Vertical Milling Machine 3 axis - Trimill VC4535

- Heavy duty 3-axes machine, especially developed for the tool-, die- and mould industry

- Closed design of the double-beam and cross-slide (box in box design) with internal, quadruple guided ram-type milling unit

- Constantly perfect cutting results by means of load- and thermo symmetric design

- Execution as overhead gantry, therefore controlled dynamic and accuracy

- Stationary work piece for constantly good surface qualities

- High productivity by means of roughing and finishing in one set-up

- Very compact machine, large working area in spite of extreme small floor-space

- Customized distance between spindle nose and clamping surface

- Ergonomic operation by means of floor-level access to the machine tool

- Convincing cost-performance ratio

Technical data

| Travels | |

|---|---|

| X-axis [mm] | 4.500 |

| Y-axis [mm] | 3.500 |

| Z-axis [mm] | 1.500 |

| Optional spindle / head | |

| Power (S1/100%) [kW] | 32 |

| Power (S6/40%) [kW] | 40 |

| Torque (S1/100%) [Nm] | 306 |

| Torque (S6/100%) [Nm] | 390 |

| Speed [rpm] | 14.000 |

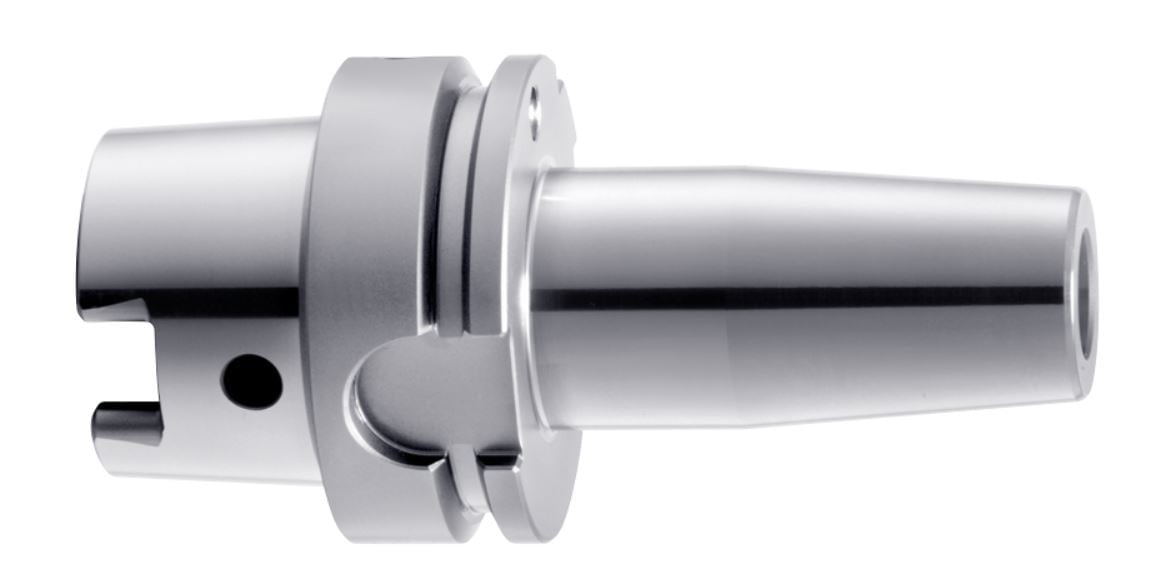

| Tool adoption | HSK – A100 |

| Optional spindle / head | |

| Power (S1/100%) [kW] | 52 |

| Power (S6/40%) [kW] | 70 |

| Torque (S1/100%) [Nm] | 1.000 |

| Torque (S6/100%) [Nm] | 1.335 |

| Speed [rpm] | 2.500 |

| Tool holder | HSK – A100 |

| Clamping surface [mm] | 5.000 x 3.800 |

| Workpiece weight [kg/m2] | 7.000 |

| Feed rate [mm/min] | 40.000 |

| Acceleration [m/s2] | 3 |

| Weight of machine [kg] |