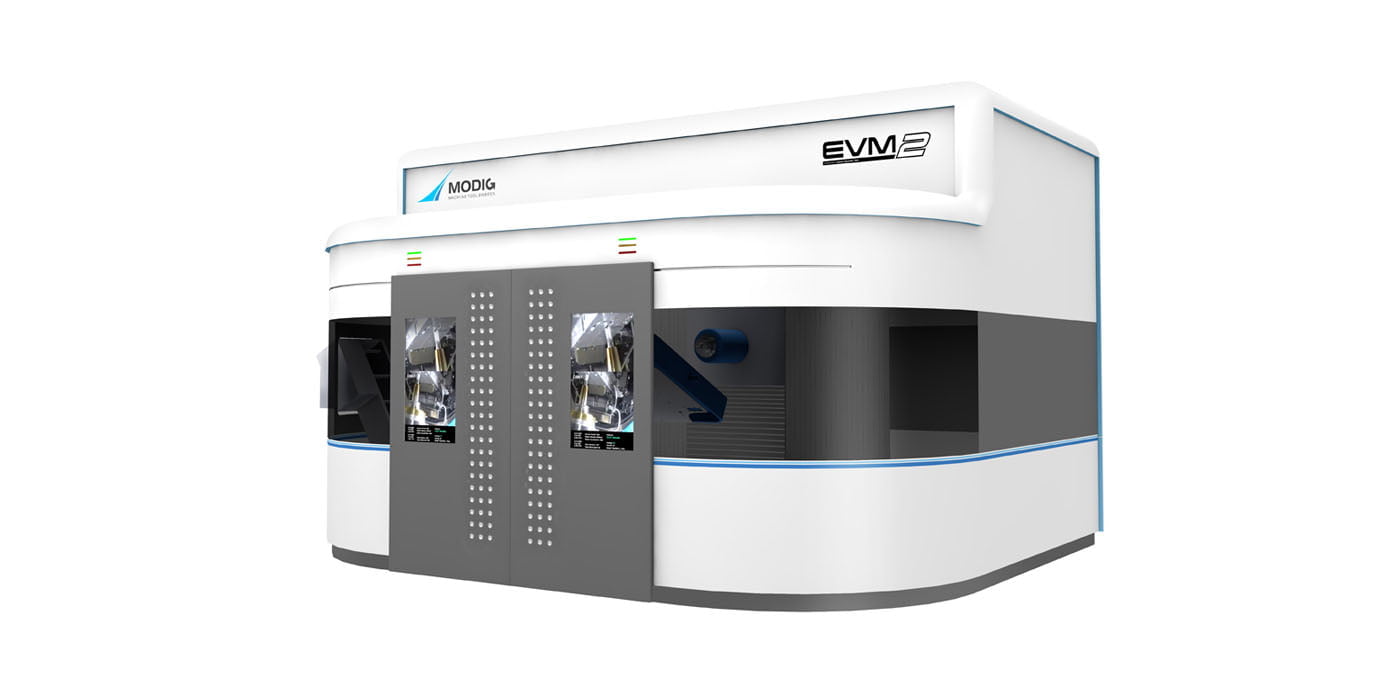

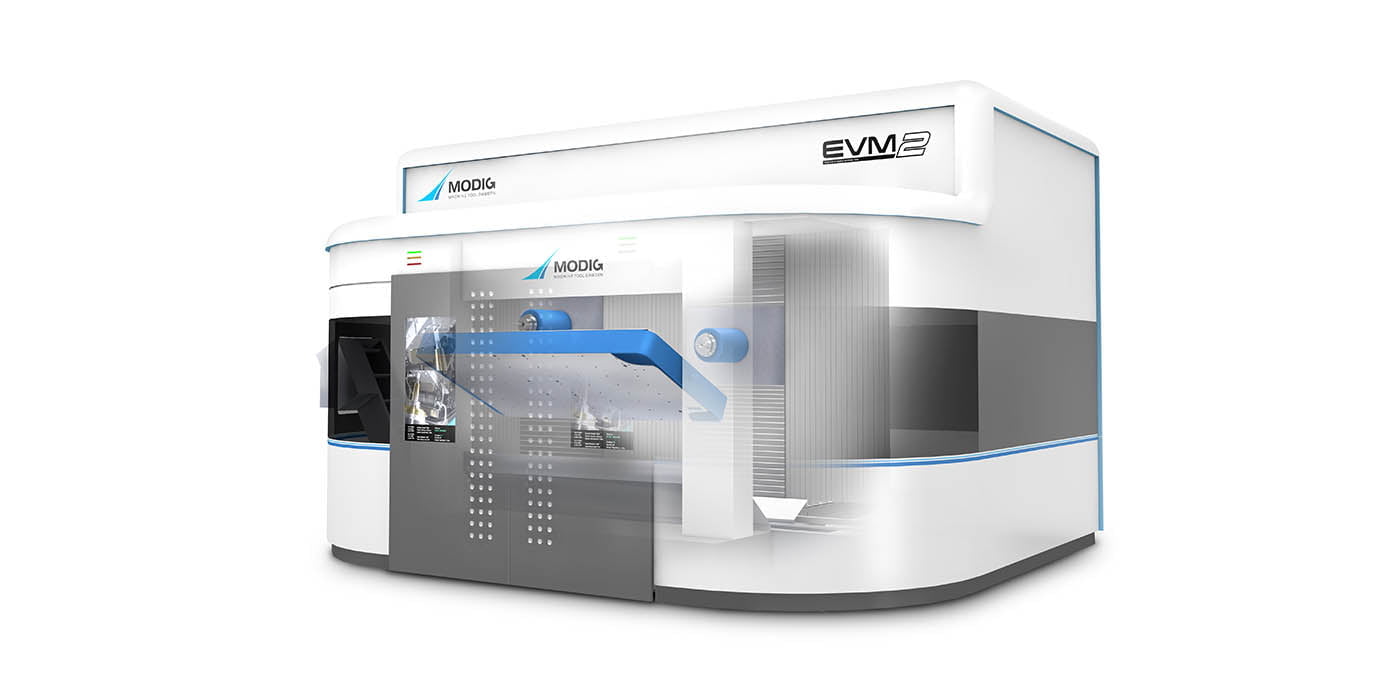

Horizontal 4 axis machining center MODIG EVM-2

Especially developed for battery trays and frames of electric vehicles. This single set-up, twin-spindle machine (options for four-spindles) substantially reduces traditional cycle times, increases efficiency, minimizes production cost, and achieves maximum productivity.

The EVM-2 has a 95% uptime guarantee and a minimum of 40% cycle time reduction compared to current processes. A working envelope of 63″ x 138″ (1,600 mm x 3,500 mm) makes it ideal for parts like battery trays, longitudinal beams, frames, cross beams, and profile parts.

MODIG provide solutions to make your production more efficient. Your machining cycle time at the process design stage: up to 50% faster machining time over conventional processes, better than 95% machine uptime, and true Lean and Green production.