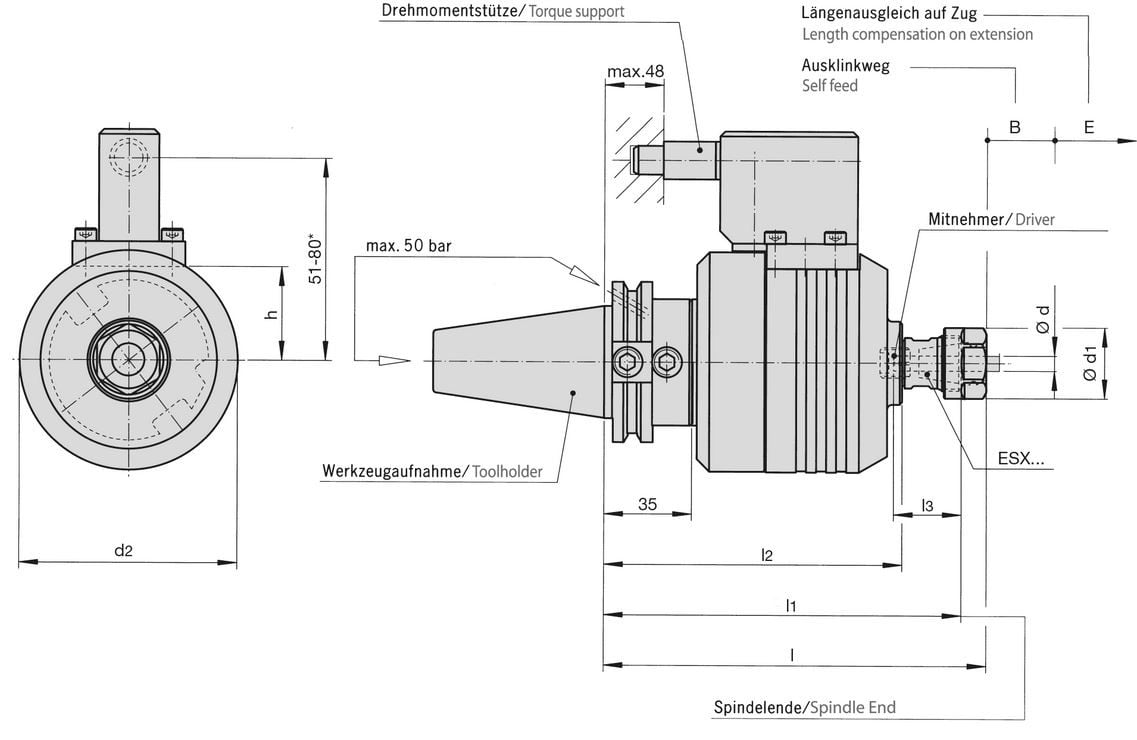

ilz Self Reversing Tapping Attachment GNCK High performance tapping attachments with integrated reversing gear

Application

Application: tapping, roll forming

Machine type: machining centres and special purpose machines

Features

- self reversing gear

- direct collet location

- damping elements between drive key in the spindle and the coupling sleeve

- balls used in the couplings elements

- hydrostatic pressure compensation for IC version

- constant tapping speed (through built- in reversing gear)

- exchangeable drivers BN17…

- built-in length adjustment screw

- sealed, stable version of the stop arm

Advantages

- reversing of machine spindle not required – shortest processing time possible, minimum time saving 200 – 400 ms per thread, substantially less electrical power consumption

- high concentricity – better life time of the tool, reduced wear, less unbalanced mass

- avoiding premature wear – less maintenance intensive

- exact disengaging point – exact thread depth, high repeat accuracy

- no axial movement of the spindle into tension, even when the coolant flow is blocked – no risk of collision through extended tool

- ideal cutting conditions – longer tool life time

- positive torque transmission of the tap and of the driver in the spindle – no twisting or slipping of the tap in the collet

- taps can be set to the required length – no input data error of tool length in machine offset (no risk of collision)

- no malfunction due to contamination or through too much gap in the stop arm – reduced down time of the machine, prevention of collision / no damage from displaced stop arm