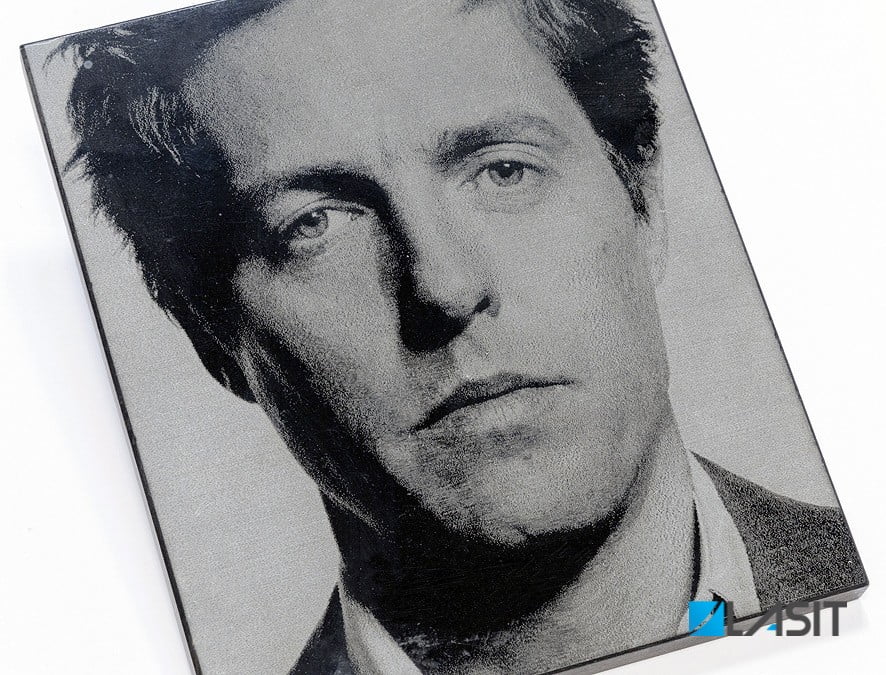

Marcare si gravare laser metaloizi si nemetale

Metalloids and non-metals can all be laser marked. However, the most important issue is the type of result you would like to achieve. A CO2 laser can be used for engraving ceramics, although there will be no color alteration in the material. If a high-contrast marking (i.e. the color alteration of the material) is required, only the YAG laser will be able to accomplish this. Just as with plastics, metalloids and non-metals must also be tested in the laboratory in order to determine the robustness of the materials.

What are the industrial applications of laser marking on metalloids?

Metalloids (or semiconductors) play an important role in our everyday lives because they are important components of electronic devices, such as computers and mobile phones. Silicon in particular is a crucial element in microelectronics and computer chips. A laser marking system can quickly mark logos, serial numbers, bar codes, or QR Codes on these tiny components. This process is sometimes impossible to accomplish with other marking systems or, if it is not, can often be very expensive while a laser marking system has a relatively low price and it guarantees high productivity and flexibility.

Which is the best laser source to laser mark metalloids and non-metals?

It is impossible to make a general statement about laser marking on metalloids and non-metals, because it always depends on the characteristics and the properties of the specific component. We provide a wide range of laser sources (fiber laser, UV laser, green light fiber, green light diode, CO2) in order to meet all kind of exigence. As a matter of fact, a CO2 laser is mainly suited for working on silicon because of its wavelength (which is 10 times longer than a fiber laser), but a fiber laser would be the best laser solution for elements as carbon. LASIT manufactures respectively FlyCO2 and FiberFly both designed for high productivity while at the same time reducing operation costs.