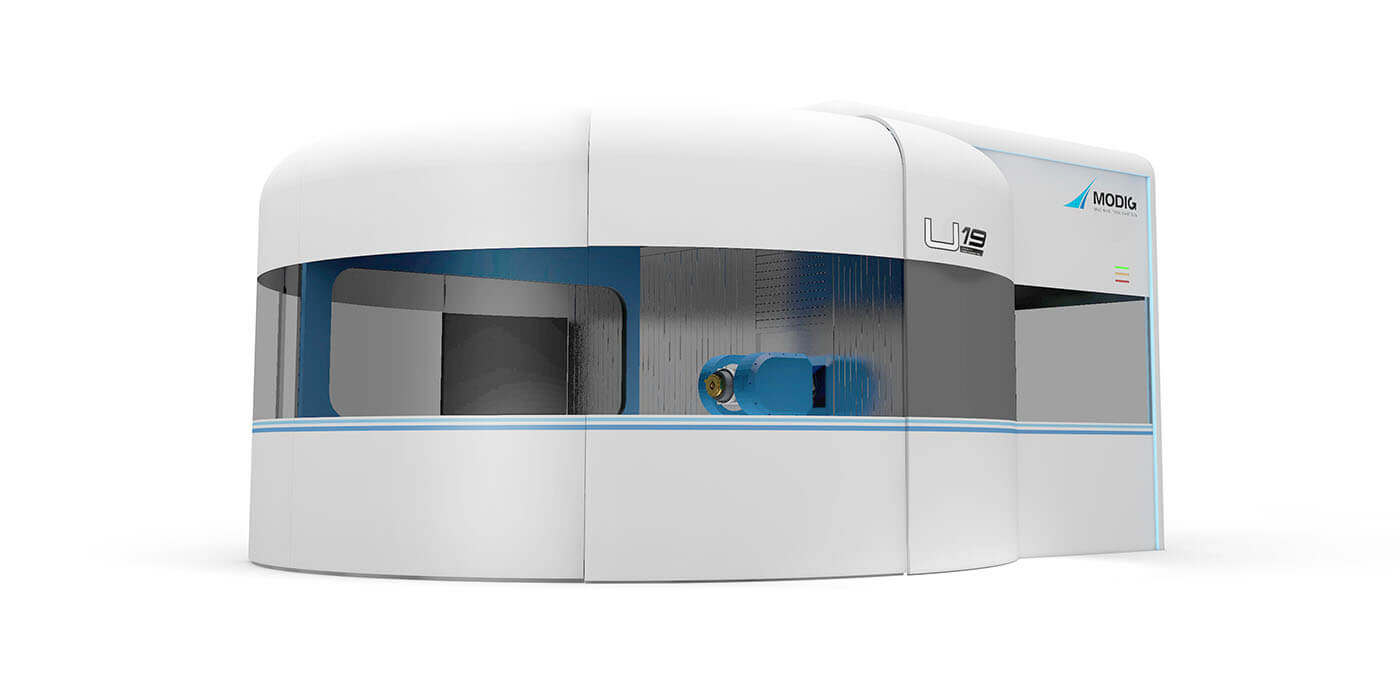

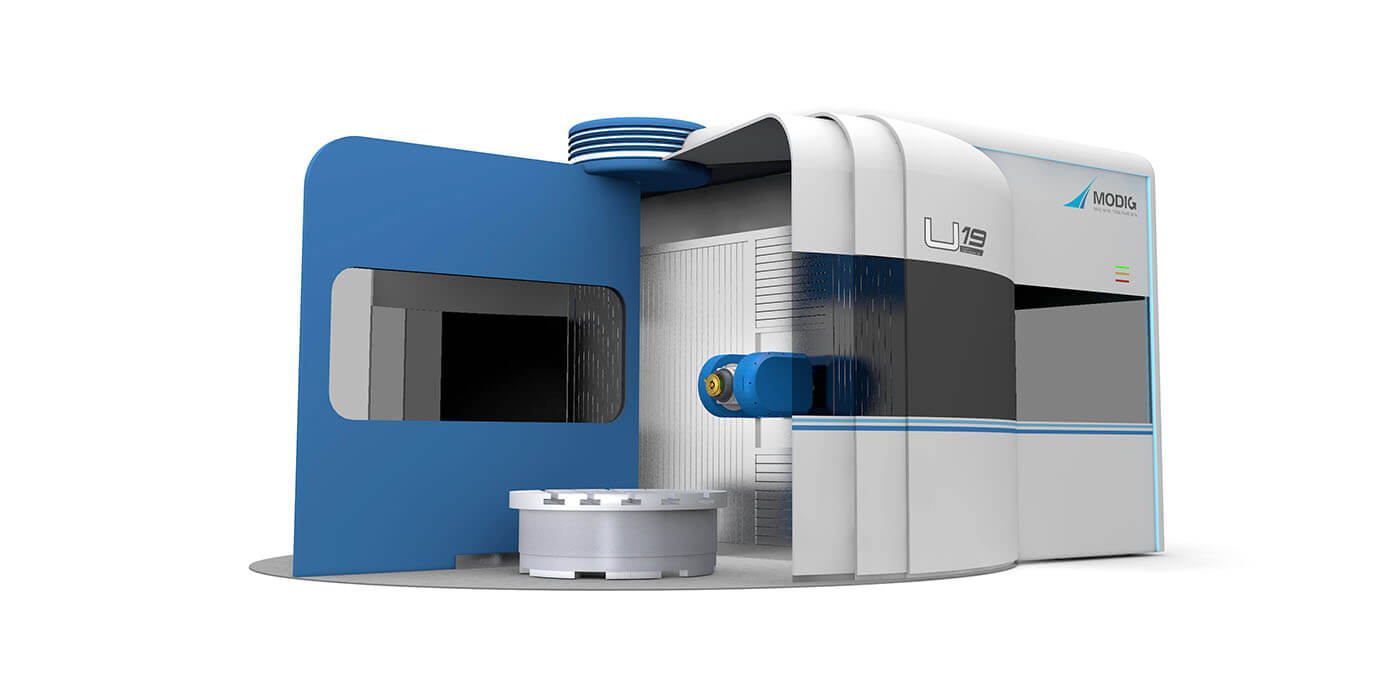

The versatility of this machine makes it easy for our customers to configure it for their specfic needs. Dual rotary tables or automated pallet systems provide manufacturers with increased production flexibility, efficiency and the capability to accommodate a variety of products. Its “no Ram” feature allows extreme accuracies and high surface quality.

