Tomograf pentru scanarea rezervoarelor

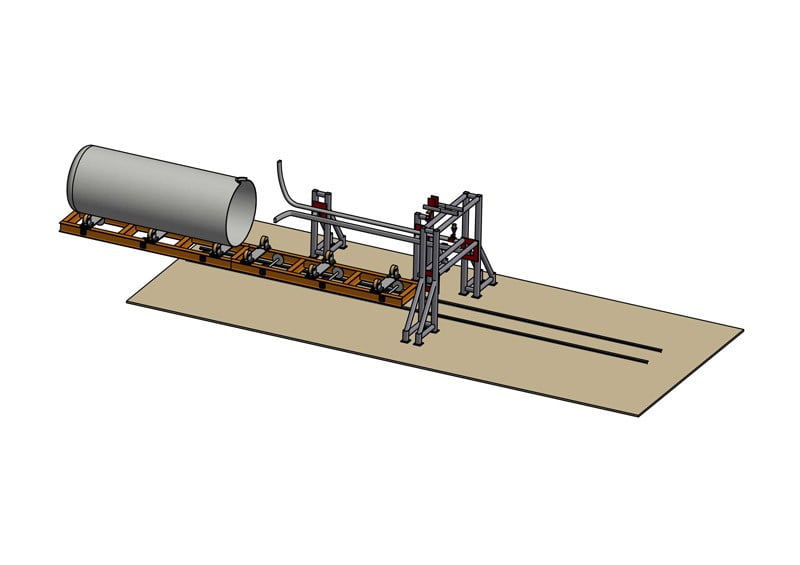

The inspection of welded tanks is a time-costly procedure. Modern real-time DR-systems result in a huge efficiency gain in comparison to the conventional film (RT) approach. VisiConsult developed a cutting edge custom system with weld tracking, defect marking, automated handling and much more.

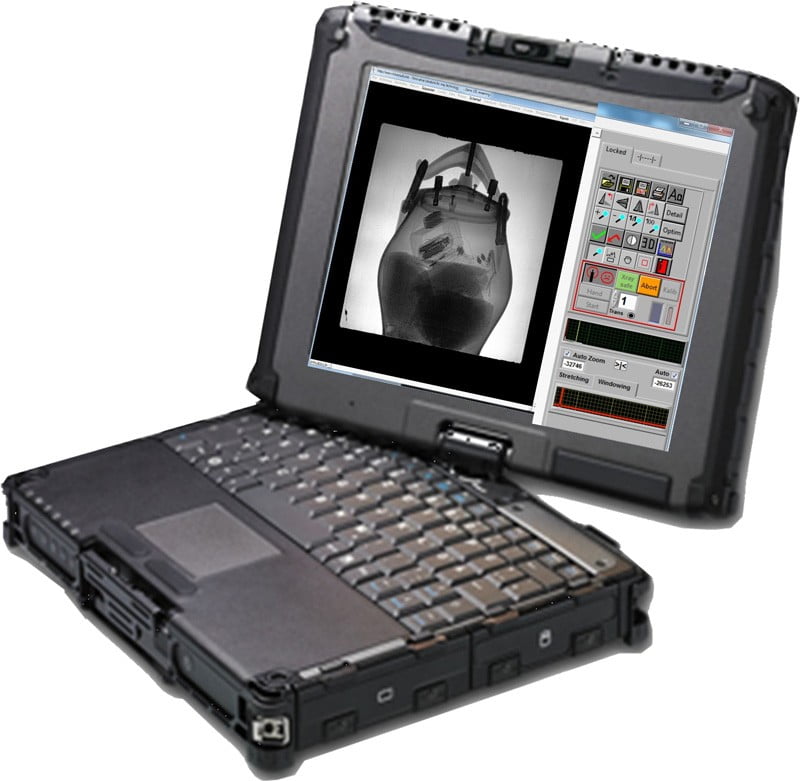

To prove the product quality, tank manufacturers have to perform an X-ray inspection in compliance to EN-17636. Every weld has to be inspected and the result has to be archived. This time-consuming task can bind a lot of manpower and cause a bottleneck in production output. The XRHTank combines the sophisticated Xplus image enhancement system with automated part handling even for heavy and big tanks.

