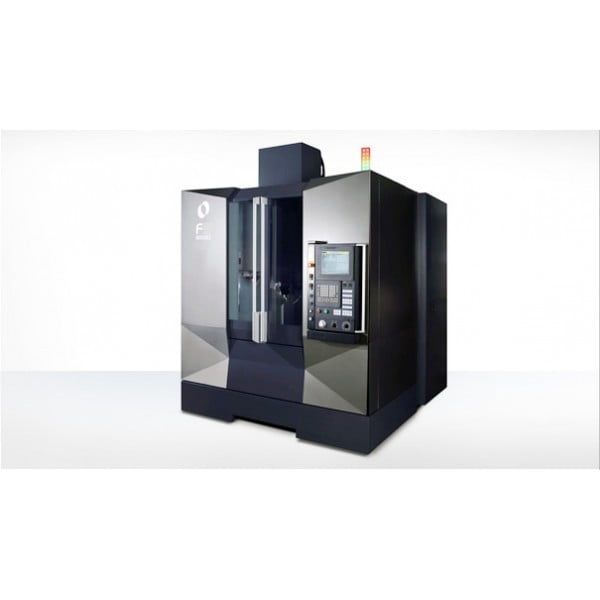

N2-5XA Horizontal Machining 5 Axis N2-5XA

Horizontal Machining Center Designed for Medical Part Machining

The N2-5XA 5-axis horizontal machining center is specifically designed for high-productivity in near-net-shape components, making it ideal for medical part machining of orthopedic implant parts and high-volume die cast component production. Its twin direct-drive rotary axes are housed in a rigid trunion casting, providing ideal accessibility to the workpiece and opportunities to improve quality and throughput by consolidating operations. The N2-5XA features a 20,000 rpm HSK-40A spindle that accelerates to maximum RPM in just 0.8 seconds. This spindle works in concert with the standard AI Contour Control and 1.4G Z-axis acceleration to quickly and accurately produce the complex geometries common in medical implant components. Consuming a mere 26 square-feet of floor space, the N2-5XA is a high-productivity “right-sized” solution to your small part manufacturing challenges.

| Pallet | 200 mm ø |

| X | 300 mm |

| Y | 300 mm |

| Z | 230 mm |

| A Axis | 150° (-120° ~ +30°) Direct Drive |

| B Axis | 360° Direct Drive |

| C Axis | n/a |

| Spindle RPM | 20,000 |

| Rapid Traverse | 42,000 mm/min (X&Y), 56,000 mm/min (Z) |

| Cutting Feedrate | 32,000 mm/min |

| Maximum Workpiece | 300 mm ø x 270 mm (with limitations) |

| Maximum Payload | 150 kg |

| ATC Capacity | 14 (21 opt) |

| Tool to Tool | 2.5 |

| Chip to Chip | 4.3 |

| Maximum Tool Length | 150 mm |

| Maximum Tool Diameter | 50 mm |

| Maximum Tool Weight | 2 kg |