Automated Computed Tomography - Inline production CT - 100% part inspection

Inline production CT – 100% part inspection

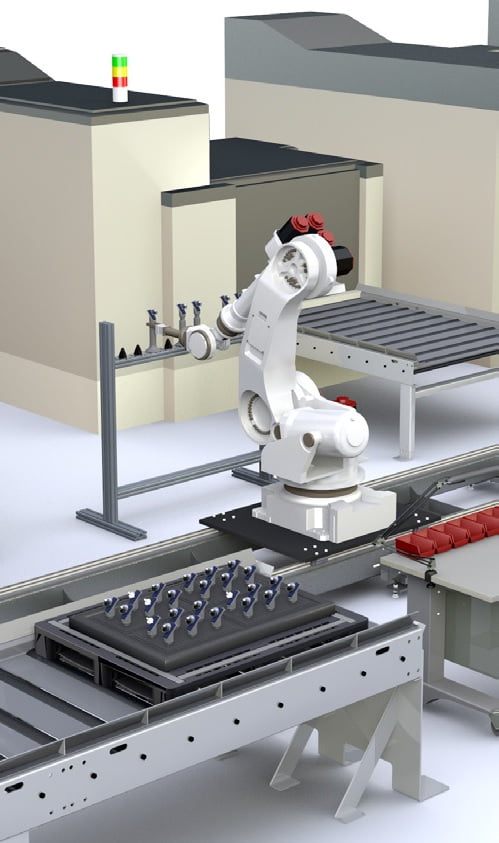

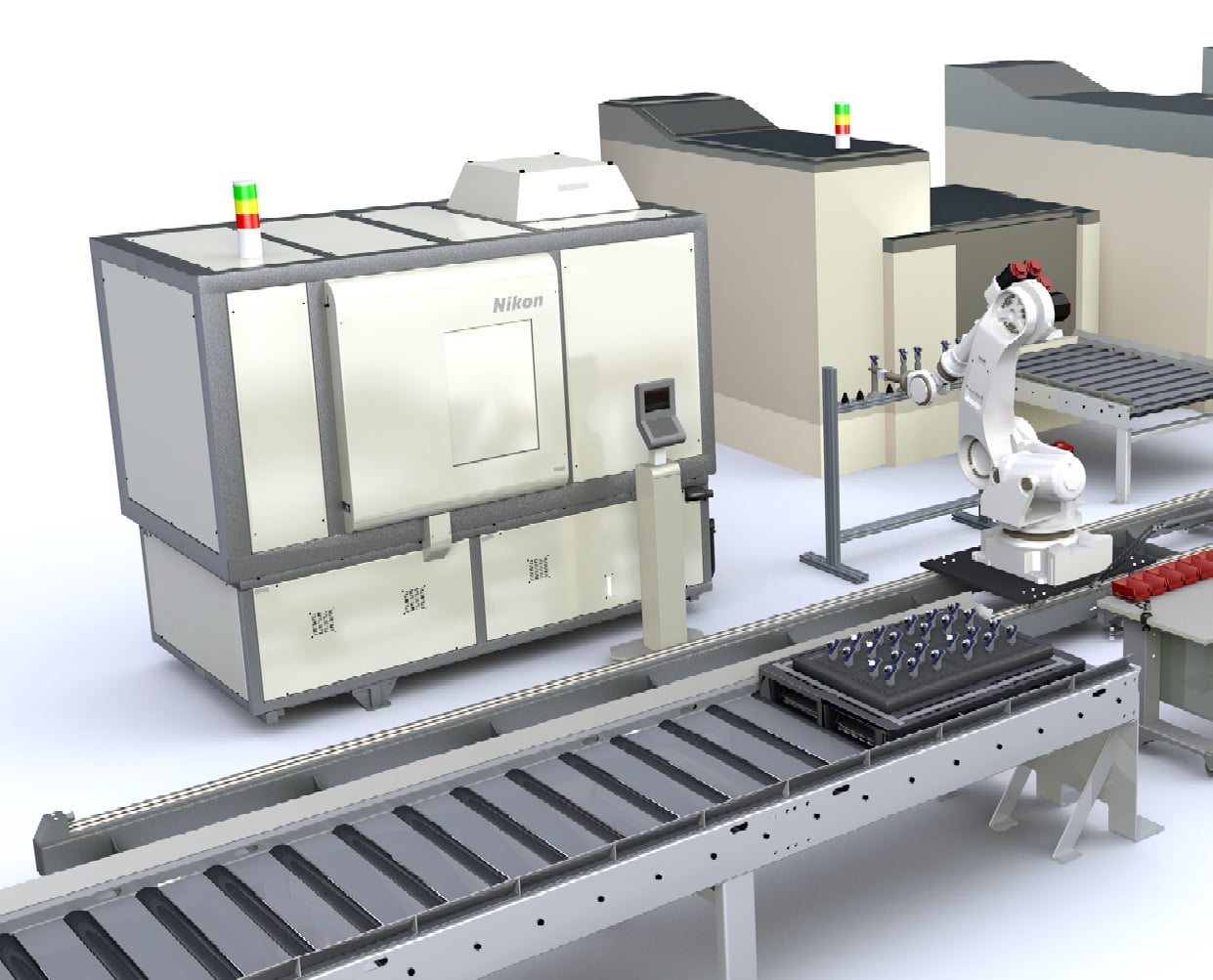

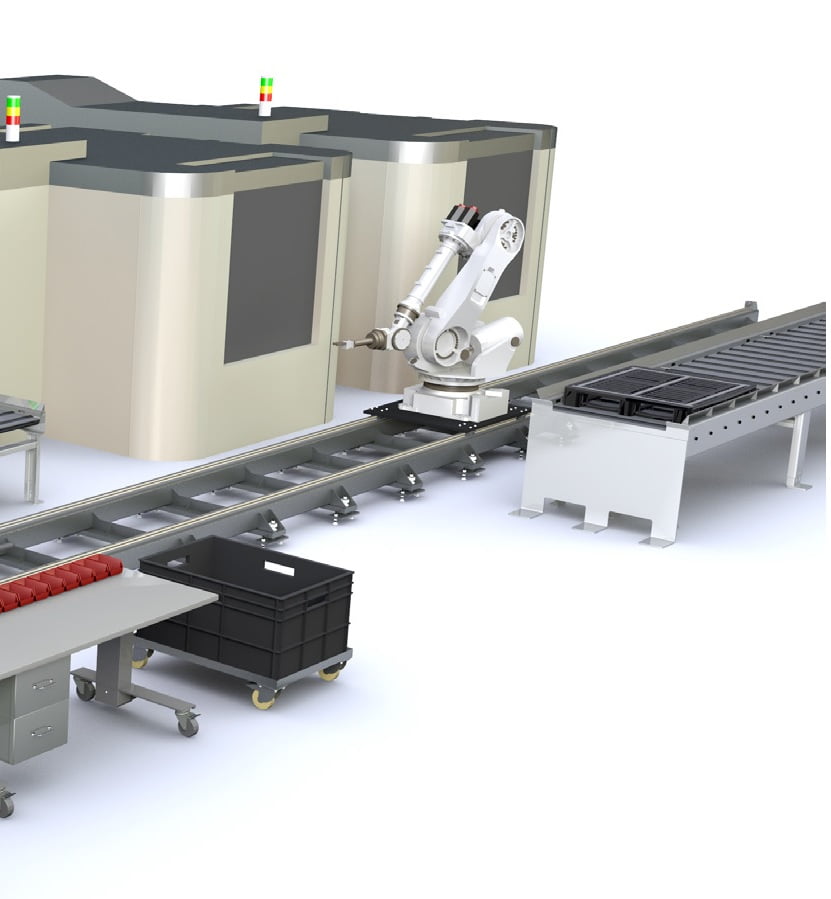

The in-line CT inspection system is a solution for fully automated production environments where critical parts with complex internal geometries or material structures need to be inspected. As such this is the ideal inspection solution for companies that implement “Industry 4.0” methodology on the shop floor.

