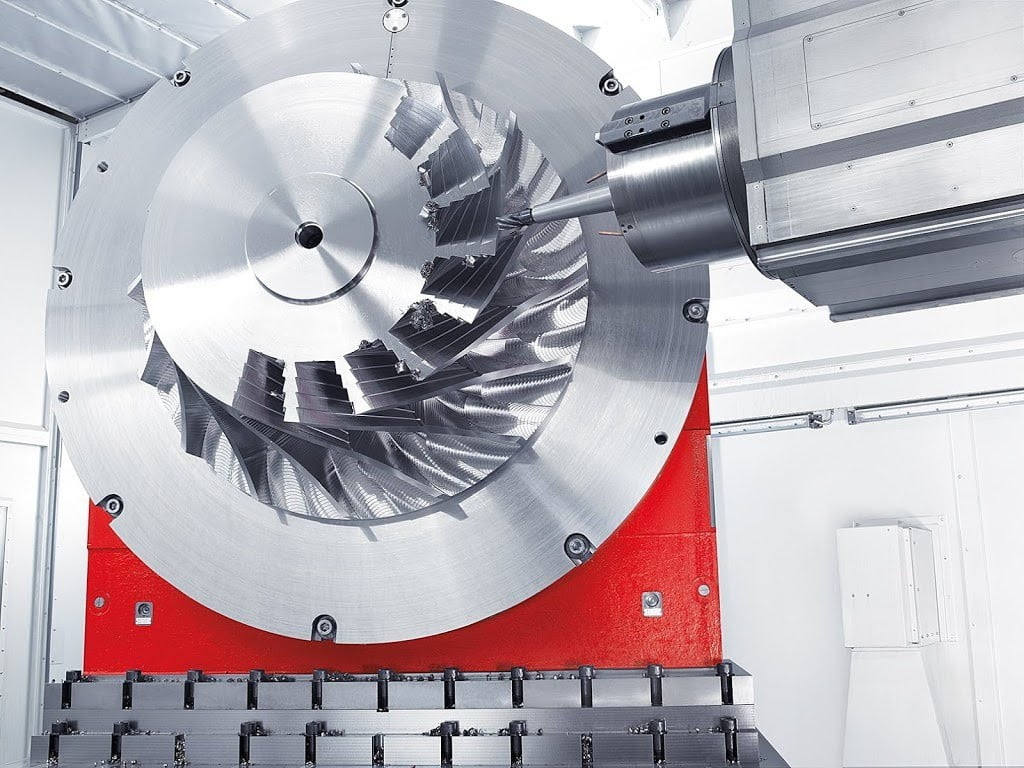

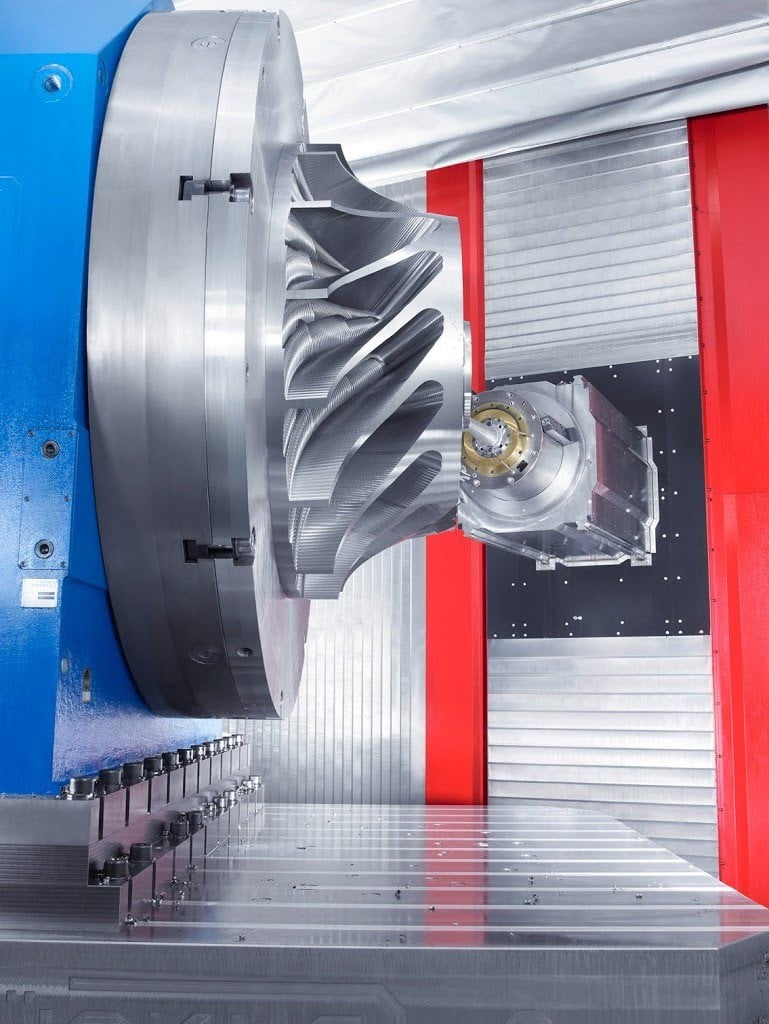

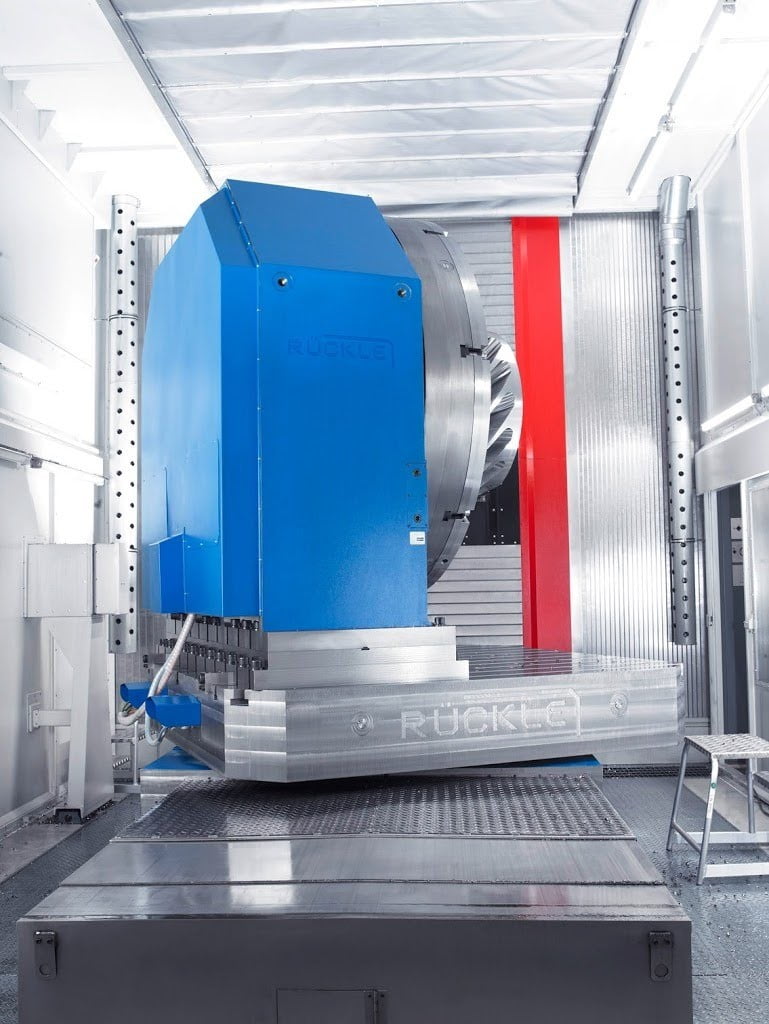

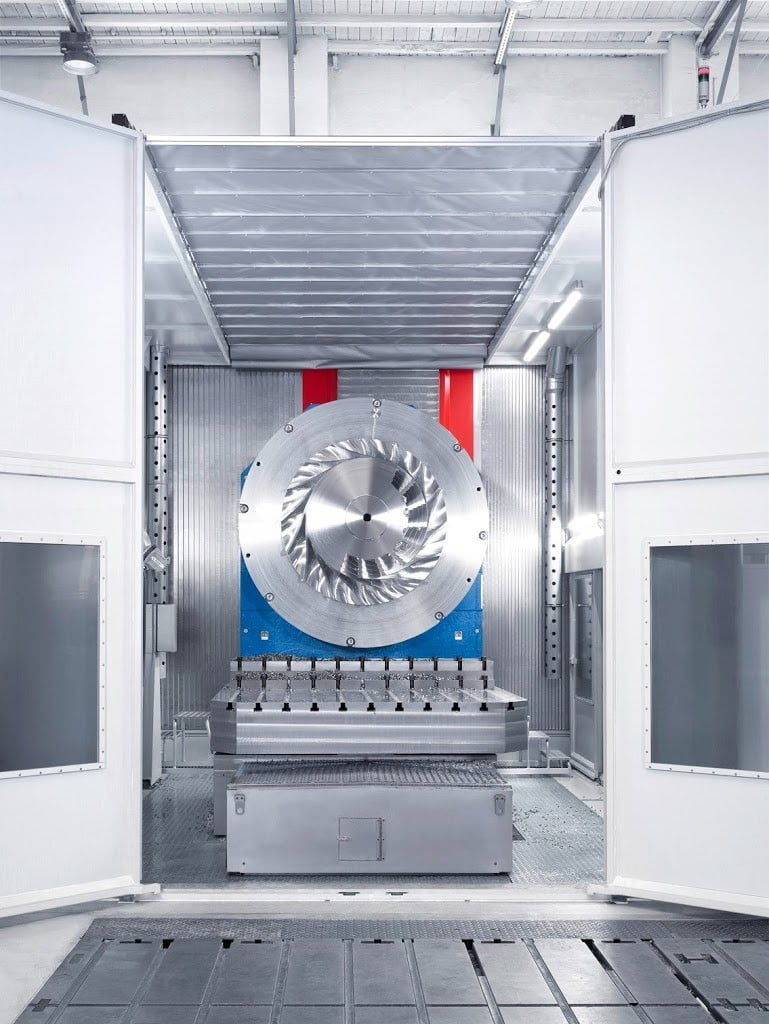

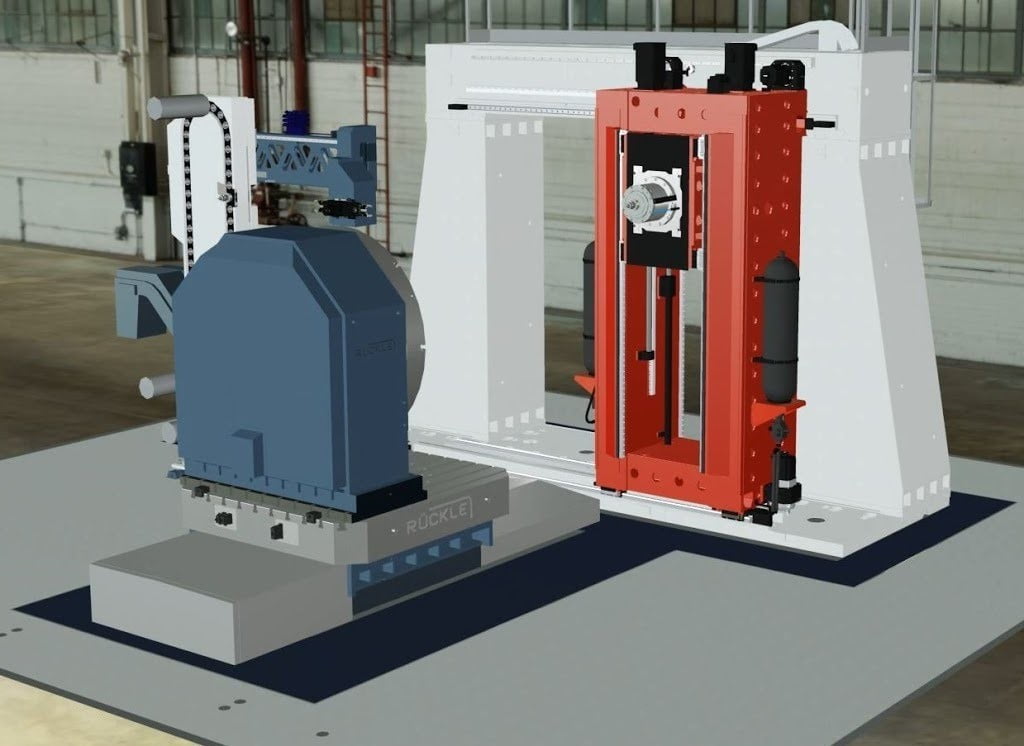

4 axis Horizontal milling machine - Trimill HC1612

- Heavy duty 4-axes machine, especially developed for the pressing tools,

injection moulds and forging dies - Machining in 4 axes by means of a rotary table

- Unique closed design of the cross-beam and cross-slide (box-in-box

design) with internal, quadruple-guided, ram-type milling unit - Upright gantry configuration machine for high dynamics and accuracy

