Computed Tomography Software Inspect-X: X-ray and CT acquisition and processing

Inspect-X: X-ray and CT acquisition and processing software

Inspect-X has been designed around the user experience, resulting in intuitive and productive X-ray inspection. Inspect-X features user friendly wizards to guide users through complex inspections, as well as utilizing the most advanced visualization and analysis function capabilities. XT V systems with Inspect-X enable rapid deployment of new product lines, within minutes, rather than hours or days.

Benefits

- Focused on increasing productivity for electronics X-ray inspection

- Workflow based – all necessary controls available to the user’s process

- Interactive visualization or fully automatic inspection

- Ultra sharp images for correct decision-making

- High-resolution and high-magnification imaging reveals all defects

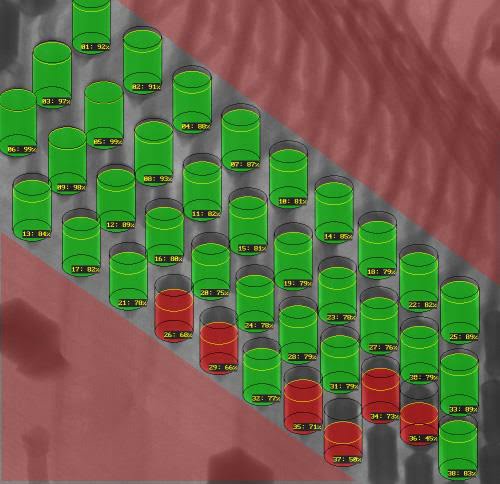

- Component specific automated pass/fail analysis for BGA, bond wires

- Automatic HTML report generation

- Integrated CT acquisition

- Minimum training time

Benefits & features

Real time X-ray inspection

- On-screen joysticks and mouse gestures, as well as conventional intuitive joystick control, for interactive live part positioning

- Variable magnification and tilted viewing angle allow real time detection of defects such as head-in-pillow

- Magnification, tilt and rotate in all positions whilst maintaining a region of interest consistently locked into the center of the field-of-view

