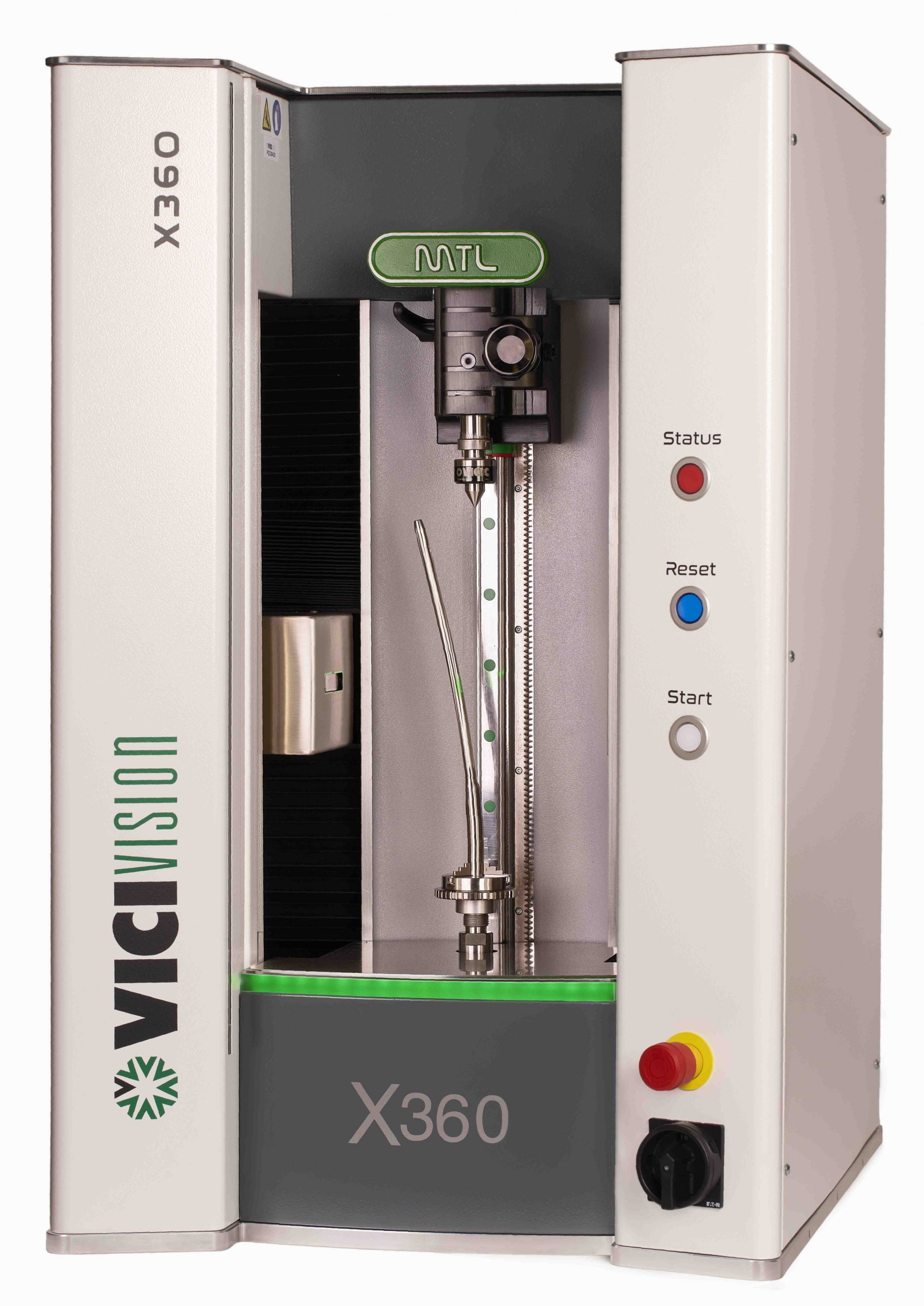

Optical measuring machine VICIVISION MTL X5, X10, X360

Optical measuring machine VICIVISION MTL X5, X10, X360

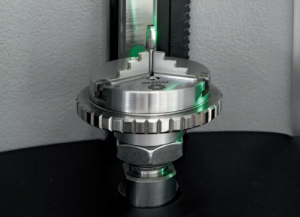

MTL X5, MTL X10 and MTL X360 are optical measuring devices specifically designed to measure micro-mechanical parts, dental implants, watch parts and micro-parts in general.