- Constantly perfect cutting results thanks to unique thermo-symmetric design

- Stationary work piece for the highest surface qualities

- High productivity – roughing and finishing operations in one set-up

- Exceptional chip removal, especially for deep cavity cutting

- Ergonomic configuration – floor-level access to the machine tool interior

- Superior cost-performance ratio

Technical data

| Travels | |

|---|---|

| X-axis [mm] | 1.600 |

| Y-axis [mm] | 1.200 |

| Z-axis [mm] | 800 |

| Rotary table [°] | n x 360 |

| Optional spindle / head | |

| Power (S1/100%) [kW] | 25 |

| Power (S6/40%) [kW] | 33 |

| Torque (S1/100%) [Nm] | 200 |

| Torque (S6/100%) [Nm] | 264 |

| Speed [rpm] | 12.000 |

| Tool adoption | HSK – A100 |

| Optional spindle / head | |

| Power (S1/100%) [kW] | 32 |

| Power (S6/40%) [kW] | 40 |

| Torque (S1/100%) [Nm] | 306 |

| Torque (S6/100%) [Nm] | 390 |

| Speed [rpm] | 14.000 |

| Tool holder | HSK – A100 |

| Optional spindle / head | |

| Power (S1/100%) [kW] | 29 |

| Power (S6/40%) [kW] | 38 |

| Torque (S1/100%) [Nm] | 69 |

| Torque (S6/100%) [Nm] | 91 |

| Speed [rpm] | 24.000 |

| Tool holder | HSK – A63 |

| Clamping surface [mm] | 1.600 x 1.600 |

| Workpiece weight [kg] | 25.000 |

| Feed rate [mm/min] | 30.000 |

| Acceleration [m/s2] | 2,5 |

| Weight of machine [kg] |