Sistem de exhaustare - HFiltration CeanMist

The CLEANMIST® range includes a vast series of oil mist centrifugal filters and electrostatic filters. Air polluted by oil mist or liquid coolant is channelled into the centrifugal filter, going through the intake with mesh to prevent solid materials from being suctioned.

A cone-shaped diffuser ensures the mist particles and vapours are evenly distributed inside the impeller, where they are rapidly spun and pushed towards the filtering panels. As they go through the panels, the particles undergo coalescence, transforming into droplets, which are then drained to the outside through a specific drain pipe. The purified air is thus channelled towards the upper part of the centrifugal filter, where, if necessary, it is treated with a final cartridge or with a FEF electrostatic filter.

Versions

CLEANMIST® oil mist centrifugal filter with final cartridge filter

The final cartridge filter can be from H10 85% to H13 99.96% efficient. The cartridges are also available in the active carbon version.

CLEANMIST® oil mist centrifugal filter with final FEF electrostatic filter

The FEF (Final Electrostatic Filter) works based on the principle of ionising the polluting particles. The air coming out of the CLEANMIST® centrifugal filter goes through an “ionising” section where particles up to 0.03 microns receive a high electrical charge. The air flow goes through a second “collector” section, made of plates with the opposite electrical charge. The ionised contaminated particles are thereby attracted by the plates and stick to them. The treated air is put back into the environment with 99% of the impurities removed.

Advantages

- Wide range of application

- Efficiency: up to 99%

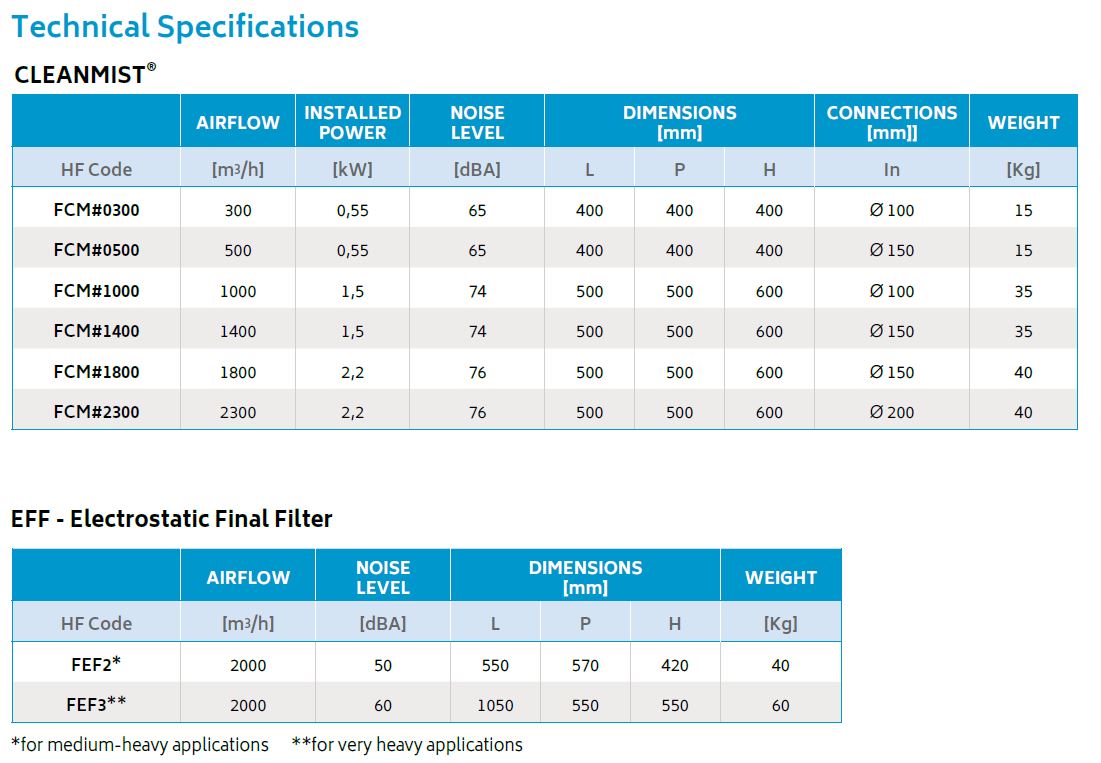

- Low Noise: 65÷76 dBA depending on the model

- Filter accessible from several parts to facilitate cleaning

- Simple installation

- Wide range of support frames

- Processing oil recovery

- Pressurised oil drainage

- Immediate delivery

- Tailored solutions and customisations

- Three filtration stages

60 Hz versions - Special colouring

- Technical service

- Support in choosing the most suitable solution, both in terms of technology and cost-effectiveness

- Turnkey installation on request

- Scheduled maintenance with our qualified technicians