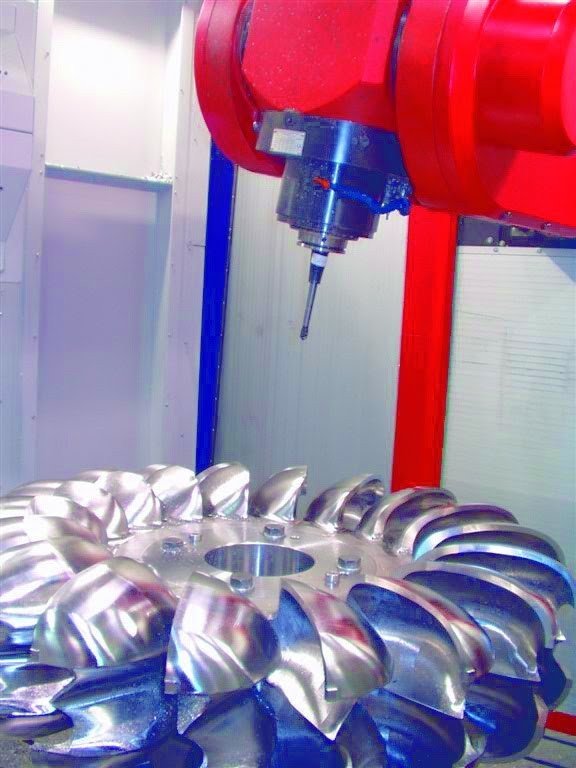

7 axis Horizontal milling machine - Trimill HF1612

- Rigid 7-axes machine, especially developed for the pressing tools, injection moulds and forging dies

