Industrial Computed Tomography Nikon XT H 320 for X-ray and CT inspection of larger samples

XT H 320 for X-ray and CT inspection of larger samples

The XT H 320 features a more powerful microfocus X-ray source that is able to run highly accurate inspection on dense industrial objects. Nikon Metrology is the only company to produce 320 kV microfocus X-ray sources. As the X-ray spot size of these sources is orders of magnitude smaller compared to minifocus sources, end users benefit from superior resolution, accuracy and a wider array of measurable parts.

Benefits

- Proprietary 320 kV microfocus X-ray source

- Run highly accurate inspection on dense industrial objects

- Easy system operation and low cost-of-ownership

- Stunning images providing great insight

- High performance image acquisition and volume processing

- Straightforward inspection automation

- Safety first

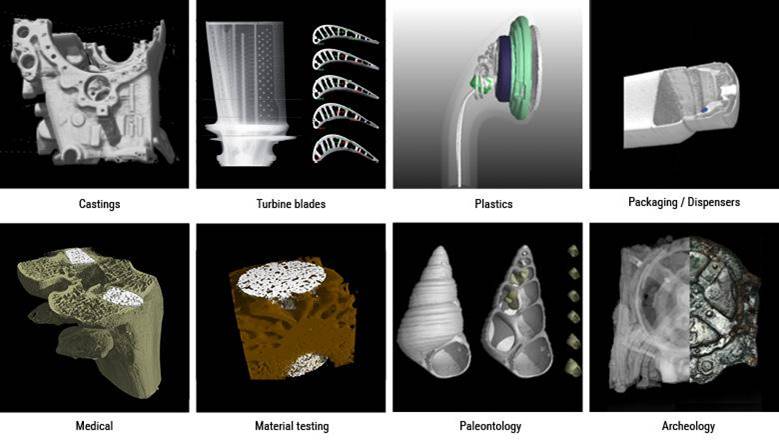

Applications

- Fault detection and failure analysis

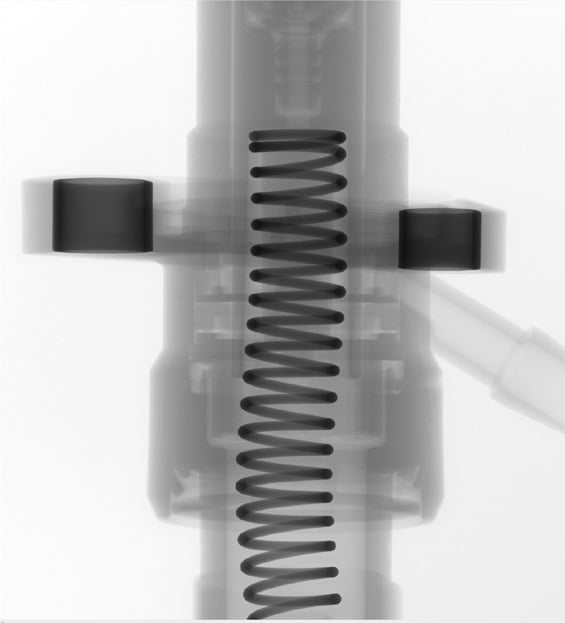

- Assembly inspection of complex mechanisms

- Dimensional measurement of internal components

- Part-to-CAD comparison

- Advanced material research

- Analysis of the biological structures

- Digital archiving of models

Benefits & features

Superior accuracy and performance through proprietary 225 or 320kV micro-focus X-ray source

The default 225 kV microfocus source is equipped with a reflection target, offering a 3 micron spot size. With the optional transmission target, you obtain an even smaller spot size and higher magnification capability.

The 320 kV microfocus source is used to penetrate through larger or denser samples.

Regardless of the target of choice, the XT H large cabinet system uses an open-tube X-ray source that guarantees a lower cost-of-ownership

Stunning images from internal structures

A small spot size and a high-resolution flat panel create sharp images. Adapt resolution to your needs: full part in coarse resolution and high resolution in a desired region of interest.

Easy access to inspect larger parts

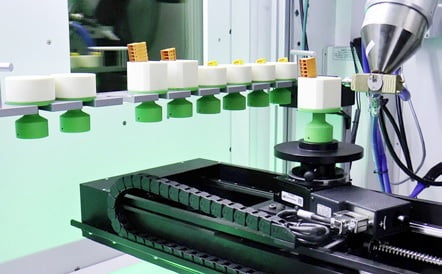

The XT H 320 systems feature a large access door and the heavy-duty precision 5-axis manipulator can hold samples in excess of 50 kg with dimensions of 0.6 m (H) x 0.6 m (D).

Safety first

Full protective enclosure – compliant to CE and DIN 54113 radiation safety standards – requires no special badges or protective clothing. Continuous fail-to-safe monitoring during system operation. Radiation shielding is to better than 1µSv/hour external, and dual fail-safe switches/relays ensure safe operation

Low cost of ownership

The open X-ray tube allows for local maintenance of internal tube components and allows the operator to replace the tungsten filaments easily.

Configure the system to your specific needs

Specific applications require more detailed images or higher accuracy. XT H 320 can be configured with different flat panels (Varian, Perkin Elmer) or source configuration (reflection/ transmission target) to make the system ideally suited for your needs.

Download the brochure