Industria sculelor aschietoare - solutii de marcare cu laser

Best solutions for the laser marking on cutting tool industry

Inserts, milling cutters, tips, blades, taps, countersink tools, and all kinds of cutting tools

that can be marked with the laser to create logos, texts, datamatrix features, and

QR Codes in order to identify the manufacturer and specific features of the tool.

Differentiate and personalize your tools

Laser marking is being used more and more to personalize cutting tools (for example, tips and milling cutters) with logos, texts, and datamatrix features. This serves the dual purpose of highlighting the manufacturer’s name and clearly showing the technical features of the tool.

The flexibility and ease of use typical of marking systems make it the best tool for mass production as well as for producing a small number of pieces.

Laser marking is also perfect for wood milling cutters because it ensures deep, long-lasting engraving combined with excellent aesthetic qualities for logos and characters, which is not always possible with standard mechanical engraving.

Finally, one of the advantages of this process is that it is economical. Preliminary cleaning followed by lubrication are no longer necessary because it is possible to engrave directly on lubricated parts. In fact, laser marking reduces the number of phases in production and increases efficiency and, above all, productivity.

Laser marking in a series of mass-produced items

We create custom templates for our clients that are useful in automatically marking tools in all shapes and sizes. Every template is tested by our technicians inside the marking machines during the building process in order to obtain the best solution for loading/unloading the pieces to be marked.

Laser marking on all surfaces

Laser marking processes can be carried out on tools with flat or curved surfaces and on irregular and unusual surfaces as well. LASIT offers laser marking systems for easy, immediate marking of helical and centering tips as well as micro-tips of every size in HSS (hard metal). The characters are perfectly marked on the surface and the contrast is excellent, offering perfect traceability and identification.

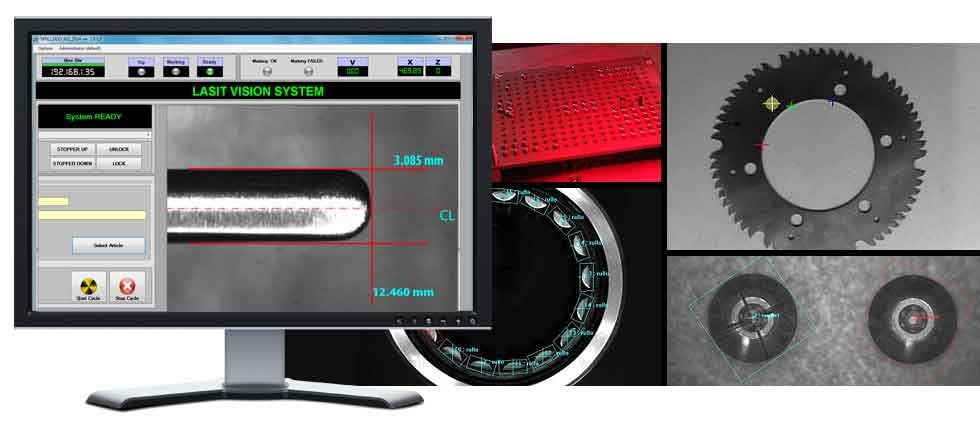

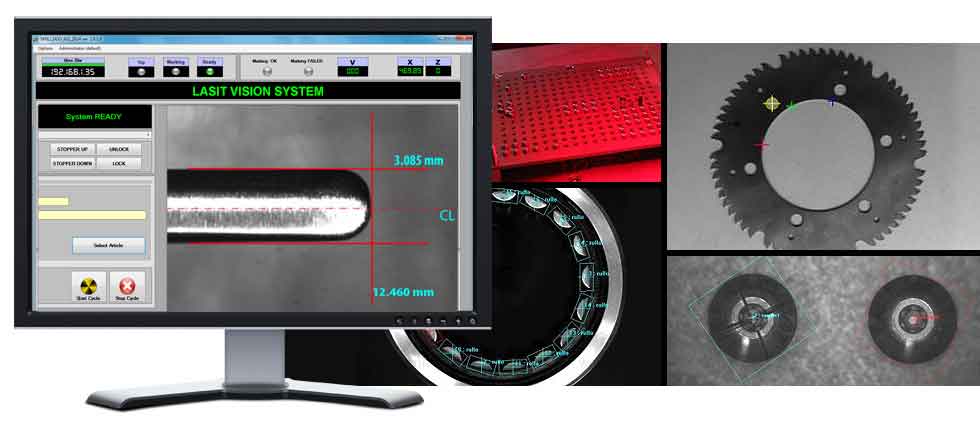

Reflex Vision System for absolute precision

The Reflex Vision System is indispensable when it comes to the precise centering of

marking when taking the geometric shape of the tool into consideration.

FlyCAD offers a real-time (LiveView) look at the area on the computer monitor in order to place the tool to be marked with ease and precision. In automatic operation mode, which is optional, the search engine of the REFLEX Vision System automatically identifies and locates the tool to be marked and moves the design in order to center it and perfectly position it for marking.

Furthermore, the system checks for the presence and correct assembly of all components. Resetting and placing thin, fragile tools in the center is very easy with the vision system and the flexibility of the programmable viewfinders. The viewfinders can be created directly in FlyCAD and are perfectly adaptable for all kinds of needs.

No tool wear

A lot of tools need to be permanently identified, but this process should not damage the material’s characteristics or the surface finish.

With our marking and laser engraving systems, excellent results can be obtained without compromising the integrity of the component.