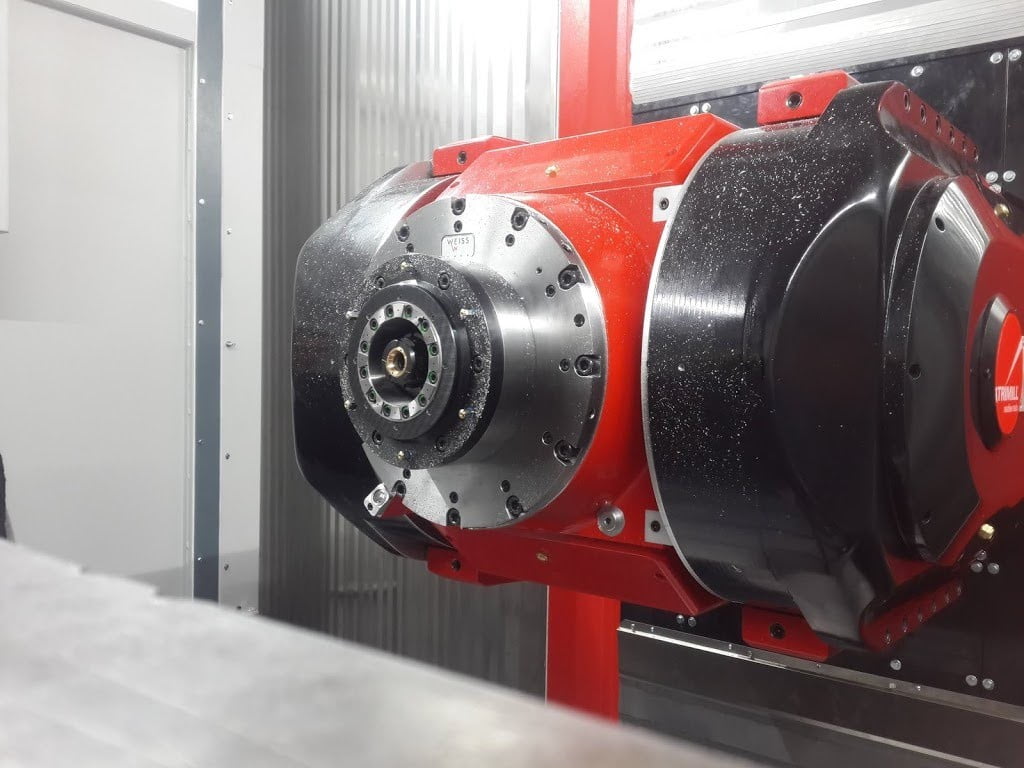

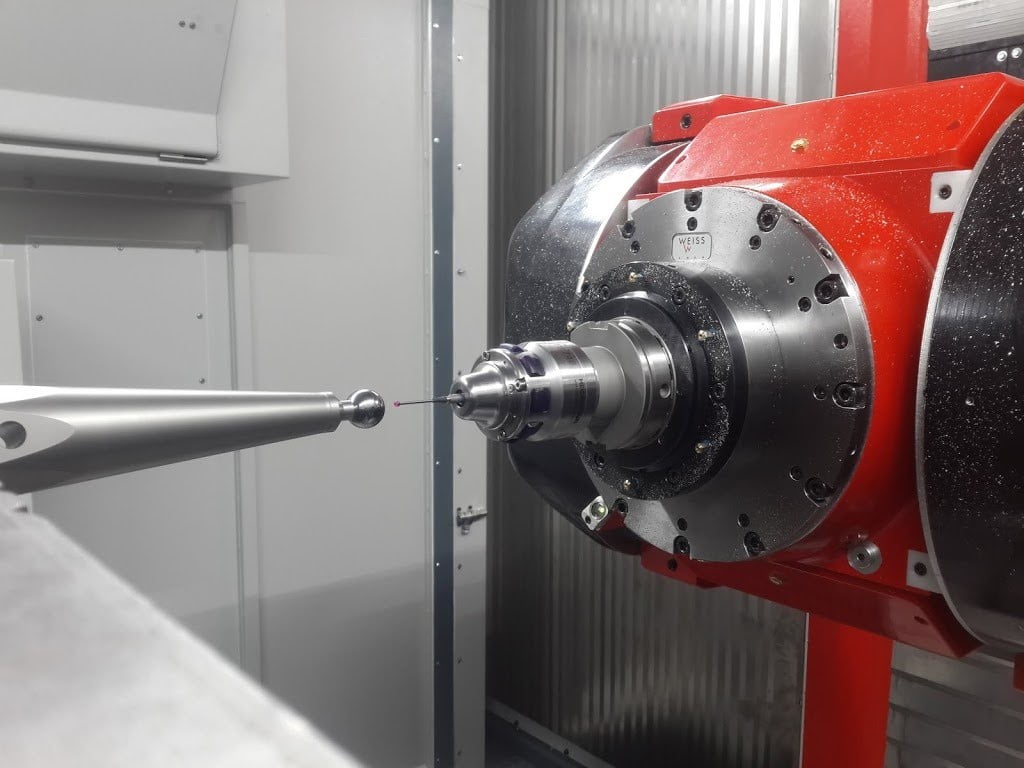

- Unique closed design of the cross-beam (X-axis) and cross-slide (box-in-box design) with internal, quadruple-guided, ram-type milling unit and milling head (Y- and Z-axis)

