Masina de masurat in coordonate 3D Altera M

The LK Metrology range of Coordinate Measuring Machines represent the ultimate in CMM technology. Designed and manufactured using only the highest quality materials, they carry a heritage of over 55 years experience and expertise. LK CMMs deliver the ability to perform dimensional, positional and surface measurement in a single system. Combined with a complete range of contact and non-contact sensors, LK Metrology CMMs provide true multi-sensor capability. Sensors can be quickly changed to combine geometric and surface measurement into a single inspection routine.

Key benefits

- Complete range of premium bridge, gantry and horizontal arm CMMs

- High velocities/accelerations for low cycle times

- Excellent accuracy and repeatability

- Total solution for probing, scanning and digital inspection

Designed for smooth measurements and long-lasting accuracy

The superior ceramic design, with near perfect stiffness-to-weight ratio and greater resistance to temperature shifts, provides consistent performance across all manufacturing environments. Advanced multi-sensor ready technology optimizes CMM throughput and provides the opportunity to broaden the application scope to new materials and components as needs change. Innovative work-flows and intuitive software features facilitate complex inspection tasks and boost productivity.

- Ceramic bridge and spindle provide a thermally stable and ultra-stiff frame for long lasting accuracy.

- Unique LK air bearings provide a smaller air gap with greater stiffness than standard air bearings to enhance the rigidity of the frame.

- Granite table with integral dovetail guideway provides the smoothest of drives with high velocity and acceleration.

- Steel support legs designed on CAD with Finite Element Analysis provide a stable mounting for the ceramic beam and carriage assembly

- Friction-driven axes remove the uncertainty of belt drives and gear-boxes and provide a hysteresis-free smooth repeatable motion.

- Superior pneumatic self-levelling vibration isolation for optimum performance in areas subject to high levels of low frequency vibration.

- Bonded Renishaw scales negate the need for separate scale and mechanical frame thermal compensation, providing confidence in repeatability and accuracy.

Optimal performance and user friendly operation

Fly mode

The Fly mode provides optimized motion control for more efficient machine movement and faster throughput.

PH Fast

Further optimize the machine throughput by moving the probe head simultaneously with machine motion.

CMM Hand-box

Multi-function hand-box provides access to programming tools without returning to the computer.

Probing and scanning made easy

LK Metrology is part of the Renishaw Changers Program promotion.

PH10T, PH10M, PH10MQ and PH20 probe kits include one of the following offers.

- FREE stylus change rack* and probe modules with PH10T, PH10M, PH10MQ or PH20 probe heads.

or

- 50% DISCOUNTED probe change rack** with PH10M or PH10MQ probe heads.

Offer applies to new CMMs, CMM upgrades and CMM retrofits.

*MCR20, SCR200, FCR25 (not available with PH10T) or TCR20 stylus change rack included with probe kit.

** 600mm MRS rail and ACR3 probe change rack included with probe kit.

Regardless whether contact or non-contact scanning is required, LK Metrology has a solution available for highly repeatable and accurate scanning results during geometric feature and free-form surface inspection.

Unique and unequalled, digital scanning is delivered as standard on every LK CMM equipped with either TP20 or TP200 probes. This cost-effective scanning solution enhances traditional CMM inspection to increase productivity.

When accuracy and high speed are a pre-requirement, LK CMMs’ ultra-stiff ceramic frame guarantees that continuous contact scanning (SP25M) will provide you feature, form and free-form surface data that is equal to any ‘fixed-head’ probe system.

Non-contact laser scanning, with the world leading Nikon laser scanning technology, allows you to digitize virtually any component.

Suitable for geometric inspection, free-form surface inspection or reverse engineering, laser scanning is available for everyone.

When size truly matters

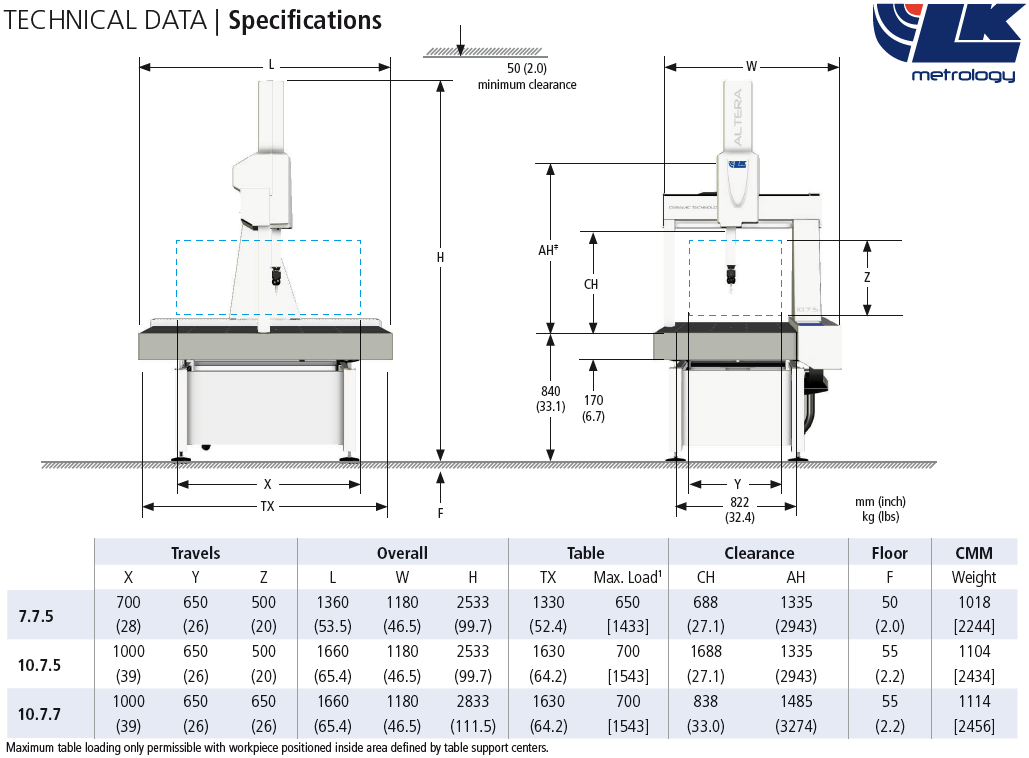

LK CMMs are standardly available in a wide range of measurement volumes.

For applications requiring specific or larger measurement volume, LK CMMs can be delivered to the customer’s needs. Whether it is a large bridge or a horizontal arm configuration you require, the LK CMMs are always based on the same ceramic and granite construction offering market leading accuracy and performance.