Industria auto - solutii de marcare cu laser

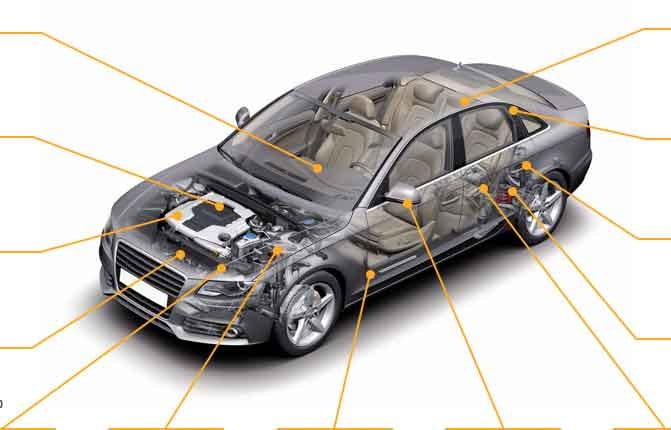

Traceable laser for every field

The ideal solution for all necessary marking, reading and verification

Flexibility

Everything. Everywhere. Wherever.

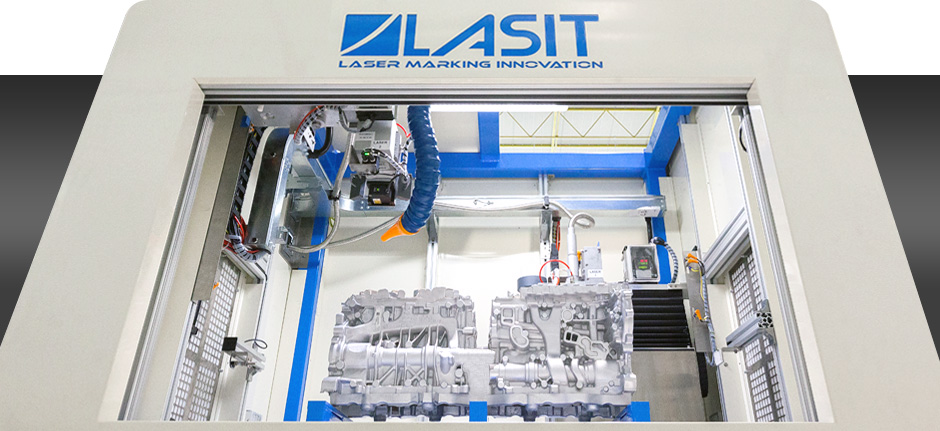

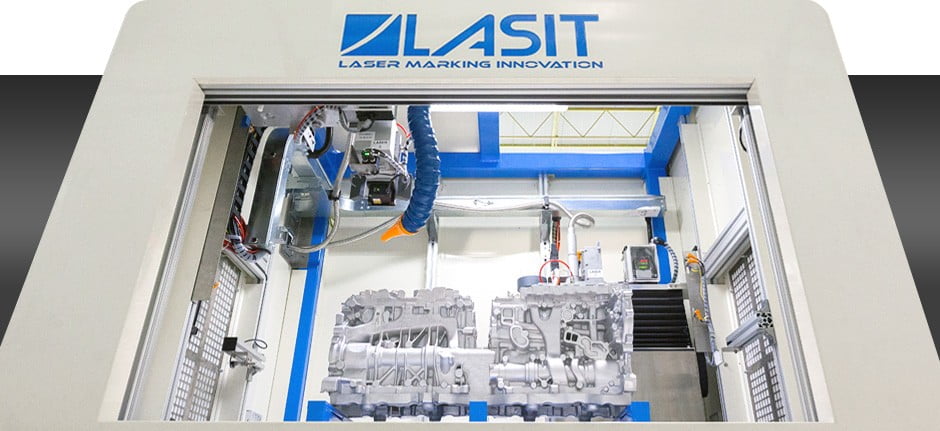

Lasit engraving machines are designed with the highest accuracy and repeatability and a full range of power levels coupled with high speed scan heads offering the fastest through put. Lasit provides turnkey systems and complete integration either with new designs or on existing production lines. Traceability solutions are developed for virtually every component as either stand alone systems or fully automated in line to meet your specified cycle times.