- Clear imaging engine provides crystal-clear live images

- Real-time imager for interactive visualization

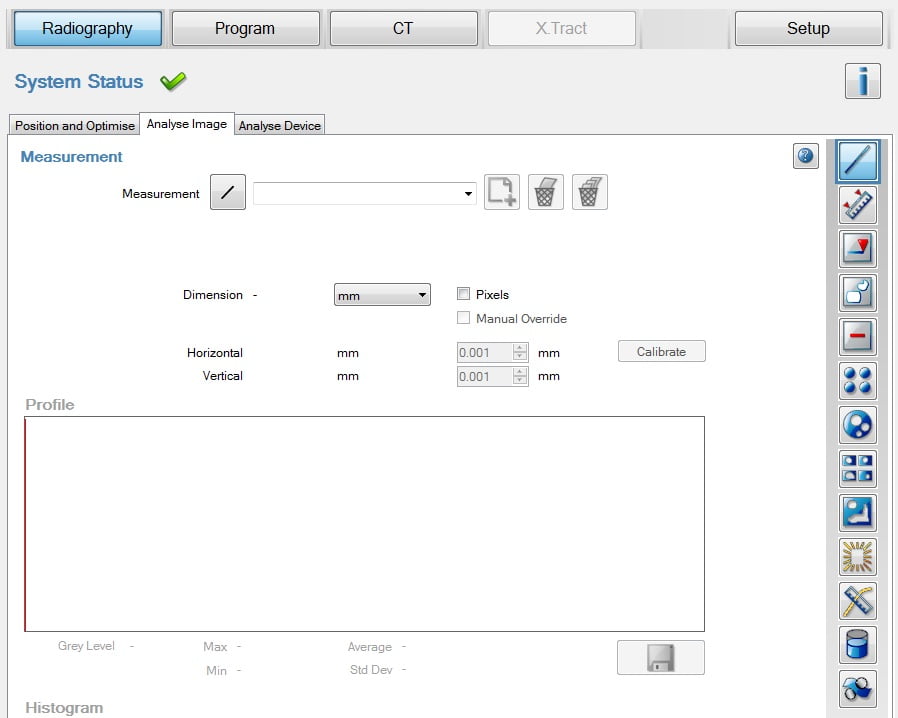

Image enhancement and analysis

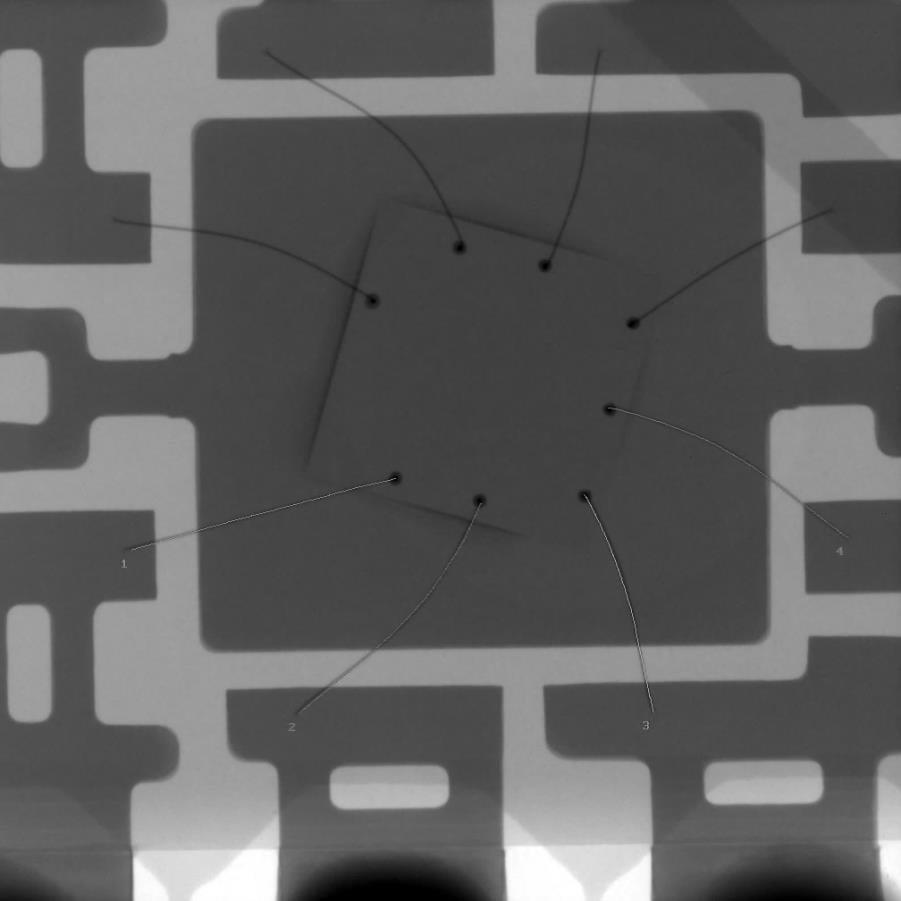

C.Clear intelligently adapts to changing X-ray conditions and sample positions, automatically adjusting image controls, contrast and brightness in order to provide the clearest and sharpest images to aid in defect recognition. Real-time enhancements and filters can be chosen and stored as user profiles to suit different sample types or individual operator preferences.

With C.Clear, operators can make fast and well-informed decisions, enabling defects to be detected correctly first time, especially for hard to detect faults within multi-tier BGA or complex bond wires. The C.Clear imaging engine enables manufacturers to increase inspection throughput and to reduce false call rates, leading to improved quality and efficiency.

- Real-time enhancements and filters stored as user profiles to suit different sample types or individual operator preferences

- Image processing filters (sharpen, smooth, edge detect, emboss, background subtract, etc.)

Insightful reporting

Inspect-X provides a suite of easy-to-use tools and customizable HTML templates for endless real-time or automated reporting possibilities. Reports can be easily shared with colleagues or suppliers to facilitate decision-making. Results are available for offline analysis and troubleshooting on validation station.

Maximize productivity

Inspect X automation

Operating in automated inspection mode, the XT V combined with Inspect-X is a productive X-ray solution for repeated inspection of PCBAs, semiconductor components and complex high density boards. Creation and execution of inspection routines is straightforward, utilizing the graphical interface or teach and learn.

- Macros for automating simple repetitive tasks

- Inspection programs for automated inspection and analysis of full boards or multiple components

- Automated inspection programs require no programming skills, utilizing graphical interface or teach and learn

- Intelligent program control (ipc) for complete customizable system control

- Off-line validation station giving maximum efficiency of the X-ray system

- HTML reporting function, readable on any pc with no special software

- Switch seamlessly between radiographic (2D) and CT (3D) modes in one single software

- Visual check during automated inspection routine allows interactive inspection

Integrated CT acquisition

Users requiring detailed insight of (multi-layer) electronic components can benefit from the optional Computed Tomography functionality for a full 3D view of internal structure.

- CT acquisition and analysis as factory option or field upgrade

- Easy, user guided, CT data collection

- Fast rescan – rescan in only two steps

- World-leading reconstruction times

- Automatic reconstruction of CT data streamed from XT V system

- Powerful CT analysis in the software of your choice