Bilz Shrink Fit Adapter for collets type ER to DIN 6499

Application

Application: collet chucks, driven tool holders, direct clamping in the machine spindle

Machine type: Reversible drilling and tapping machines | Boom, Swivel, Radial Drilling Machines | Special, Turning, NC machines

Features

- Highest possible run-out and repeatability accuracy

- Increase in service life of cutting tools up to 300%

- The TER shrink fit collet can be heated on all ThermoGrip® induction units

Advantages

- A very high transmittable torque, best possible run-out properties and highest possible stability

- Better surface finishes & improved accuracy

- Maximum holding forces

- low-wear monoblock properties

- the potential of machining with much higher cutting speed

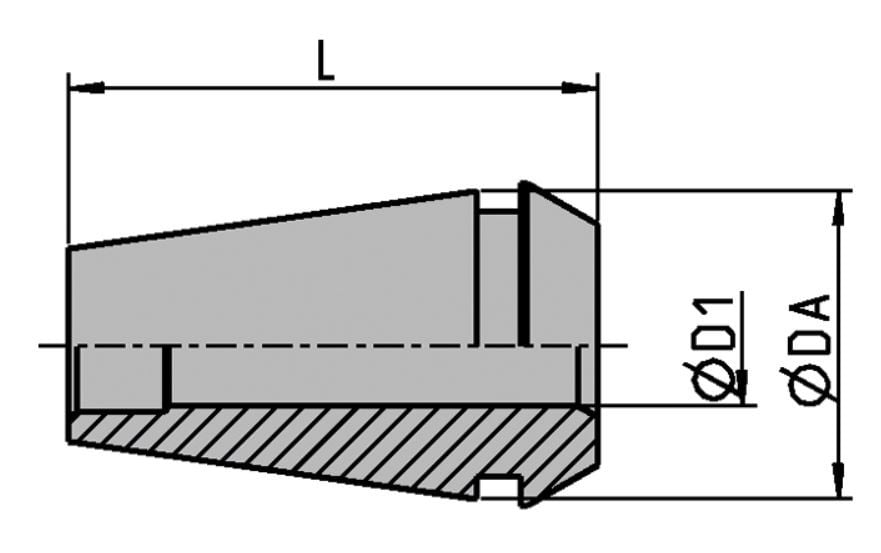

Shrink Fit Adapter for collets

type ER to DIN 6499

Application

Application: collet chucks, driven tool holders, direct clamping in the machine spindle

Machine type: Reversible drilling and tapping machines | Boom, Swivel, Radial Drilling Machines | Special, Turning, NC machines

Features

- Highest possible run-out and repeatability accuracy

- Increase in service life of cutting tools up to 300%

- The TER shrink fit collet can be heated on all ThermoGrip® induction units

Advantages

- A very high transmittable torque, best possible run-out properties and highest possible stability

- Better surface finishes & improved accuracy

- Maximum holding forces

- low-wear monoblock properties

- the potential of machining with much higher cutting speed

Description / Qualities

If the tool is not clamped securely, high forces are exerted on the tool and chuck through rotation. The tool will begin to wobble. The result: a higher load, therefore increased wear on the chuck and tool, leading to impaired quality of the manufacturing result. Using TER means that the load on the tool due to imbalance is practically eliminated.

The tool is clamped precisely in the centre of the clamping bore, meaning that it runs true and when shrunk in, it forms a stable unit with the TER collet. The short and rigid clamping enables high precision at higher cutting speeds and reduces the wear on the cutting tool dramatically.

Increase of tool life for cutting tools up to 300 %

Due to the precise clamping of the tool with the TER shrink collets, all cutters enter the workpiece simultaneously, avoiding “hitting” the cutting edge.

Result: Better surface finishes & improved accuracy

Highest possible run-out and repeatability accuracy

When shrunk in, cutting tool and shrink fit collet form a unit (monoblock)

Result: A very high transmittable torque, best possible run-out properties and highest possible stability