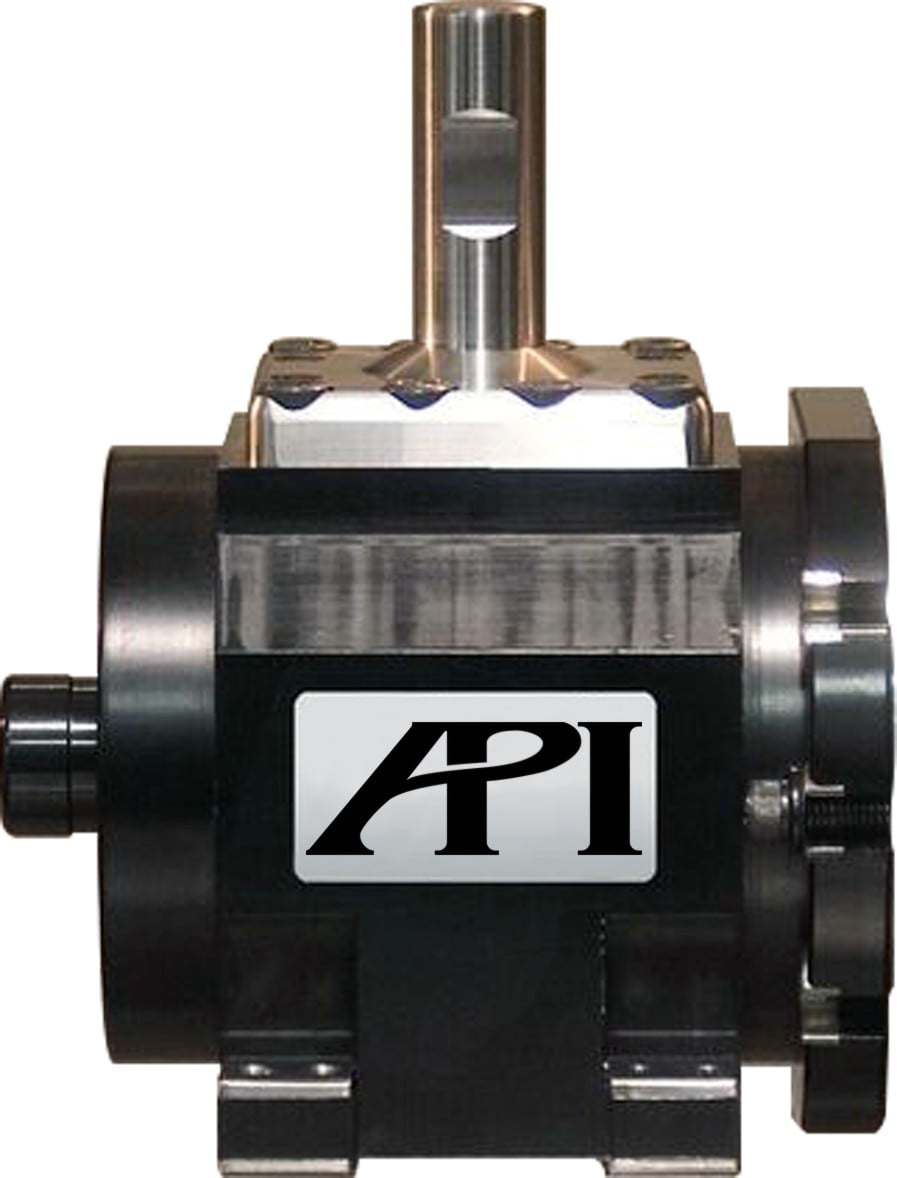

Swivelcheck™

Increase Manufacturing Efficiency

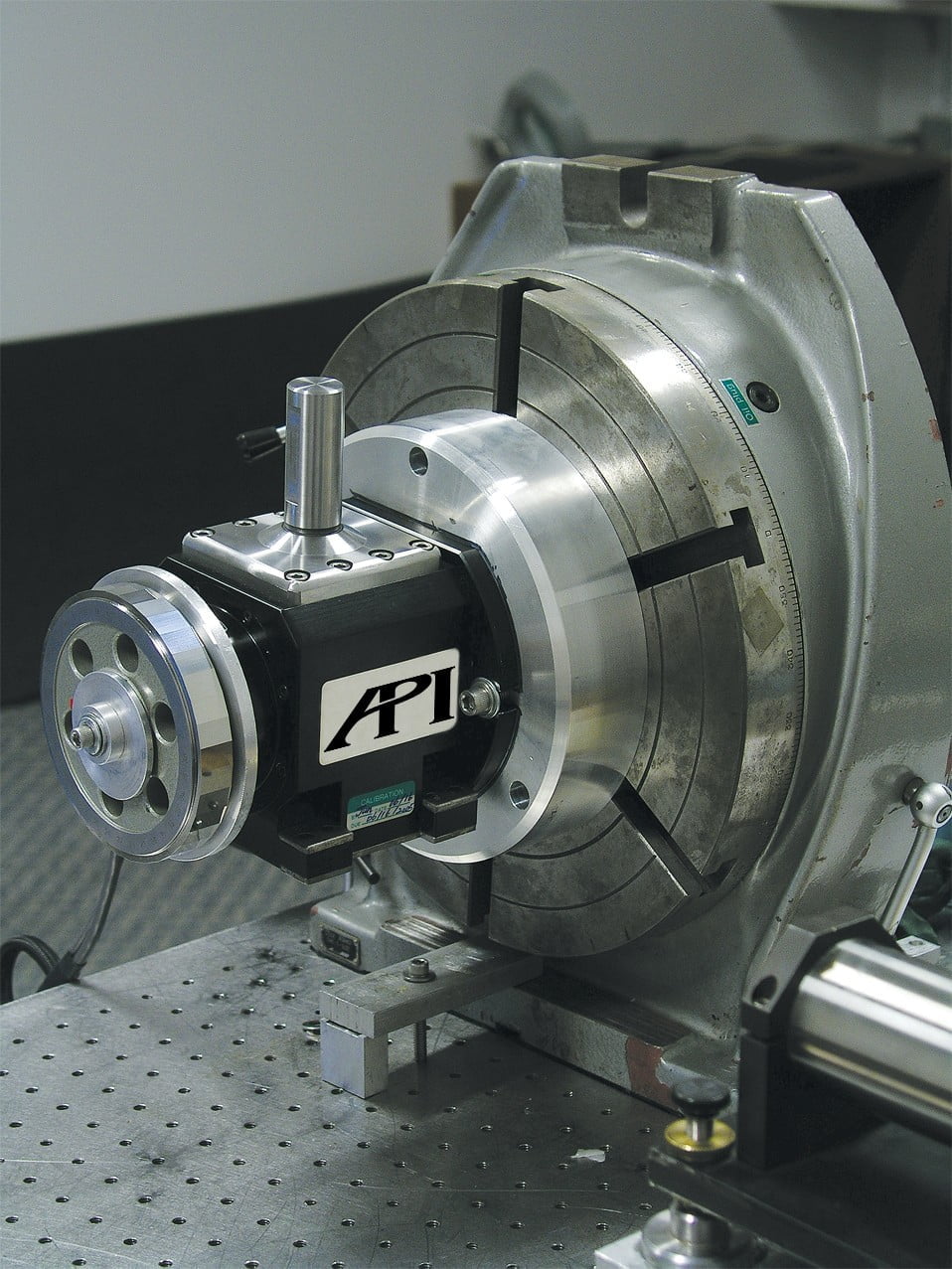

The revolutionary Swivelcheck™ from Automated Precision Inc. (API) is a one-of-a-kind instrument used to measure rotary axes and tables in the CNC Calibration process. This instrument calibrates swivel axes and tilt tables on machine tool centers; evaluates vertical rotary axes and table performance; and measures horizontal tables and axes when used with API’s XD™ Laser.

So How Does It Work?

The Swivelcheck™ utilizes a servo-driven motor in conjunction with an electronic level and a precision rotary encoder. Once set up, the system is capable of running in automated or manual modes. The Swivelcheck™ has been designed with ease of use, efficiency, and accuracy in mind and is the rotary axis instrument of choice for professional machinists.

Features of the API-Exclusive Swivelcheck™

- Rotary and vertical measurement from a single setup

- Automated or manual axis measurement

- Zero anywhere functionality for efficient measurement

- Able to mount off-axis for easy setup

- Ethernet communication

- Fully portable

- Highly accurate

Download the brochure