LK HD90 Coordinate measuring machine

LK HD90 Coordinate measuring machine

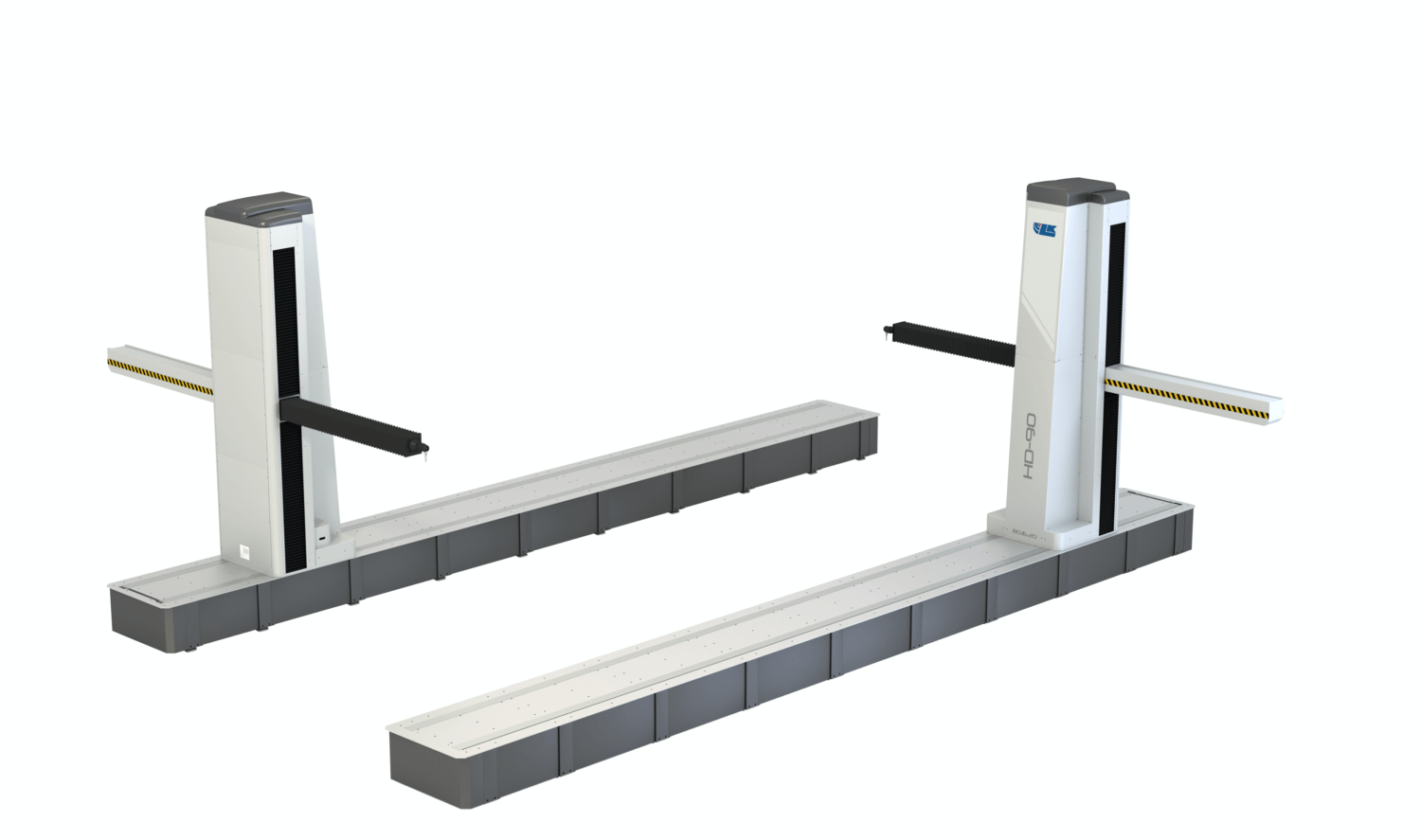

HD-90 is a heavy-duty ultra reliable high-performance CMM for deployment in production and shop-floor environments, developed specifically for car-body and sub-assembly quality control applications.

HD-90’s Runway design is specifically developed for single or double arm configurations. It is totally encapsulated in protective covers to ensure thermal insulation against environmental changes while protecting the system from the contaminants typically found in a workshop environment.

The open structure can be installed floor level or on the floor, the walkable guideways protect the X slideways and the completely encapsulated structure guarantee maximum accessibility in safety to the measurement area while simplifying manual or automated part loading and unloading operations, as well as allowing a safe utilization directly in any production area.

Air bearings for the Y and Z axes, double recirculating bearing guideways for the X-axis and DC motors are the key elements for this high-speed metrology solution.

For the double arm solution the measurement volumes of the two horizontal arms overlap each other by 100mm in order to ensure complete access to all the features to be measured on the component.

Highlights:

- Measurement system with linear optical transducers

- Control of movement through DC servo motors

- Air bearings on the YZ axes, double recirculating bearing guideways on the X-axis

- Mechanical carrier counterbalance with safety brake

- No specific need for foundations unless specifically required

- On the floor or floor-level installations with heavy-duty walkable guideways

- Cast iron work-plates and loading/unloading systems are optionally available.

The HD-90 CMM Series is available in XX standard sizes with the following YZ axes sections: 16.20 / 16.25 / 16.30.