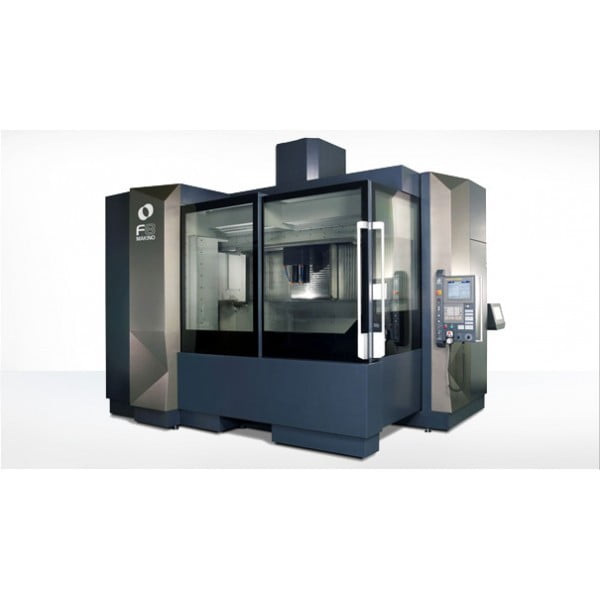

Wire EDM Makino U32J

Makino U32j – Wire EDM

Makino’s Uj-Series of WEDM machines, the U32j and the U53j, take accuracy and finish capabilities to a higher level. Targeted to applications in precision plastic injection molds, engineered plastics, precision stamping tooling, and medical and micro-manufacturing, these machines are capable of producing geometric accuracies of ±0.00008 inches to 0.00012inches, and surface finishes down to 0.8μmRy in tool steel and 0.5μmRy in carbide. Static axis accuracies of 3μm for straightness and 4μm for squareness and parallelism are delivered from the factory.

These figures are achievable due to the mechanical accuracy and technology advancements built into each machine. The stacked cube design of the Uj-Series eliminates any possibility of overhang of any cast units when the axes are run to their full travel limits. This helps maintain straight, precise movement while eliminating droop as the axes move through their full travel. X- and Y-axis ballscrews are 32mm, anchored at both ends, and laser aligned to high-precision linear motion guides. As a testament to how well Makino WEDMs are built, we offer a limited 10-year, or 20,000-hour, ballscrew warranty on these machines.

Using an improved automatic wire threading system, the Uj-Series machines will perform AWT of 10 seconds in high-speed mode, and 15 seconds in fine-hole mode. Uj-Series machines come standard with Makino’s Split precision V guides, which are covered by a 12,000-hour warranty. Also available are PICO precision wire guides, recommended for auto threading holes smaller than 0.025 inches in diameter and/or with hole centers closer than 0.060 inches. PICO precision wire guides are also recommended for machining complex, variable land details in precision stamping work.

An advanced wire drive system, coupled with the mechanical accuracy of the machine and BellyWIZARD™ technology, allow the Uj machines to produce straighter parts faster, while using up to 50 percent less wire than other machines in the class.

The Uj-Series machines come standard with a three-sided drop tank, fully accessible from all three sides. With a full-color, 15-inch touch-screen monitor and fully functional remote handbox with digital readout, the Uj-Series machines are designed to be user-friendly and easy to set up and operate.

Wire Electric Discharge Machine

Numbers matter. That’s why, with more than 140 patents, Makino is the world leader in EDM technology, providing faster processing times and superior surface finishes for even the most complex and involved part geometries.

By combining innovative Makino machine tools and software with game-changing support from Makino Engineering Services, shops of every size are competing and winning the kind of work that matters on the global EDM stage. The flexibility of Makino technology and proven turnkey engineering solutions allows for EDM solutions at all levels to help further reduce operational costs.

BellyWIZARD™ is an exclusive Makino wire EDM technology that automatically selects the optimum machining parameters for those applications that, top to bottom, require exceptionally straight parts. BellyWIZARD meets today’s manufacturing demands for lower costs, reduced lead-times and tighter tolerance by providing up to 40 percent improvement in part straightness with fewer passes than conventional wire EDM technology.

Additional Information:

Reduce Belly/Bow

One of the most difficult challenges faced by wire EDM operators is the machining of vertically straight workpieces to very close tolerances. Inaccuracies are usually at their worst in the center of the vertical span of a workpiece. These inaccuracies are typically defined as a “belly” or “bow” in the workpiece. Such an error occurs 90 percent of the time during the initial rough-cut operation.

The advantage of using BellyWIZARD wire EDM technology is that it reduces the belly or bow in workpieces during these roughing operations. By reducing the belly or bow in the rough cut, thus cutting closer to the final net shape, this technology reduces or eliminates the need for additional skim-pass machining.

When skim-pass machining is necessary to achieve finer surface finishes, BellyWIZARD helps to reduce the total cycle time and consumable costs by reducing the amount of error (belly/bow) and remaining material on the final part, thus leading to faster skimming times.

Improved Compensation

BellyWIZARD technology is built into the E-code, so that parameters change automatically with workpiece height. The technology compensates for changes in the wire caused by eroded wear and wire lag. This compensation is done by automatically machining on a slight taper in the rough cut and through adaptive servo movements. The result is that BellyWIZARD produces straighter and more accurate parts without increased wire consumption. The improvement in part straightness can be as much as 40 percent over conventional wire EDM technology. This reduction in both total cycle time and production costs makes your shop more profitable.

H.E.A.T. (High-Energy Applied Technology) is a Makino advancement in wire EDM technology that dramatically reduces cutting times while maintaining exceptional part straightness with one- or two-pass cutting accuracy.

• H.E.A.T. cuts parts 18 to 44 percent faster than conventional wire EDM approaches while holding tolerances of straightness to 0.0005″ (T.I.R.) with one pass and 0.0002″ (T.I.R.) with two passes.

• H.E.A.T. increases skim speeds by 50 to 100 percent in real-world applications and conditions including poor flushing situations, non-sealed nozzle applications, parts with uneven surface thickness and through holes as well as parts up to 6 inches tall.

• H.E.A.T. delivers high-speed performance in difficult, real-world EDM production environments, especially job shops specializing in medical, aerospace and similarly demanding parts.

New H.E.A.T. addresses all types of available wires for cutting tool steels:

• Brass and coated wires

• Paraffin and non-paraffin wires

• High zinc

H.E.A.T. generator enhancements:

• BellyWIZARD™ – Unmatched part straightness

• CornerWIZARD™ – Excellent geometry control

• PowerWIZARD™ – Superior wire-break prevention/optimized machining speed and flushing control

SurfaceWIZARD™ is an important innovation from Makino that improves performance in difficult, real-world production of EDM parts for medical, aerospace and other applications where precision and exceptional surface quality is required. SurfaceWIZARD is particularly useful in parts with variable shape, thickness or sudden changes in thickness, such as a stepped part. It also produces excellent results cutting through cross-drilled holes or other similar detail.

Before SurfaceWIZARD, burning parts of this kind would often leave “witness” lines, the telltale lines left at the transition from one-step thickness to the next. To remove witness lines, a part would require either bench work or secondary operations, each of which increases production costs and slows delivery. SurfaceWIZARD technology virtually eliminates witness lines and maintains part straightness.

Benefits of SurfaceWIZARD:

• Minimizes witness lines that occur due to material thickness and stepped changes

• Eliminates wire-break issues

• Improves part straightness

• Achieves more consistent, higher-quality surface finish

• Suppresses errors caused by changes in machining condition variables by employing new generator and adaptive control technologies