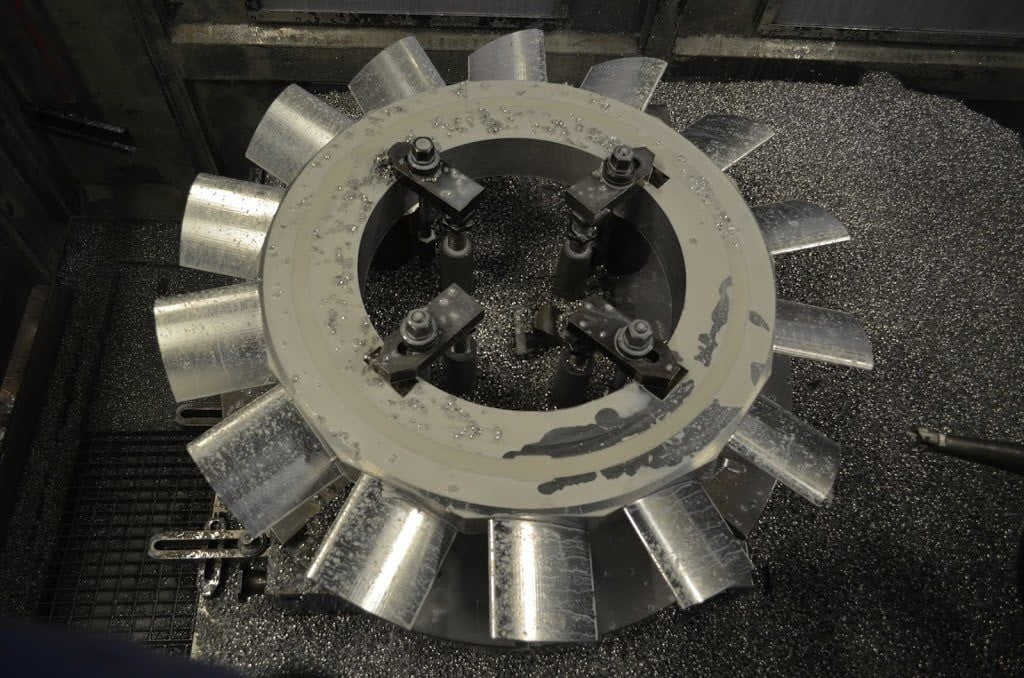

- 5-side machining by means of a rotary table and a fork-type milling head

- Upright gantry configuration machine for high dynamics and accuracy

- Constantly perfect cutting results thanks to balanced thermo-symmetric design

- Stationary work piece for the highest surface qualities

- High productivity – roughing and finishing operations in one set-up

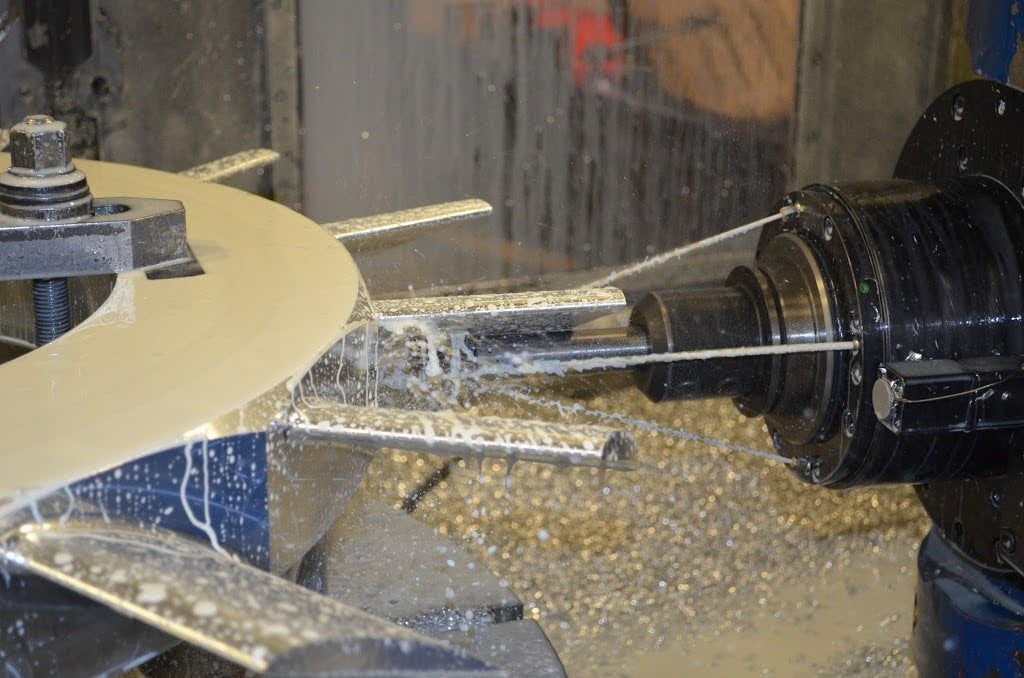

- Exceptional chip removal, especially for deep cavity cutting

- Ergonomic configuration – floor-level access to the machine tool interior

- Superior cost-performance ratio

Technical data

| Travels | |

|---|---|

| X-axis [mm] | 1.600 |

| Y-axis [mm] | 1.200 |

| Z-axis [mm] | 800 |

| Rotary table [°] | n x 360 |

| Table movement [mm] | 1.500 |

| Optional spindle / head | |

| Type | F2F |

| Power (S1/100%) [kW] | 25 |

| Power (S6/40%) [kW] | 32 |

| Torque (S1/100%) [Nm] | 194 |

| Torque (S6/100%) [Nm] | 239 |

| Speed [rpm] | 10.000 |

| Tool adoption | HSK – A100 |

| Swivel axis [°] | -2/+92 |

| Rotary axis [°] | -240/+240 |

| Clamping torque (swivel axis) [Nm] | 17.200 |

| Clamping torque (rotary axis) [Nm] | 15.000 |

| Indexing increment [°] | 0,001 |

| Optional spindle / head | |

| Type | T30C |

| Power (S1/100%) [kW] | 40 |

| Power (S6/40%) [kW] | 50 |

| Torque (S1/100%) [Nm] | 248 |

| Torque (S6/100%) [Nm] | 314 |

| Speed [rpm] | 12.000 |

| Tool holder | HSK – A100 |

| Swivel axis [°] | -100/+100 |

| Rotary axis [°] | -240/+240 |

| Clamping torque (swivel axis) [Nm] | 8.000 |

