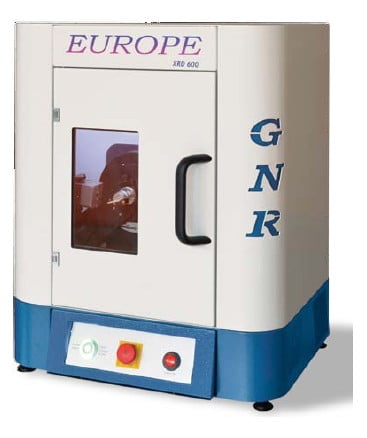

Difractometru X-Ray – GNR Europe 600

X-Ray Diffraction (XRD) is a non-destructive technique for the qualitative and quantitative analysis of the crystalline materials, in form of powder or solid.

GNR has developed, in cooperation with academic and industrial users, a set of technically advanced and flexible diffractometers able to satisfy different level of requirements and different operating budget.

GNR XRD Product Portfolio covers a huge range of applications for materials characterization and quality control of crystalline or non-crystalline materials such as powders, specimens, thin films or liquids.

How XRD works …

Basically XRD is obtained as the „reflection“ of an X-ray beam from a family of parallel and equally spaced atomic planes, following the Bragg’s law: when a monochromatic X-ray beam with wavelength l is incident on lattice planes with an angle q, diffraction occurs if the path of rays reflected by successive planes (with distance d) is a multiple of the wavelength.

Qualitative analysis (phase analysis) can be done thanks to the comparison of the diffractogram obtained from the specimen with a huge number of patterns included in the official databases. Single phases and/or mixtures of phases can be analysed with the programs available today.

When XRD could be used …

Many Investigations can be performed with the help of X-ray diffraction.

Residual Stress Forces that results in a small compression or dilatation of the d-spacing. With XRD it is possible to measure the strain (the deformation of the original lattice) and the stress is calculated thanks to the knowledge of the elastic constants of the material

Texture It is the preferred orientation of the crystallites in a specimen. If a texture in a material is present, the intensity of a diffraction line changes with the orientation of the sample respect to the incident beam.

Crystallite size and micro strain These information are obtained by the analysis of the width and the shape of the diffraction lines.

Structure analysis XRD is used to investigate the crystallographic structure of a material. The position and the relative intensities of the diffraction lines can be correlated to the position of the atoms in the unit cell, and its dimensions. Indexing, structure refinement and simulation can be obtained with specific computer programs.

Thin film Keeping the incident beam at low angles, it is possible to investigate the properties of multilayers, minimising the interference of the substrate. On the same way, reflectometry can be performed.

Europe 600 is a benchtop – Theta/2Theta – general purpose diffractometer for XRD qualitative and quantitative analysis of polycrystalline materials.

Its compact size and robust design enables installation and operations in a small space and low cost of ownership and maintenance.

Thanks to the wide offer of configurations and accessories, such as high speed detector, scintillation counter, secondary monochromator, spinner and multiple sample holder, Europe 600 is the perfect instrument for fast-paced routine industrial quality assurance analysis and for teaching XRD at academic level.

Europe operating at 600 watts enables faster analysis and oustanding overall results.

- Ultra Compact

- Theta/2Theta oustanding goniometer

- Fail Safe Radiation Enclosure

- Fast Detector available

- Incident Beam Variable Slit

- Simple Installation and Easy of Use

Applications:

Qualitative and quantitative phase analysis, non-ambient analysis, retained austenite quantification, structure solution and refinement, crystallite size and crystallinity calculations.

- Geology and Mineralogy / Clays

- Glass / Ceramics / Cement

- Chemicals / Petrochemicals

- Catalyst / Polymers

- Forensics

- Agricultural Sciences

- Biosciences / Environmental

- Pharmaceuticals

- Cosmetics

- Art and Archeology

Technical Data:

| X Ray Generator | Maximum Output Power | 600 W (option: 300 W) |

| Output Stability | ≤25ppm/hr after a 2 hour warm up | |

| Max Output Voltage | 40 kV (option: 30 kV) | |

| Max Output Current | 15 mA (option: 10 mA) | |

| Voltage Step Width | 0.1 kV | |

| Current Step Width | 0.1 mA | |

| Ripple | ≤1%rms at >20 kHz, 0.1%rms below 20 kHz | |

| Preheat and Ramp | Automatic preheat and ramp control circuit | |

| Input Voltage | 230 Vac +/-10%, 50 or 60 Hz, single phase | |

| X-Ray Tube | Type | Glass (option: Ceramic), Cu Anode, Fine Focus (options: any kind of X-Ray tube) |

| Focus | 0.4 x 8 mm LFF (other options available) | |

| Max Output | 600 kW | |

| Goniometer | Configurations | Vertical Theta/2Theta geometry |

| Measuring circle diameters | 150 mm | |

| Vertical Scanning Angular Range | – 5° < 2 Theta < + 145° (according to accessories) | |

| Smallest selectable stepsize | 0.005° | |

| Angular reproducibility | +/- 0.001° | |

| Accuracy | +/- 0.01 | |

| Modes of operation | Continuous scan, step scan, theta or 2 theta scan, fast scan | |

| Variable Divergence slits | 0 – 4° | |

| Variable Anti-Divergence slits | 0 – 4° | |

| Variable Receiver slits | 0 – 4° | |

| Soller slits | 2.3° | |

| Detector | Type | Scintillation counter Nal (options: YAP(Ce); multistrip) |

| Count rate | 10(5) cps (Nal); 2 x 10(7) cps (Yap(Ce)) | |

| Case | Dimensions | Width 600 mm, heigh 750 mm, depth 500 mm |

| Weight | 130 kg | |

| Leakage X-rays | < 1 mSv/Year (full safety shielding according to the international guidelines) | |

| Processing Unit | Computer Type | Personal Computer, the latest version |

| Items controlled | X-ray generator, goniometer, sample holder, detector | |

| Basic Data Processing |

Polynomial least squares smoothing. Fourier smoothing. Search for Peaks (automatic and manual). Spline background subtraction. Single peak analysis (area, FWHM, centroid, background). Marquardt fit (with pseudo-Voigt and Pearson VII curves, Ka2 contribution, weighted sum of squares). Sum and multiply by a constant. Scale normalization. Zoom. Graphical windows. Overlap and comparison of diffractograms. Multiview function. Cursor scan. Creation of graphic files .BMP. ICDD-PDF2 Card Overlap. Creation of calibration curves. Analysis of unknown samples. Qualitative and quantitative phase analysis. Rietveld analysis, crystalline structural analysis, crystallite size and lattice strain, crystallinity calculation |