Robotic Residual Stress X-Ray Diffractometer – GNR StressX

Robotic Residual Stress X-Ray Diffractometer

Non-destructive analysis on any dimensions samples

* EN UNI 15305 and ASTM 915 compliant

* X Ray Diffractometer mounted on 6-axis robot

StressX is a X-Ray Diffractometer dedicated to the Residual Stress Analysis, providing a non-destructuve test of the samples. The head of the diffratometer is mounted on an anthropomorphic 6 axis robot that allows to analyze samples of any dimensions and shapes.

StressX could be mounted either in a closed cabin, suitable for laboratory analysis or on a four wheel trolley for on site analysis.

Residual Stress could be induced by machining, grinding, rolling, deep drawing, welding, thermal hardening and shot peening; its quantification allows to prevent fatigue damage and to control material’s durability and safety.

StressX provides a flexible solution to residual stress determination on samples of any dimensions by the original synergy between compact X ray diffractometer and 6-axis robot.

6-axis robots are available with positioning accuracy and repeatability as low as 20 μm and positioning range as high as 895 mm radius from robot center.

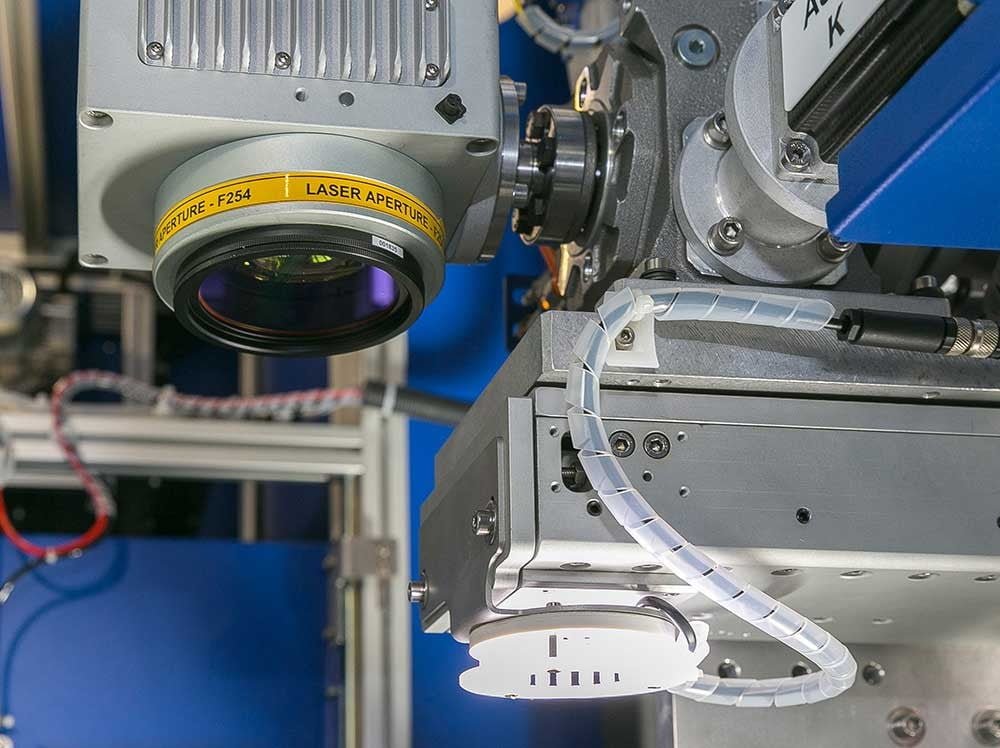

Measuring target is defined by a combination of a Video camera for X-Y pointing and a laser for Z positioning.

Laser accuracy can be less than 10 μm and measuring range can be as high as 300 mm from the goniometer center.

Thanks to the 6 degree of freedom the measuring positions and angular ranges are only limited by robot size.

Applications:

Some specific applications of the Stress-X are listed below:

- Detection of Residual Stress on sprocket wheels

- Detection of Residual Stress on car motor parts (cam axles, connecting rods, engine shafts, equalisers, …)

- Detection of Residual Stress induced by deep drawing (household appliances, structural parts, …)

- Detection of existing Operational Stress on gas conducts

- Detection of Operational Stress on large tensioned structures

- Measurement of efficiency of Shot-Peening and rolling of components subjected to Stress

- Definition of the quantity of Retained Austenite on bearings and parts of diesel motor injectors

- Detection of Residual Stress in castings (cast iron parts of tool machines and aluminium components)

- Detection of Stress induced by welding (laser and electron)

- Search for a correlation between residual stress and stress resistance of aluminium alloy car rims

- Optimisation of working parameters for swarf removal to improve the stress resistance of mechanical components

- Detection of Residual Stress on helicoidal and leaf springs

- Search for critical zones after applying work loads (arms and aeronautics)

Software:

Acquisition and Stress Analysis

A specific Software allows to measure and calculate residual stress on any polycristalline material.

- Acquisition time/step : 30-120 s

- Step : 5-13

- Peak position determination by profile fitting taking into account theoretical constrains

- Uni-axial, bi-axial and tri-axial stress State analysis

- Normal and shear component analysis available for uni-axial measurements

Download the brochure