Precision open flat macine - Lapmaster Wolters Model 20

The Lapmaster Model 20 is a bench-mounted unit with a heavy duty carbon steel weldment base.

The machine is of the “ring lapper” or “planetary-lapper” configuration, enabling high standards of flatness and surface finish to be routinely achieved.

The Model 20 is derived from the popular Model 12 and 15 machines but features a steel weldment base instead of castaluminum. A scaled-up lapping plate, conditioning rings and convenient “wrap-around” worktable combine to form a unique

package.

The Model 20 is the largest bench-mounted machine in the USA offered by any company.

In-process lap plate flatness control is provided for by three conditioning rings,which locate in yoke/roller bearing assemblies. Work pieces are located within carriers or appropriate fixtures which run within the rings.

Large parts of cylindrical shape can be substituted for the rings.

The Model 20 is ideally suited for lapping low or high production quantities. In-shop lapping reduces costs of component processing and equipment maintenance programs. Worn parts are reconditioned and salvaged, thus eliminating scrap.

Valve bodies, discs, gears, vanes, valve plates and shaft seals are a few of the components benefiting from the lapping process.

The Model 20 is equally at home in the laboratory, where it can be used to process a wide variety of materials including semiconductors, electro-optics, ceramics and others. These results can then be applied to a production situation.

STANDARD FEATURES

• Heavy duty steel weldment base.

• W rap-around worktable facilitates parts handling.

• Three conditioning rings with roller yoke and bearing assemblies to facilitate in-process plate flatness control.

• Abrasive feed system designed for water or oil based lapping slurries, consisting of a 1/15hp/0.05 kW pump, tank and

three outlet system with individual variable flow control. This permits uniform lapping rates at each work station.

• High torque drive unit consisting of 1hp/0.75 kW motor and heavy duty, sealed maintenance – free gear reducer. Lap plate speed 70 rpm.

• Electrical system wired for 110 volts, 60 hertz, 1 phase. Automatic digital cycle timer: time ranges from 0.1 to 999 seconds,

minutes or hours.

• Removable waste container.

OPTIONAL FEATURES

• Electronic variable speed drive (0-70 RPM).

• Diamond slurry dispensing systems.

• Various lapping/polishing plates.

• Non – standard voltages.

• Custom machines and tooling.

STANDARD SPECIFICATIONS

• High density , cast iron radially serrated lap plate 20” O.D.x 5” I.D./508mm O.D.x 127mm I.D.

• Three high density, cast iron serrated conditioning rings 9” O.D.x 71/2” I.D./ 229mm O.D.x 191mm I.D.

• Three high density, cast iron pressure plates with lifting eye-bolts 77/16” dia.x 11/2” thick/ 189mm dia.x 38mm thick.

• 20”/508mm hardened straight edge.

• Lap plate lifting tool. Standard Tooling.

• Three micarta workholder discs 77/16” dia.x 1/8” thick/ 189mm dia.x 3.2mm thick.

• Three sponge rubber pads 77/16” dia.x 1/2” thick/ 189mm dia.x 13mm thick.

• Starter sample of Lapmaster abrasive.

• Star ter sample of Lapmaster vehicle.

• Operation and Maintenance Manual.

• Allen wrench.

APPROXIMATE WEIGHT• 435 lbs/ 196 kg

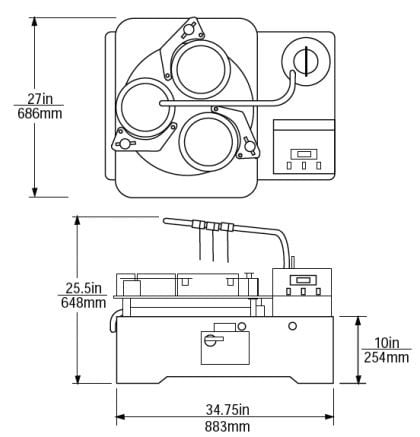

APPROXIMATE DIMENSIONS • 34.75” x 27” x 25.5”/ 883 mm x 686mm x 648mm