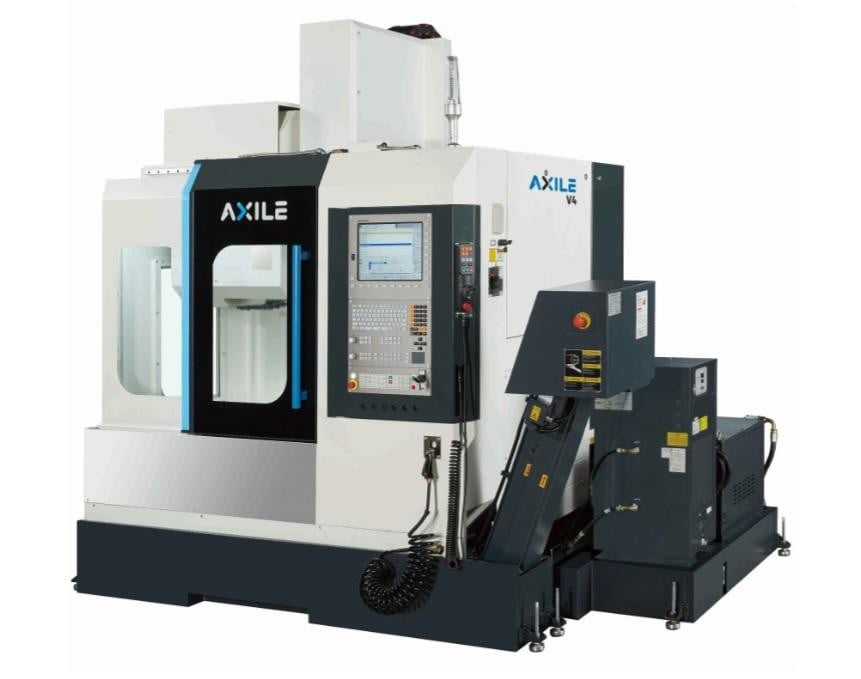

Centre de prelucrare verticale 3 axe - AXILE seria V

The V series high-speed machining center provides Die / Mold solution for high precise machining capability is realized by high spindle speed, fast acceleration/deceleration, and precision contour feed control. Machine frame is analyzed with FEM system to ensure the optimum machine stability. V combines the maximum productivity with reasonable investment.

Specification:

| ITEM | UNIT | V4 | V5 | V6 | V7 |

| Table size | mm | 700X410 | 900X520 | 1,200X600 | 1,400X710 |

| Max. table load | kg | 250 | 600 | 800 | 1000 |

| X axis travel | mm | 600 | 800 | 1000 | 1200 |

| Y axis travel | mm | 400 | 500 | 600 | 730 |

| Z axis travel | mm | 450 | 500 | 600 | 650 |

| Spindle speed | rpm | 12000 | 12000 | 12000 | 12000 |

| Motor output | kW | 10 | 10 | 20 | 20 |

| Max. rapid feed X/Y/Z | m/min | 36 | 40 | 40 | 40 |

| Linear guideway | Ball type | Roller type | |||

| ATC capacity | Tool | 30 | 30 | 30 | 30 |

| Accuracy ( x/y/z axes) | |||||

| Positioning | mm | 0.005 | 0.005 | 0.005 | 0.005 |

| Repeatability | mm | 0.005 | 0.005 | 0.005 | 0.005 |

Standard accessories:

| 4th axis preparation | |

| Spindle oil cooler | |

| CTS – 20 BAR built in type | |

| Chip conveyor | |

| 4 bar wash down device | |

| Grease lubrication | |

| Linear scales on three axes | |

| Tool-tip Positioning Control (TPC) | |

| Spindle Vibration Supervision (SVS) | |

| Axial Accuracy Control (AAC) |

Optional accessories:

| 18K spindle 170mm (E-Spindle) Extra (V4/V5) | |

| 24K spindle 170mm (E-Spindle) Extra (V4/V5) | |

| 15K spindle 210mm (Kessler) (V6/V7) | |

| 20K spindle 210mm (Kessler) (V6/V7) |