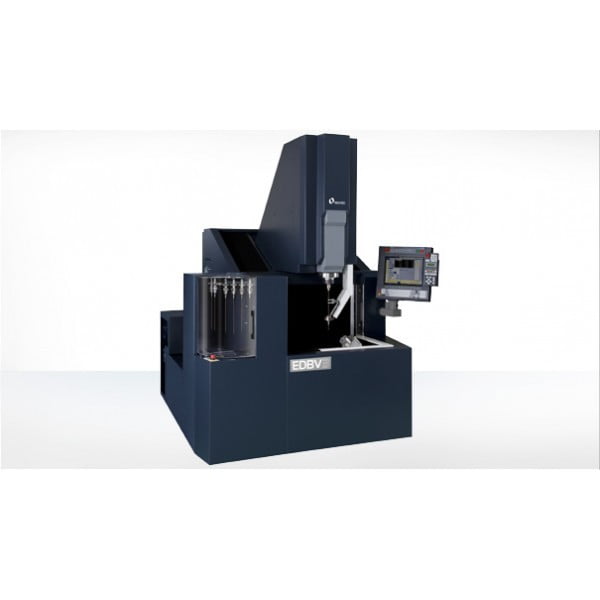

Sinker Makino EDBV3 EDM

EDBV3 EDM Hole Drilling

The newly developed water-based EDBV3 (Electrical Discharge Blades and Vanes) machine has been specifically designed for blade and vane machining in the aerospace and power generation industries. The machine has been purpose built to deliver top performance and optimal speed while preventing internal work piece back striking in the drilling of cooling holes and diffusor shapes.

Ideal for unattended productivity in EDM hole drilling, the machine features a unique tooling system that integrates both automatic tool change and guide changing into one common assembly that can be quickly exchanged within 30 seconds. The EDBV3 has also been configured with an integrated 2-axis rotary table for angular features in blade and vane machining. Additional features added for high efficiency EDM hole drilling include pre-programmed cycles for diffuser shapes, intelligent electrode length management, and internal water quality and temperature control systems.

The EDBV3 utilizes a 1000 rpm rotating spindle with high pressure flushing during blade and vane machining, and can produce holes down to 0.008 (0.200mm) in diameter. To aid in the reliable performance of small diameter EDM hole drilling, the machine includes an automatic middle guide arm that supports the pipe electrode during operation and prevents the whipping or bending of the electrode.

By offering higher productivity and improved reliability, the EDBV3 delivers the features and capabilities that really matter in EDM hole drilling for blade and vane machining.

Makino is dedicated to providing the most advanced machines and technology to meet and exceed industry requirements. Makino’s EDM Hole Drilling machines are feature packed, are well suited for production, and deliver high performance levels that matter to your operations. Several EDM Hole Drilling models are available, and range in capability to support any application.

EDM Hole Drilling machines that are dedicated to high volume production are offered, as well as a versatile machine platform that can perform both EDM Hole Drilling and standard RAM EDM operations. All of Makino’s EDM Hole Drilling machines feature a programmable W-Axis arm unit that supports and positions the electrode die guide for improved part accuracy. Additional design elements that impact EDM Hole Drilling include ATC (Automatic Tool Change) and AGC (Automatic Guide Change) capability, and a Middle Guide system that supports the electrode tube during small diameter hole machining. These features greatly extend unattended machine operations and increase productivity.

Common machine uses are for precision EDM Hole Drilling of diameters below 0.010” (0.250mm) diameter while being able to repeatedly size and produce accurate features. Typical machine uses include the Aerospace and Power Generation industry, to the Medical and Electronics manufacturing, and Micro Machining applications.