CompactMark G8 - LASIT

The CompactMark G8 is a 3-axis positioning laser that allows precise and repeatable marking thanks to its welded and precision machined steel construction with ground guides and recirculating ball screws.

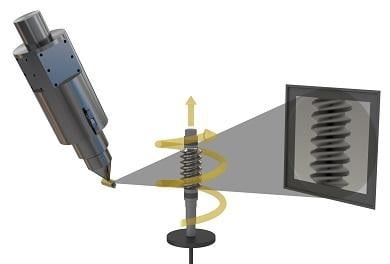

The machine makes it easy to mark large components and pallets with hundreds of parts. The system can have up to 6 axes with the option to add the tilting rotary axis and the rotating head.

The CompactMark G8 is a 3-axis positioning laser that allows precise and repeatable marking thanks to its welded and precision machined steel construction with ground guides and recirculating ball screws.

The machine makes it easy to mark large components and pallets with hundreds of parts. The system can have up to 6 axes with the option to add the tilting rotary axis and the rotating head.

The CompactMark G8 allows the marking of an area of 700x450mm (with focal length FFL160), thanks to the movement of the X-axis and the Y-axis working plane. This marker is ideal both for engraving on a single part and on a pallet with hundreds of small parts, always maintaining perfect centring.

The frame of the CompactMark G8 is completely made of stretched and machined welded steel. After thermal stress relief, the structure is finished to create support shelves for screws and slides. This allows greater acceleration of the axles without vibration, and guarantees stability and strength.