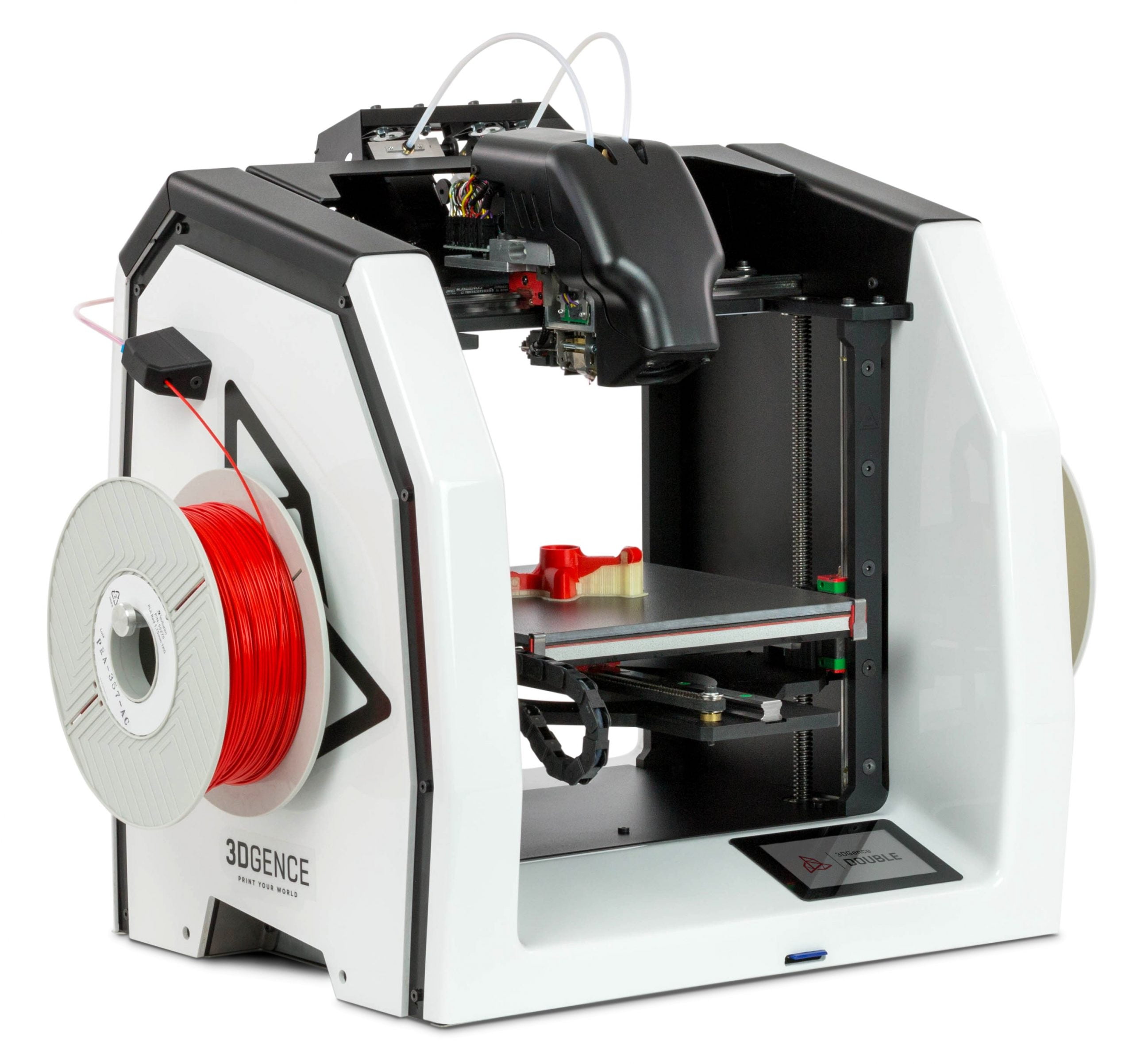

3DGence Double P255 - dual extruder 3D printer

3DGence Double P255

Dual-extruder 3D printer developed for professional use certified by TÜV Rheinland.

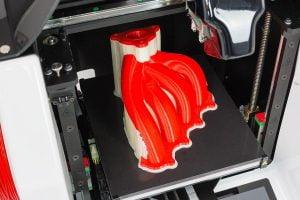

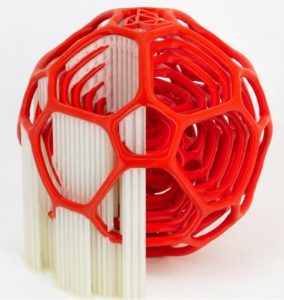

Designed to create accurate parts with great detail using soluble support material.

Water soluble support

3D printing geometrically complex models

Remove supports from the 3D printed parts without any problems. Obtain elements with a certain mobility by rinsing filament in water.

Autocalibration

No need to calibrate the 3D printer manually

User involvement in the calibration process has been minimized as much as possible.

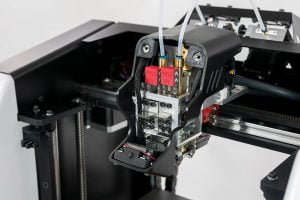

Dual swappable hotends

3D printing with multi-materials is possible.

The use of proprietary hotends guarantee high-quality parts 3D printed from model and support material.

In addition you can swapped out hotend quickly without requiring any tools.

Download the brochure