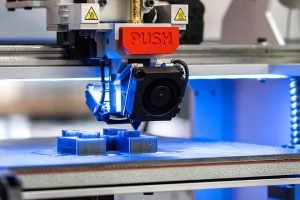

Printer 3D - 3DGENCE ONE

3DGence ONE gives you the freedom to materialize your projects and ideas.

It uses FDM technology and works with most of the filaments available on the market.

The printer has multiple patented solutions, like the quick hotend exchange PUSH system, autocalibration and autocompensation.

3DGence ONE’s unique construction guarantees a perfect printing stability and top printout quality.

3DGence ONE is ideal for prototyping, low volume manufacturing, producing molds and models.

Exchangeable hotends

3DGence ONE is equipped with a patented hotend, together with its quick replacement “PUSH” module.

It allows for a quick hotend exchange, making it really easy to swap a printing filament or to change a nozzle.

Autocalibration

3DGence ONE examines its heatbed in 500 different spots using the nozzle tip.

This process called autocalibration detects any possible surface irregularities.

Then, it uses the gathered data to perform an autocompensation, which guarantees the same nozzle-to-table distance, at all points of the print.

Ceramic heatbed

Ceramic heatbed used in 3DGence ONE, makes printouts stick to it without the need for additional solution.

The printouts are easy to remove and their bottom surface has a natural-looking texture.

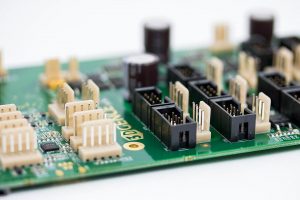

Dedicated electronics

3DGence Titanium has 2 levels of thermal protection of the hotend and 3 levels of thermal protection of the heatbed.

Electronics is additionally equipped with circuit and overload protection.

Download the brochure