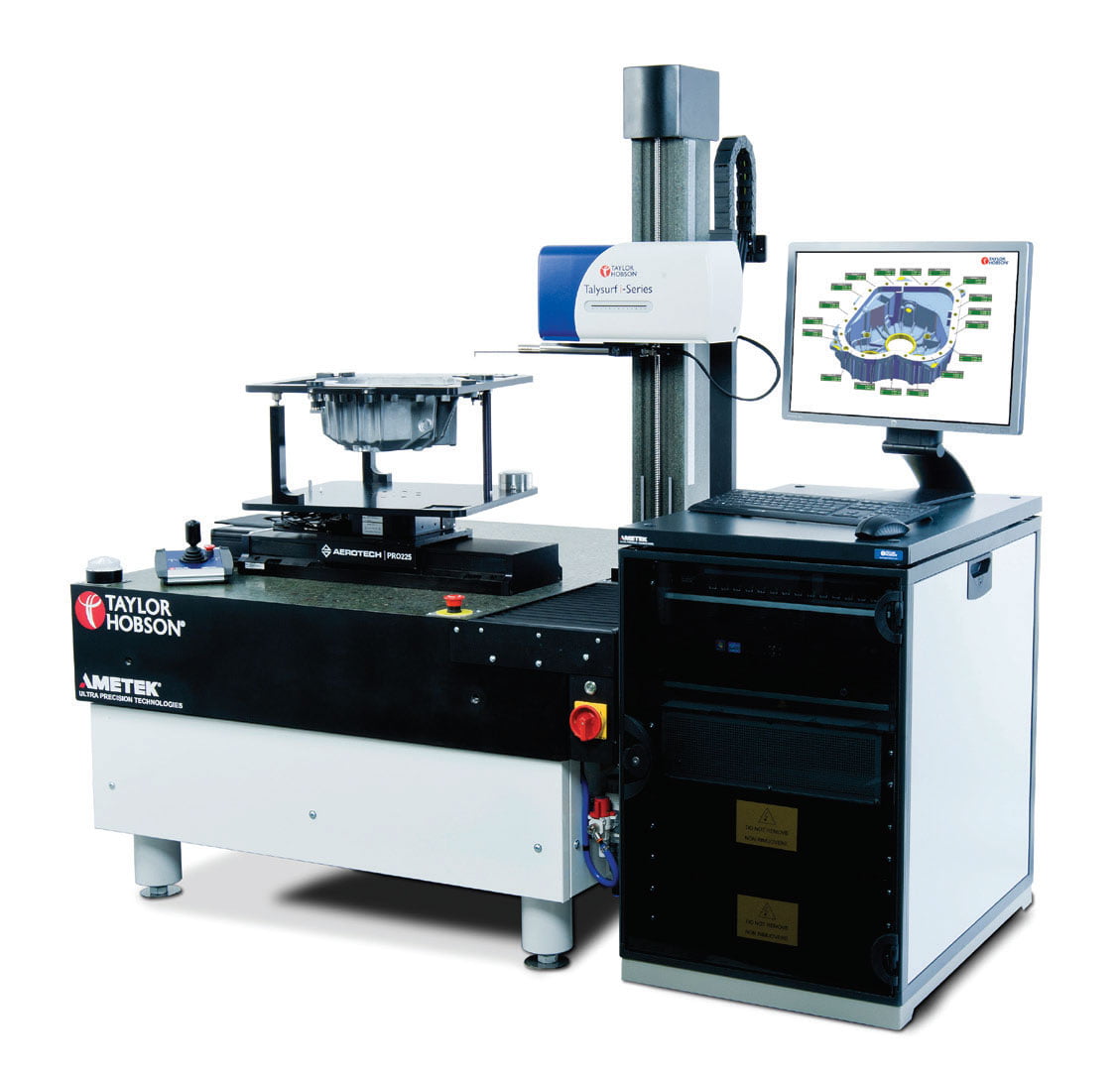

Form Talysurf® CNC Series - Taylor Hobson

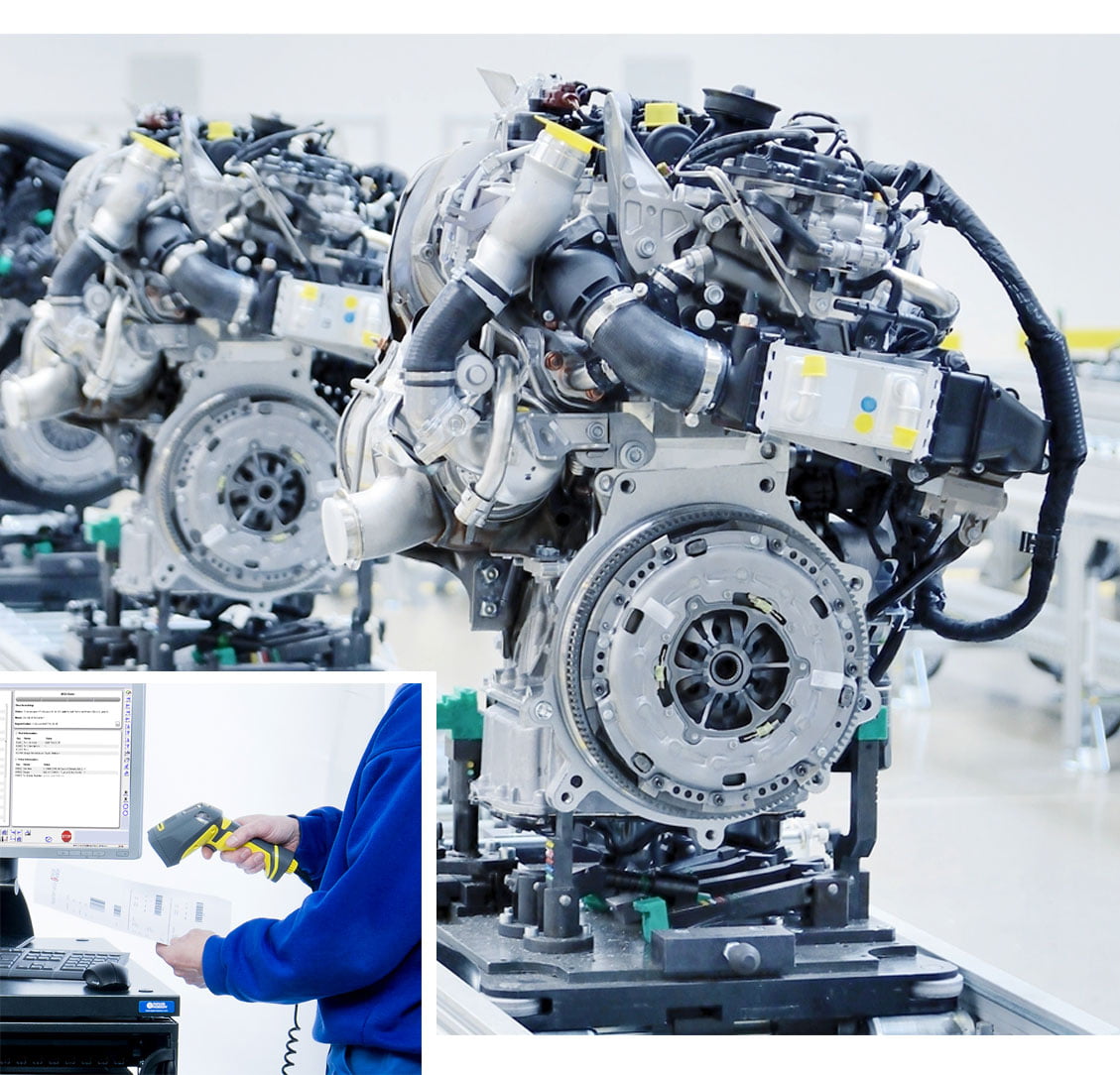

Form Talysurf CNC Series is a versatile, high range, high resolution, automated surface finish, form and contour measurement instrument. While the use of highly automated manufacturing systems in automotive production is well established, quality control has remained a manual process. The arrival of the Form Talysurf CNC Series for automated quality control will change that.

The system can be programmed to your individual requirements for analysis of crankshafts, heads, blocks, gear box casings and much more.

The Form Talysurf CNC Series is supplied with Taylor Hobson’s Q-Link production interface, software that meets the Industry 4.0 philosophy. Q-Link is designed for shop floor environments and provides direct communication with SPC software which delivers feedback to your manufacturing process.

Form Talysurf CNC Series System Benefits and Features:

- Cycle times are greatly reduced – Up to 8 axes of motion

- High accuracy gauge

- Temperature compensation

- Fully automated measurement

- Simple user friendly interface

- Customizable fixtures and work holdings

- Robust measurement solution – Suitable for all environments.

Download the brochure