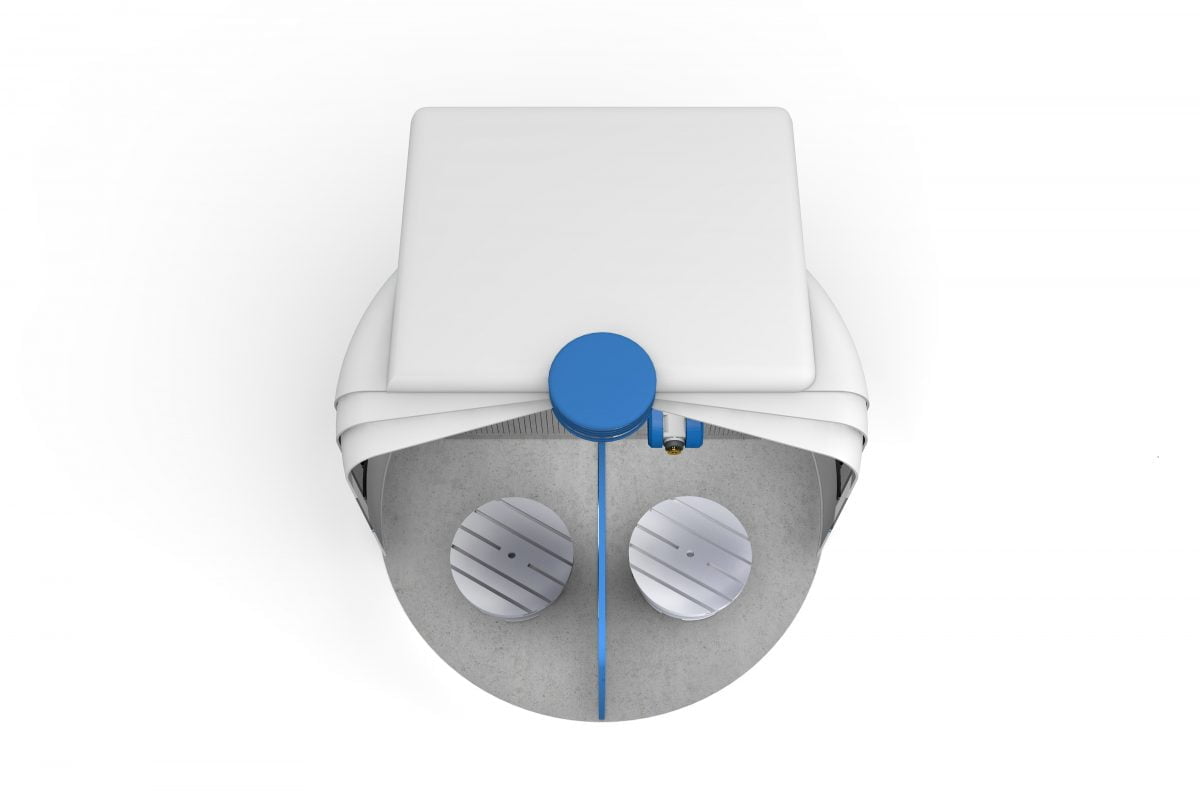

The Modig rotary tables, which can be installed in dual zones with a tool changer in between, can be equipped with four indexing positions or with continuous C-axis.

Depending on requirement, the U19 will be equipped with either 4th axis spindle or 5th axis spindle and a 6th axis from the rotary table.