Marcare laser pe folii si vopsele

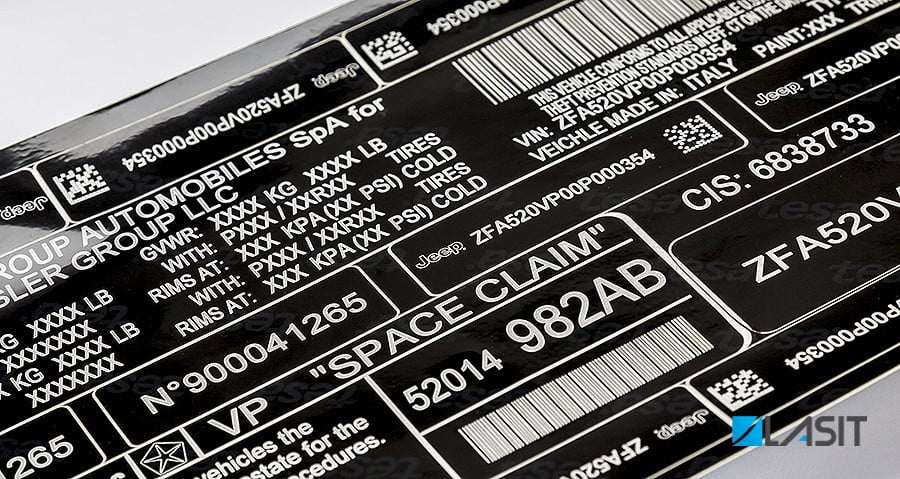

Laser engraving has completely replaced screen-printing in several applications, especially in the production of pieces used in so-called “day & night” applications. In fact, using the laser, it is possible to have perfect control over the quantity of removed material and thus the depth of the laser engraving as well as being able to perfectly define the size of engraved lines and improve definition in the corners. This results in enhanced appearance and, most of all, a significant increase in productivity.

Laser engraving on Tesa

Our laser systems offer the best engraving solutions for a wide variety of materials, including acrylic, wood, papers, and textiles. All designs are accurately and quickly laser cut using a graphic software program (e.g. CAD, Illustrator, Corel Draw), making for clear results and clean edges.

How does laser engraving on foils and paints work?

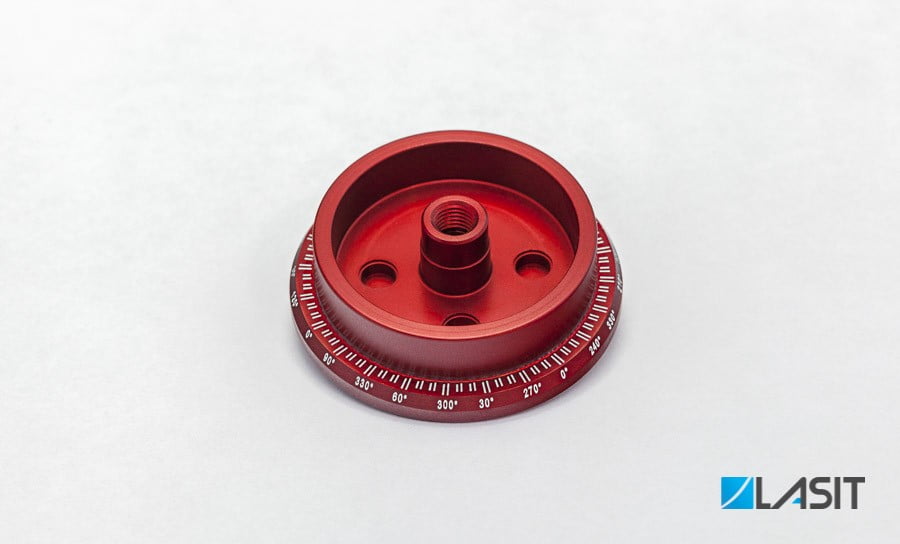

The laser is able to precisely remove and carbonize extremely thin paint layers from a wide variety of different materials, as foils and paints. When engraving is carried out with a laser marking machine, a bit of the material is ablated from the surface of the foil or film. The laser beam penetrates the surface and removes a part of it, creating a depression in the area. This happens with the partial removal of coating layers from the foil or film that have a markedly different color.

What are the “Day & Night” applications?

“Day & night” laser marking applications of foils and paints can be found wherever there is need for illuminated plastic-covered electronics. This process is widely-used in Automotive industry (for example for car switches and buttons) and consumer electronics. The laser selectively removes specific lacquer layers from multilayer-coated transparent parts until the correct or desired color is exposed.