Bilz Self Reversing Tapping Attachment TA

Application

Application: tapping, roll forming on machines with a driven spindle and manual feed

Machine type: drilling machines, machines with driven spindle

Features

- quick change system for tap adaptors

- exchangeable, screwed-in shank

- double feed rate on reverse motion

- no built-in safety clutch in the unit

- free of maintenance

- unit can be used for right and left handed threads

- integrated reversible gear

Advantages

- quick tool change – no additional tools required for the tool change

- higher flexibility – by changing the shank, the unit can be used on different machines with other spindle locations

- shorter processing time due to higher feed rate on reverse motion – shorter processing time

- unit price is cheaper – application adaptors with safety clutch only when it is necessary e.g. ground holes

- no down time due to service of the unit – reduction of the down time, no spare units required

- just one unit required – reduction of the number of tools

- self reversing by using the length compensation of the unit – time reduction due to not reversing the machine spindle, machine protection due to not slowing down and speeding up the machine. Energy saving!

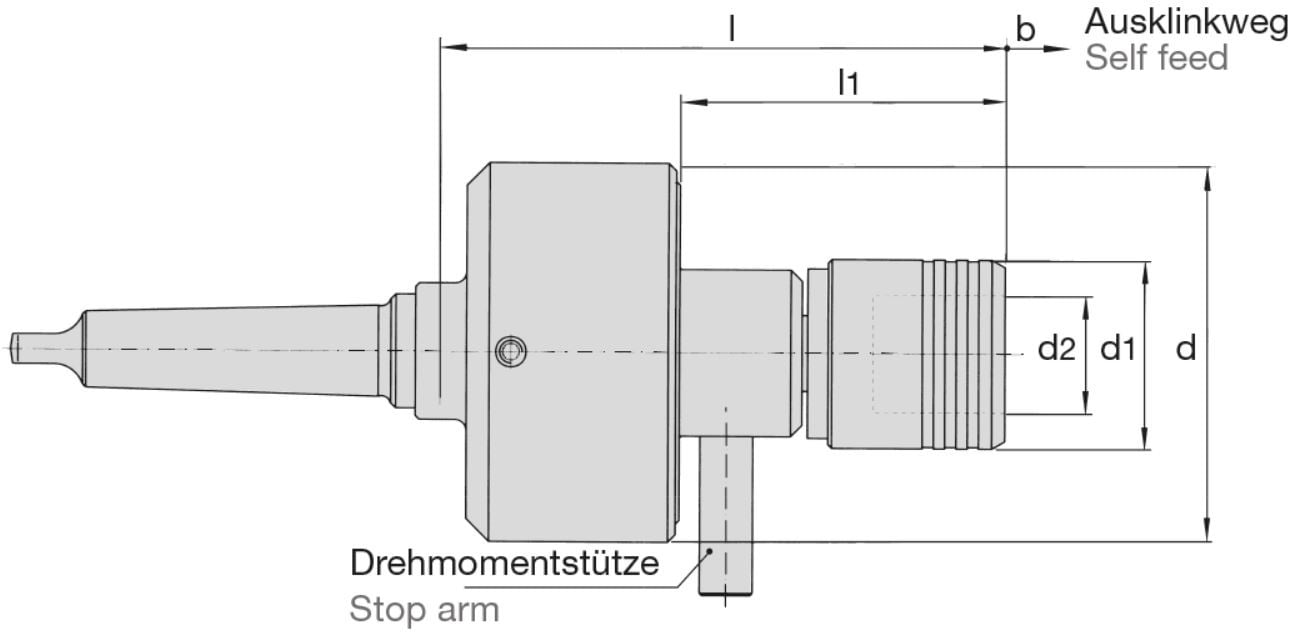

Description / Qualities

This self reversing tapping attachment is designed for use on drilling machines which have only manual feed facilities and which do not have a reversible spindle. The tool design is simple, effective, and is virtually maintenance free. The unit is fitted into the machine spindle by virtue of its morse taper shank, with the stop arm located against the column of the drilling machine to ensure effective and positive action. The design of the units is such that it can be used for either right or left handed tapping operations.

The design of the unit is such that tapping and reversing is possible without changing the direction of the machine spindle.

The unit automatically changes direction when the required thread depth has been achieved. The unit accepts both Bilz WE and WES tap adaptors which facilitate quick tap change, a separate tap adaptor is required for each size of tap shank. The use of WES tap adaptors gives additional security against tap breakage by means of the clutch mechanism.