| Clamping torque (rotary axis) [Nm] | 8.000 |

| Indexing increment [°] | continuous |

| Optional spindle / head | |

| Type | T30C CSC |

| Power (S1/100%) [kW] | 50 |

| Power (S6/40%) [kW] | 62 |

| Torque (S1/100%) [Nm] | 251 |

| Torque (S6/100%) [Nm] | 313 |

| Speed [rpm] | 20.000 |

| Tool holder | HSK – A100 |

| Swivel axis [°] | -100/+100 |

| Rotary axis [°] | -240/+240 |

| Clamping torque (swivel axis) [Nm] | 8.000 |

| Clamping torque (rotary axis) [Nm] | 8.000 |

| Indexing increment [°] | continuous |

| Optional spindle / head | |

| Type | T21C |

| Power (S1/100%) [kW] | 42 |

| Power (S6/40%) [kW] | 50 |

| Torque (S1/100%) [Nm] | 67 |

| Torque (S6/100%) [Nm] | 84 |

| Speed [rpm] | 24.000 |

| Tool holder | HSK – A63 |

| Swivel axis [°] | -100/+100 |

| Rotary axis [°] | -240/+240 |

| Clamping torque (swivel axis) [Nm] | 4.000 |

| Clamping torque (rotary axis) [Nm] | 4.000 |

| Indexing increment [°] | continuous |

| Optional spindle / head | |

| Type | T21C CSC |

| Power (S1/100%) [kW] | 29 |

| Power (S6/40%) [kW] | 38 |

| Torque (S1/100%) [Nm] | 69 |

| Torque (S6/100%) [Nm] | 91 |

| Speed [rpm] | 24.000 |

| Tool holder | HSK – A63 |

| Swivel axis [°] | -100/+100 |

| Rotary axis [°] | -240/+240 |

| Clamping torque (swivel axis) [Nm] | 4.000 |

| Clamping torque (rotary axis) [Nm] | 4.000 |

| Indexing increment [°] | continuous |

| Clamping surface [mm] | 1.600 x 1.600 |

| Workpiece weight [kg] | 25.000 |

| Feed rate [mm/min] | 30.000 |

| Acceleration [m/s2] | 2,5 |

| Weight of machine [kg] |