BevelCut Plasma Cutting Machine

General Specifications

High Mechanical Accuracy…

BevelCut is an upgraded version of ProCut. It is offering angle cutting by ±45° with a perfect finish and hole for bolt. BevelCut allows alternative results such as Y, X, V, K welding preparations.

High Performance…

High quality provides higher performance. BevelCut increases your capability of production with HyDefiniton power source. BevelCut enables the customers to convert traditional plasma cutting to more complicated cutting solutions.

Standart Equipment

♦ 5 Axis Automatic Cutting HeadHypertherm Edge Connect CNC

♦ Hypertherm Edge Connect CNC

♦ Hypertherm Plasma Power Source

♦ 19,5” Touch Screen

♦ Hypertherm Pronest Nesting software

♦ True Bevel Technology

♦ True Hole Technology

♦ Torch Collision Protection System

♦ Automatic Torch Height Controle

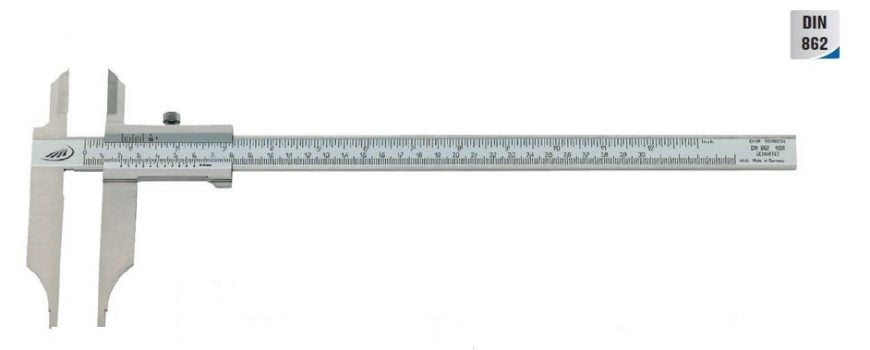

♦ Axis positioning accuracy ± 0,02 mm

♦ Axis positioning seed max. 20 m/min.

♦ Remote assistance

♦ Laser pointer for plate alignment

♦ Automatic dust and fume extraction system

♦ Pause / resume last part (Eg. electricty cut)

Optional Equipment

♦ Plasma Power Sources

— HPRXD Series

> HPR400XD

> HPR800XD

— XPR Series

> XPR170 – choice of CORE / VWI / OPTIMIX Automatic Gas consoles

> XPR300 – choice of CORE / VWI / OPTIMIX Automatic Gas consoles

♦ Oxy Cutting System with capacitve sensor system

♦ Oxy Cutting System wtih Auto Gas Console

♦ Tube Cutting

♦ LoyalMak Jet Filter

♦ Lateral Drawers for slag collection system