Marcare laser pe metale si aliaje

The use of technology for the laser marking of metals has become a benchmark for doing extremely accurate and perfectly legible jobs in increasingly shorter times. This system is increasingly common in many sectors: electronics, mechanics, automotive industry, jewellery, medical technologies.

It is not just on soft metals, like aluminium, that laser marking can be done, but also on steel and hard alloys. The list of metals that can be processed includes: copper, iron, ferrous metals, brass, gold, silver, platinum, palladium, and titanium. Depending on the customer’s requirements, laser marking systems can be developed for processing every kind of metal.

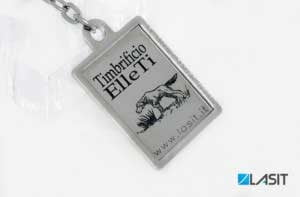

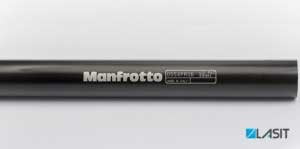

Whether we are talking about laser marking for identifying a product or deep laser engraving, surface blackening (annealing) or 3D engraving, the laser process for marking metals has considerable advantages: it is an extremely accurate and clean method, carried out by a no-contact process that requires no prior or subsequent processing ; it guarantees the identification and traceability of the products with a high resolution finish, it ensures long-lasting jobs, resistant to acids, chemicals and corrosion, without damaging the surface of the material.

Our laser systems for marking metals include the innovative fibre sources technology, which is extremely reliable for processing different metals. Since they adapt to the specific properties of the material to be marked, Lasit markers offer the best combination of marking safety, speed and quality.

Which are the main applications of laser marking on metals?

Typical industry solutions for metal laser marking and engraving include all the sectors where accuracy and precision are required, such as Automotive, product labelling and coding (serial numbers, codes and logos), Cutting tool industry and Medical Industry.

Can a laser engraving machine for metals mark all kinds of metals and alloys?

All types of metal can undergo laser marking or laser engraving. The list of metals that can be laser marked or engraved includes all types of steel (stainless, high quality, or carbon steel, etc.), but also copper, iron, ferrous metals, magnesium, aluminum, gold, silver, platinum, titanium and more.

Which is the best laser source to mark, or engrave or cut metals and alloys?

The fiber laser is the best laser source to process metals and alloys. LASIT produces the FiberFly laser that uses the most innovative technology with active fiber doped with Ytterbium. It is the ideal laser solution for precision laser engraving, marking, micro-machining and cutting of metal materials.