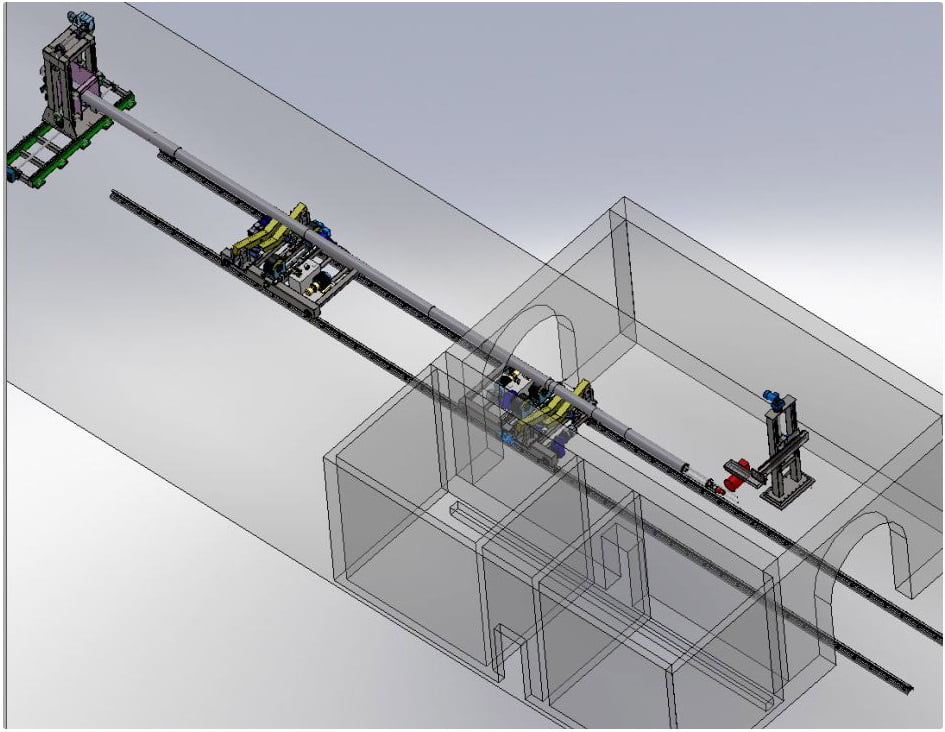

The goal was to create a system that offers the highest degree of automation, simple handling and excellent image quality. The XRHTank can inspect longitudinal, circumferential and even spiral welds. Proven through reference installations globally, every system can be customized to specific products, inspection processes or space availability. In the most advanced version the XRHTank can even inspect the manhole and connection weld automatically. An alternative is the manual test of these complex structures through CR plates.