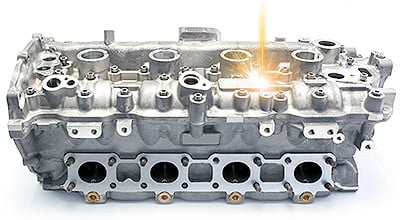

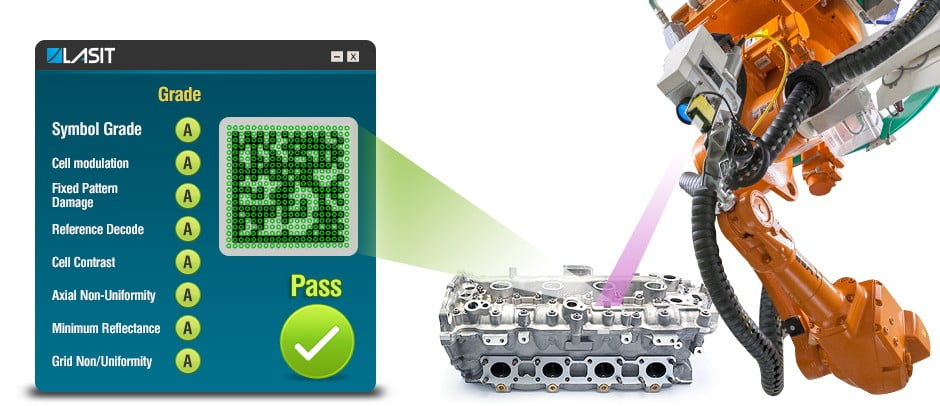

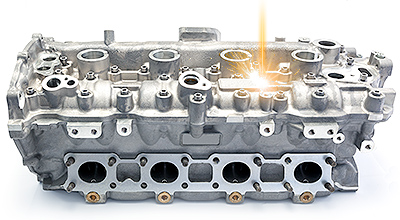

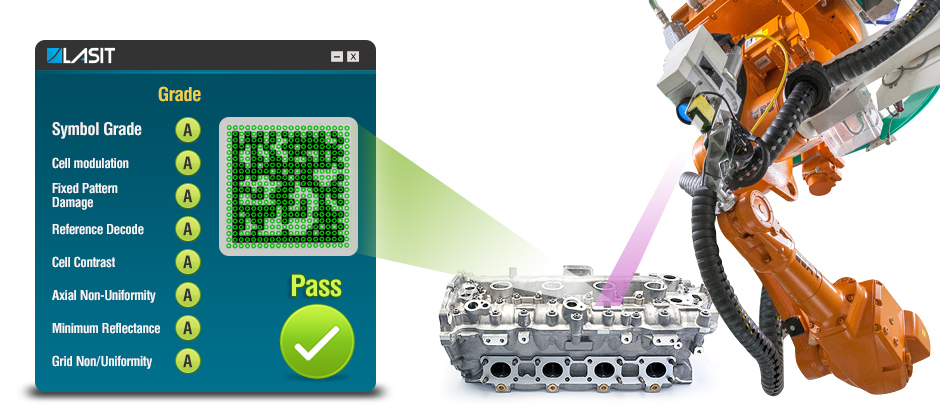

Lasit’s newest generation of laser marking systems for automotive industry makes it possible to mark, engrave, read and also verify both square and rectangular datamatrix codes. The verification of the datamatrix is done through an ISO/IEC, AIM-DPM norm. With the use of proprietary software, the marking can be read even after passivation, and nitriding or distension processes in accordance with legislation requirements. There is an inherent error correction system (ECC200) which guarantees readability of the datamatrix with up to 30% damage of the image. The cost effective, low maintenance systems are designed ergonomically, and offer increased flexibility providing marks on virtually all metals and plastics with flat, curved and cylindrical surfaces.

Vision is standard with the system and can be customized according to specific requirements. Cameras are used with a high quality CCD sensor (Charge Coupled Device) allowing for optimal and expanded field of vision depending on required dimensions. The (SLR) vision system can be designed to manage and view marks with great detail from medium to large fields. Alternatively, the TTL (Through the lens) vision system, is the ideal solution for centering marks on small parts that require extreme precision and very high definition.

The most versatile laser engraving machines in the world

Designed for perfect marking

With over 27 years in the industry, Lasit is able to offer complete custom automation solutions with standard components taking out the high cost of engineering and passing the savings on to our customers. As a system integrator, Lasit fully designs and implements the entire process offering the best solution for both standard and custom applications. The entire system is built under one roof. High level in house engineering for virtually any application with mechanical, electrical and software engineers on staff as well as a complete in house CNC manufacturing machinery to keep costs down in the final product.