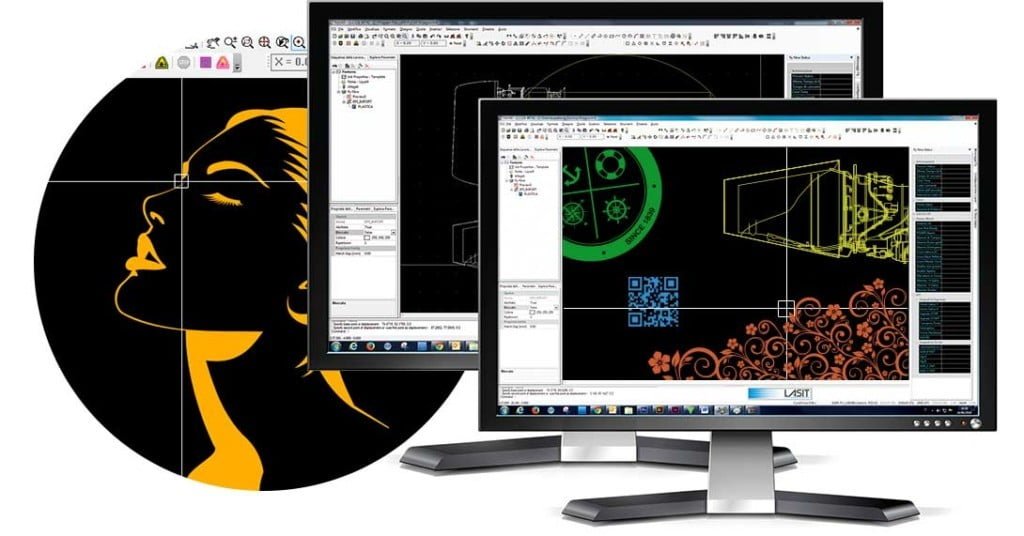

Software marcare cu laser - Lasit FlyCAD

Simple, intuitive, flexible

FlyCAD, created in a Windows environment employs the concept WYSIWYG (what you see is what you get). The simplicity and flexibility of FlyCAD allows the system to incorporate all the information necessary for laser engraving and marking (power, frequency, etc.) into one single file .dwg or .dxf. This can include any combination of True Type text, serial numbers, bar codes, datamatrix, logos, etc. The software also controls the management of the movement of up to 9 axes. As FlyCAD continually evolves all updates and upgrades are free to our customers for the life of the machine. Our software engineering team is also able to create fully customized software, graphics and interface. The software can load dynamic data, manage a customer data base, and control all automation.

Technical information

Fully customizable:

Ability to interface practically with all communication protocols (TSP, TCP / IP, RS232, PROFIBUS, etc.)

File Import:

With FlyCAD it is possible to draw directly, or import texts and/or drawings of any kind of format (DXF, DWG, PLT, AI, PDF, EPS, BMP), and if necessary, to change them.

Accuracy:

Ability to carry out lines, polylines, arcs, circumferences and fillings.

Font:

Full support for TTF fonts also in oriental language.

Text:

Text with scalable fonts. Horizontal and vertical writing mode. Text aligned to the left, right and center, or justified. Marking text in rotation with the option to set the radius, angle of departure and final.

Bar code:

Code 128, EAN8 and EAN13, code 39, code 2 of 5 and others on request

Dmx:

Fully compatible with the AIM specifications.

Date automatically:

Date generations based on a format completely configurable by the customer in any language. Integration with the axes: replication feature available in conjunction with XY tables so that you can mark a pallet of pieces automatically.

Integration with the axes:

Replication feature available in conjunction with XY tables so that you can mark a pallet of pieces automatically.

Split:

Functionality available in conjunction with XY tables. The program will automatically “cut” a bigger drawing of the working plane in several parts. At the end of this operation performed in real time, the machine positions the XY tables so as to mark the first square and then it passes to the next square to cover the total area to be marked. In this way the marking area includes the entire table.

Parameters:

Database with processing parameters of materials. able to store thousands of different parameter sets.

Counter:

Option to count the number of marked pieces and to receive a warning at the end of the process.