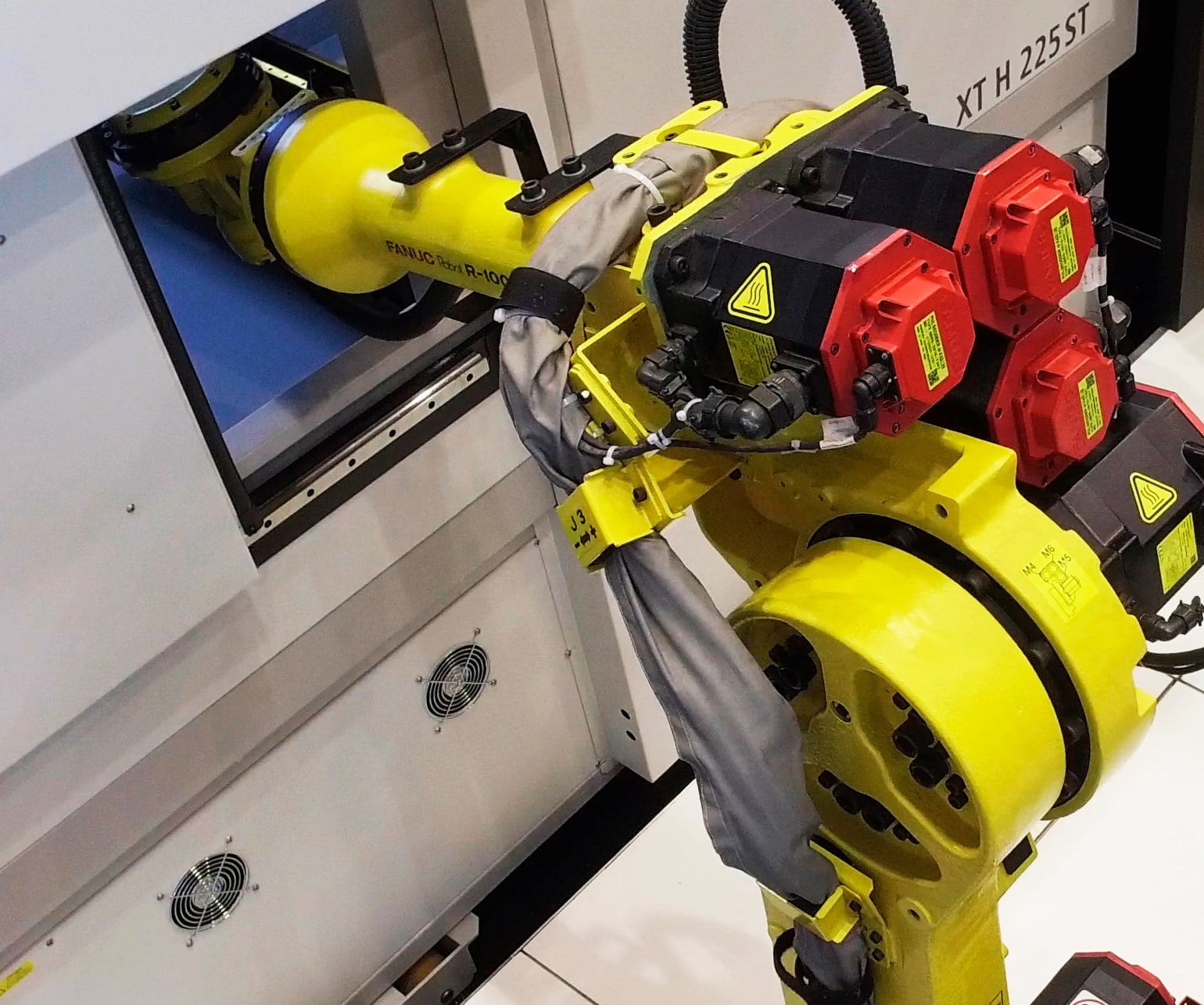

With no user input the complete CT inspection process is automated; part identification codes are scanned and handled though the database and robots load/unload from conveyors and position parts in the CT system via an automated door. The part is then automatically scanned, analyzed and sentenced according to the database recipe.

The entire process can be completed in under a minute, with possibility to scan multiple parts at once to further increase tact-time. For longer tact-times scanning and analysis of parts can occur in parallel.

Benefits

Improved quality control

- 100% inspection;

- Rapid detection and feedback of process variation;

- Eliminates operator influence on metrology;

Increased efficiency

- Control and optimize production in real-time;

- Eliminates transporting parts to and from the measurement room;

- Maintain the continuous flow of production;

Complete traceability

- Central database with all manufacturing information;

- Store inspection results for every manufactured part.

Download the brochure