Sistem de filtrare - HFiltration HJL CART

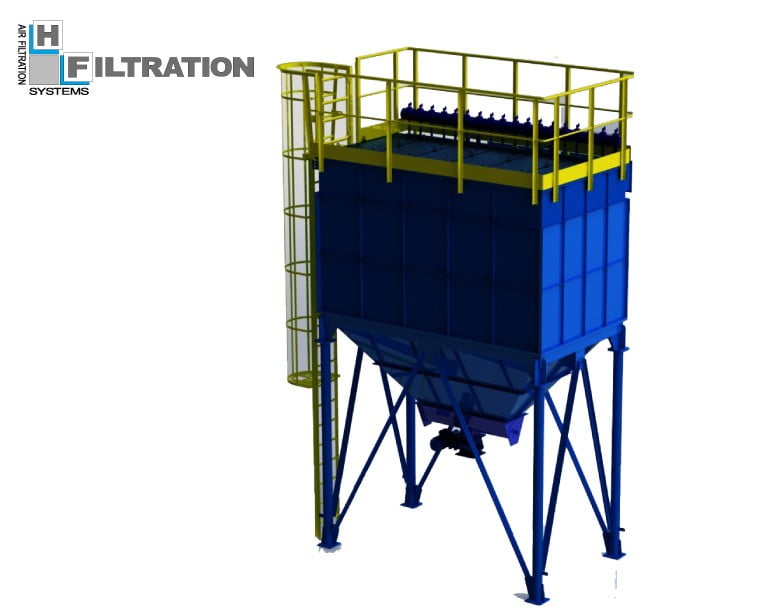

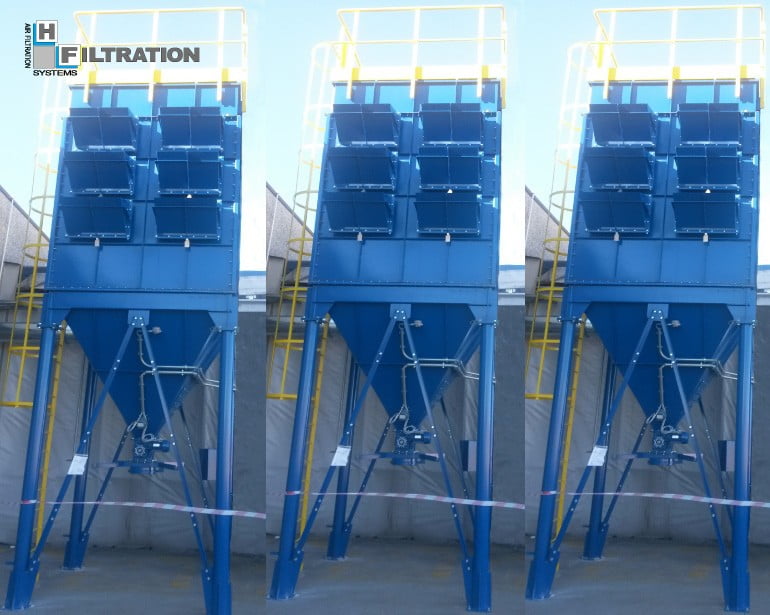

The HJL CART cartridge filter is equipment used to remove dust from gas streams.

Dust-laden gases go into the cartridge filter, where they find a pre-chamber in which the coarser particles are separated, then they go through a series of filtering cartridges.

The gases are transported by a fan installed at the end of the system, which ensures the vacuum needed for suction, keeping it under vacuum.

The material making up the cartridges is treated so as to be suitable for the type of dust suctioned and to have a permeability to allow the gas to go through, but not the dust, which, instead, sticks to it. The dust filtered by the cartridges is collected in a hopper and then expelled through a dust discharge system.

Versions

HJL CART ATEX Cartridge filter

The 2014/34/EU directive requires all products to be Atex certified if they are installed in atmospheres with a risk of explosion; HJL CART ATEX filters are CE ex IID T155°C IP55 certified to be installed in Atex 22 areas.

HJL CART ATEX series cartridge filters are.

The Ø125mm highly filtering surface cartridges, available in lengths varying from 1500mm to 2000mm, are equipped with an inner containment mesh and pressure fastening system. The inner mesh does not require a basket to be used.

The fibre making up the cartridge is chosen based on the application. The cartridge can be removed from the walkable filter roof. HJL CART ATEX filters are equipped with a counter-current Pulse-Jet compressed air cleaning system. This is mainly made up by a compressed air tank, PED certified according to the 2014/68/EU standard in ATEX version, equipped with pre-wired “Full Immersion” membrane valve with BUS management system and electronic control unit installed on the filter. To optimise cleaning system efficiency, Venturi nozzles can be installed on each cartridge. The dust discharge system is made up by an Atex collector auger at the bottom of the hopper and Atex sealed rotary feeder to unload in Big-Bags. Broken cartridge and hopper jam alarms or rotation sensors for the dust discharge system can be useful accessories.

CE ex IID T155°C IP55 marking and certification according to the 2014/34/EU directive.

Advantages

- Emissions ≤ 5 mg/Nm³s

- Limited maintenance, thanks to an efficient compressed air counter-washing system

- Extremely low installation, use and maintenance costs

- High filtration efficiency and low output emissions

- Fast, simple filtering cartridge maintenance

- Extremely low installation, use and maintenance costs

- Extensive filtering cartridge duration