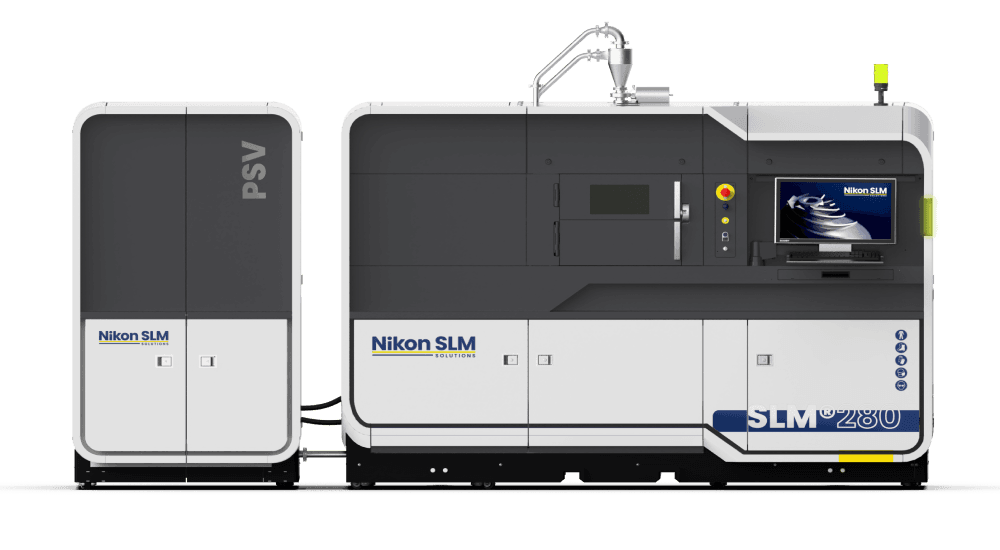

Nikon SLM Solutions - SLM®280 PS

Enhance your manufacturing capabilities with the SLM®280 Production Series. Engineered for precision and efficiency, this powerhouse metal 3D printing system is ideal for industries requiring high-quality metal components at scale. With its customizable solutions and seamless integration into existing workflows, the SLM®280 PS empowers you to meet the demands of today’s dynamic market with confidence.

Consistent Results

The patented multi-laser scan strategy of the SLM®280 PS ensures consistent results with the same density and mechanical properties as single-laser builds, minimizing variability and ensuring reliable outcomes.

High-Volume Manufacturing

With a build plate 25% larger than standard mid-sized machines, the SLM®280 PS maximizes productivity by accommodating more parts per build, making it ideal for high-volume manufacturing applications.

Clean Process Environment

Featuring a patented laminar gas flow, the SLM®280 PS creates a clean process environment throughout the build, enhancing quality and minimizing contamination risks.

Uptime Improvement

The production-geared permanent filter module of the SLM®280 PS improves uptime by trapping soot and condensate particles from the process gas stream, reducing maintenance downtime and ensuring continuous operation.

Cost Reduction

By purging waste material from the filter with gas and dropping it in a bin for dry disposal, the permanent filter module of the SLM®280 PS reduces costs associated with filter replacement and maintenance.

Enhanced Safety

Closed-loop powder handling in the SLM®280 PS increases safety by containing and managing powder throughout the printing process, minimizing contamination risks and ensuring operator safety.

Material Quality Assurance

The closed-loop powder handling system of the SLM®280 PS maintains material quality by preventing contamination and ensuring consistent powder properties throughout the printing process.

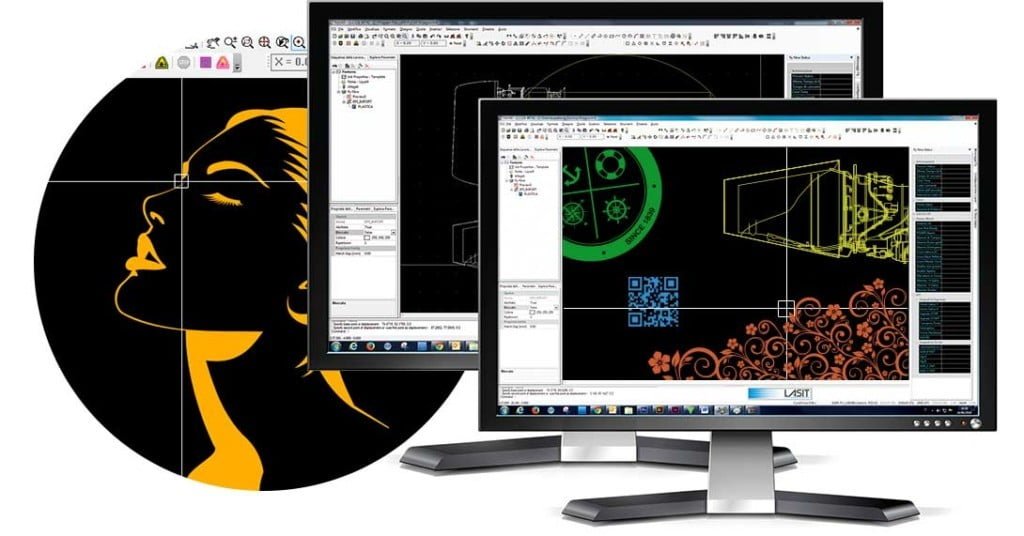

Efficient Workflow

Advanced software compatibility and intuitive interface design on the SLM®280 PS streamline operation and enhance user experience, ensuring a seamless workflow from design to production.

Precision Engineering

Utilizing high-precision laser technology and advanced thermal management systems, the SLM®280 PS ensures exceptional part accuracy and surface finish, meeting the most stringent quality standards.

Scalability

The SLM®280 PS is designed for scalability, allowing seamless integration into existing production lines and facilitating the expansion of additive manufacturing capabilities to meet growing demand.