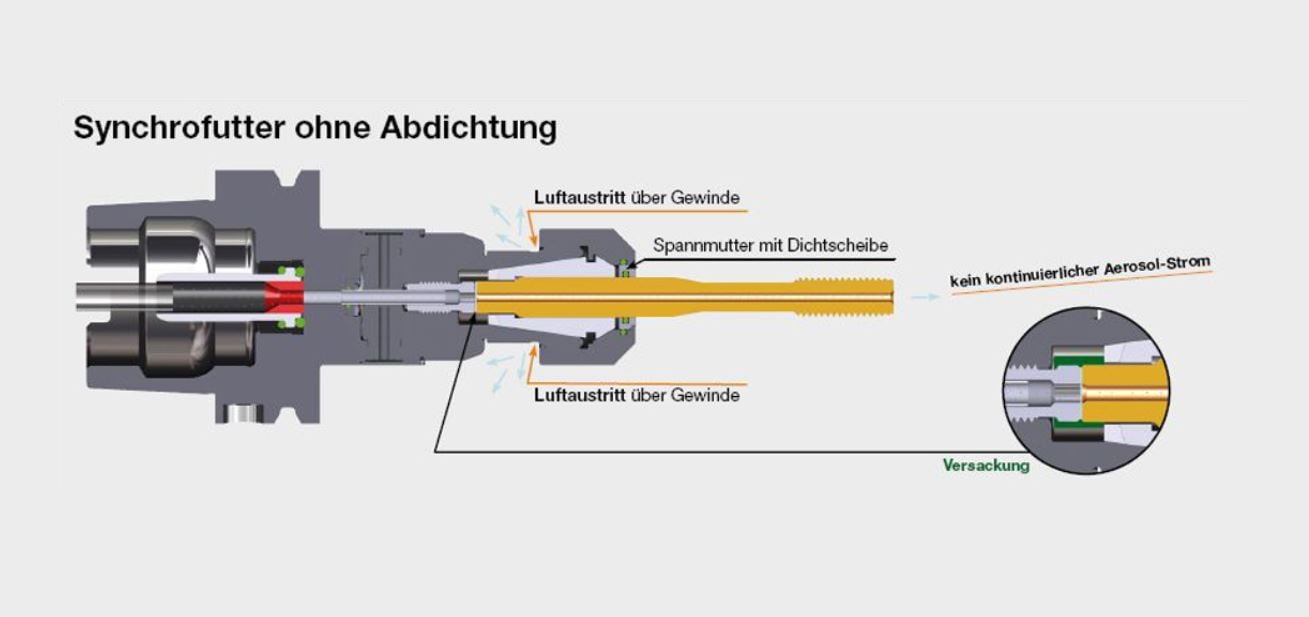

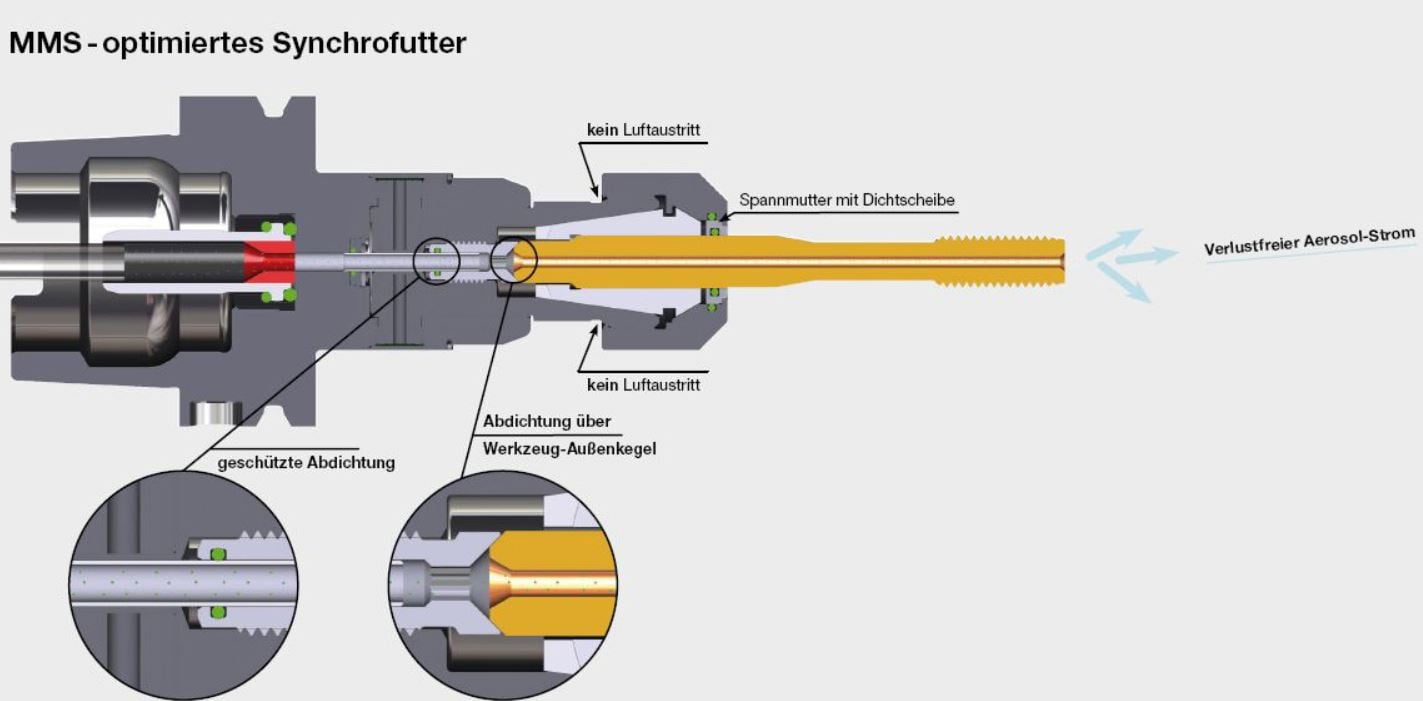

Success story SCK – unique feature 100% leak proof for MQL

Technical partnership as a guarantee for success

The new synchro chuck generation was developed in close cooperation with VW and the specialists of LMT – from the analysis of the problem and the development of an adequate solution up to the successful trials at VW:

The optimised SCK and the clamping chuck used up to that point were clamped onto a double-spindle machining centre in direct comparison to one another. Components made of AlSi9 were machined using a thread former from LMT-Fette at 6 bar pressure and maximum cutting speeds.

Whereas a fine mist of aerosol droplets forms around the old chuck, the optimised SCK runs flawlessly. No mist, no moisture in the tool shank. The aerosol exits 100% where it should – at the tool!