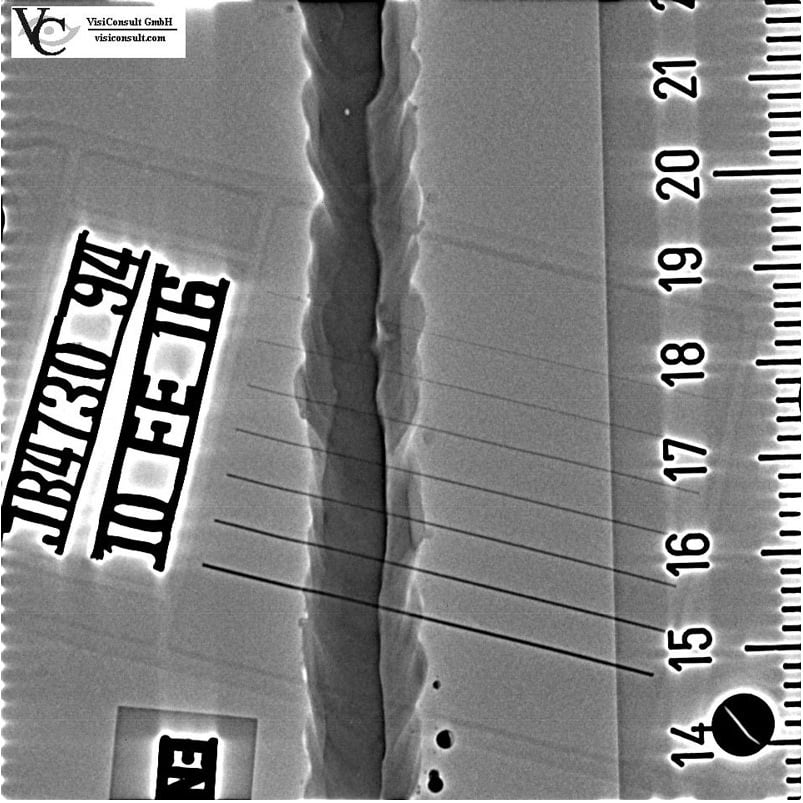

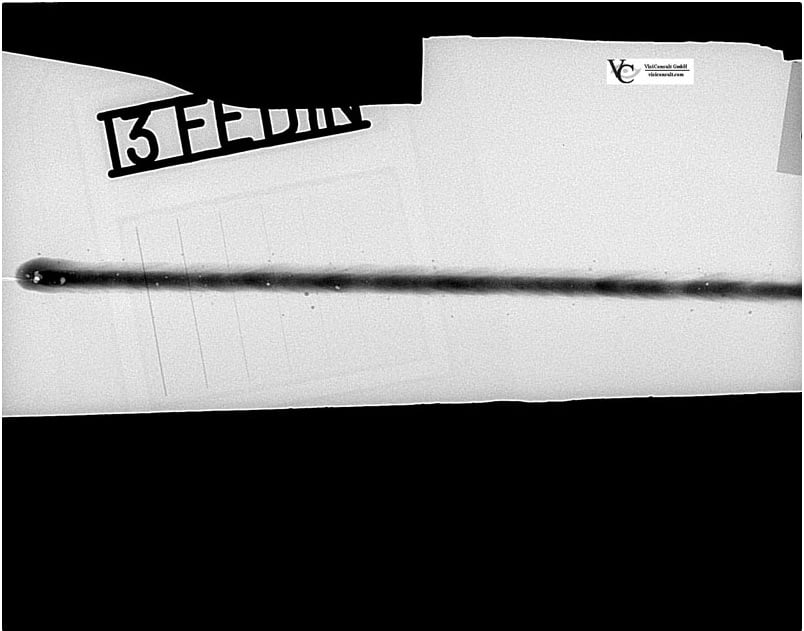

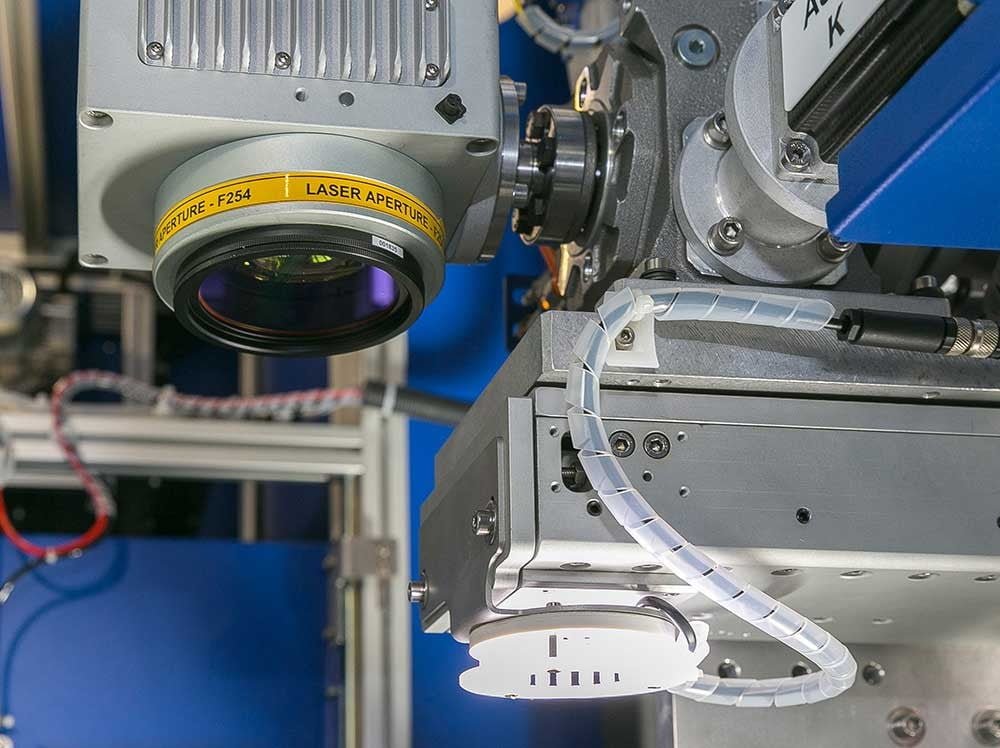

The Xplus image enhancement system provides a broad portfolio of tools to increase the image quality. Most important is an advanced noise reduction that is compliant to EN-17636. To assist the operator a variety of filters highlight the defects for further inspection assistance. To store the images in respect to archiving standards and policies customers can choose from different platforms like DICONDE, image-file plus overlay, databases and many more.

- Xplus: Brilliant images and comprehensive decision assistance features

- Reliable storage in DICONDE, image archives and databases

- Certified resolution and contrast verification in compliance to EN-17636

- Automated part handling for big and heavy tanks, vessels and boilers

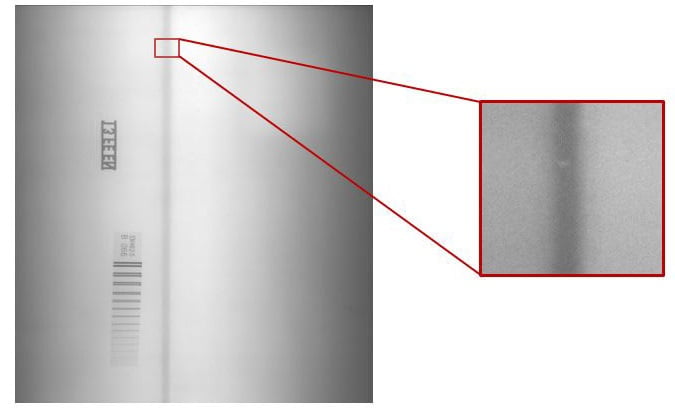

- Detection of welding defects like porosities, inclusions, cracks etc.

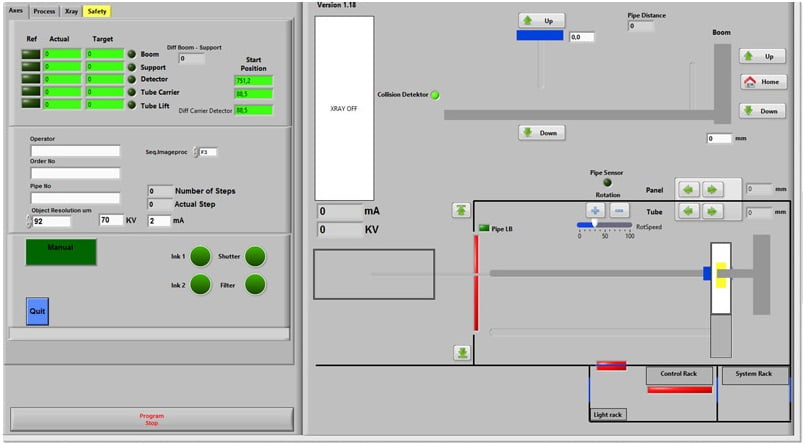

To increase the throughput, the control software Xplus Handle offers a high degree of automation. Inspection will become as easy as pressing a single button: On startup the tank moves into the system, the tank length is detected to close the doors as early as possible. A sophisticated collision detection model prevents damage to the system and products.

During inspection the tank moves stepwise by tracking the welding line. The operator can perform image enhancement filters or add comments in every step. The system will follow each circumferential and longitudinal weld as defined in the inspection sequence. That means the operator just has to do the actual decision supported by comprehensive assistance tools. Every other step is automated. To increase the throughput even more the inspection can also be decoupled from the image acquisition.

In case of a desired real-time inspection the XplusVCR module adds a high quality video recorder to the inspection tools. Together with a real-time panel the complete inspection procedure can be archived if required.