These high resolution machines detect even the smallest details. Measuring instruments designed for every need:

- Coaxiality,

- Cylindricity,

- Axial and radial run-out,

- Roundness,

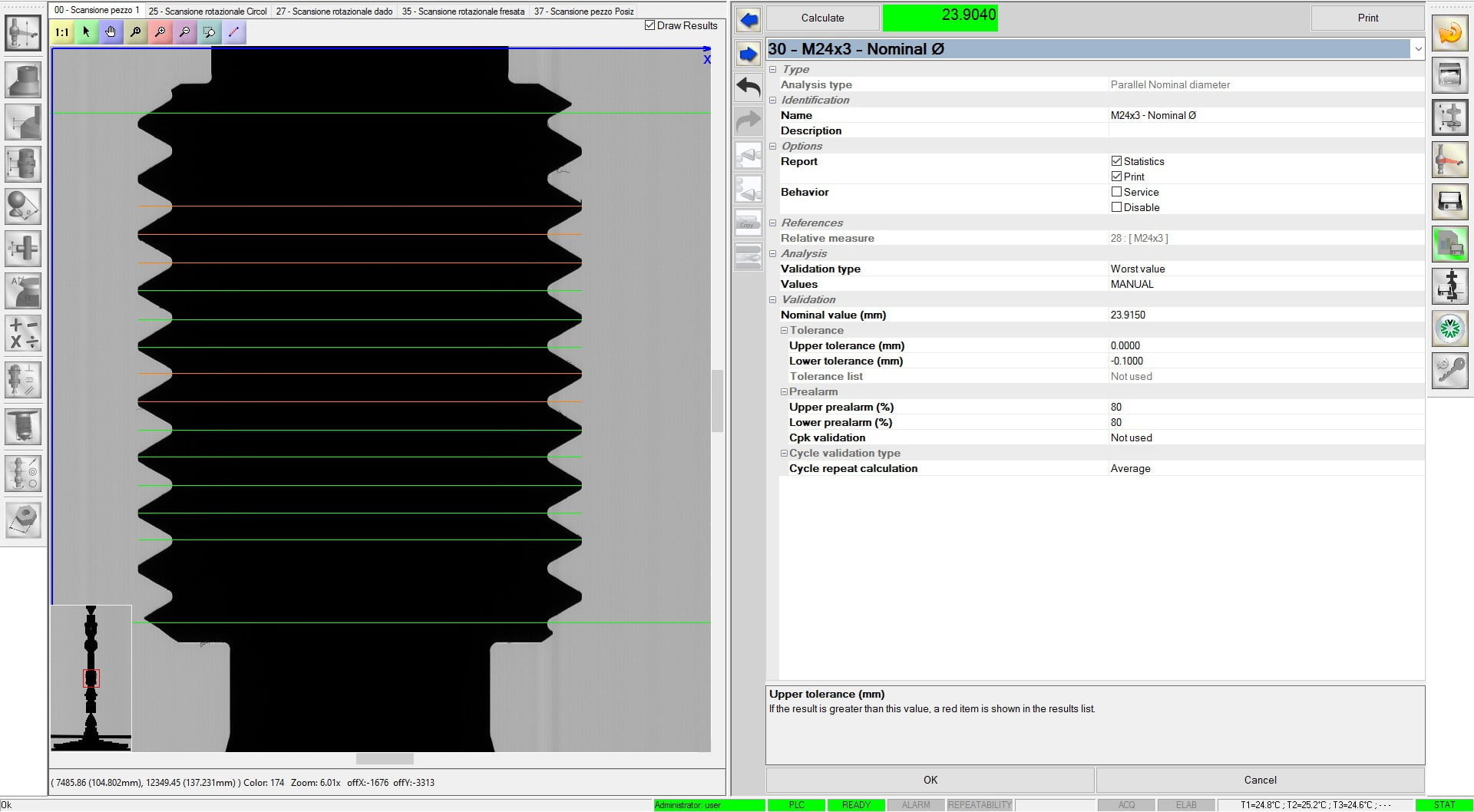

- Thread measurements,

- Nut measurements.

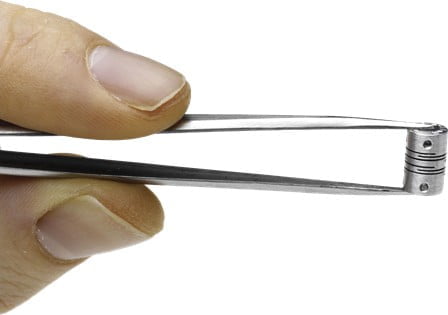

Designed for small components

The design facilitates loading and unloading operations, even with difficult to handle parts. No openings or undercuts in the machine eliminates the risk of small parts falling.

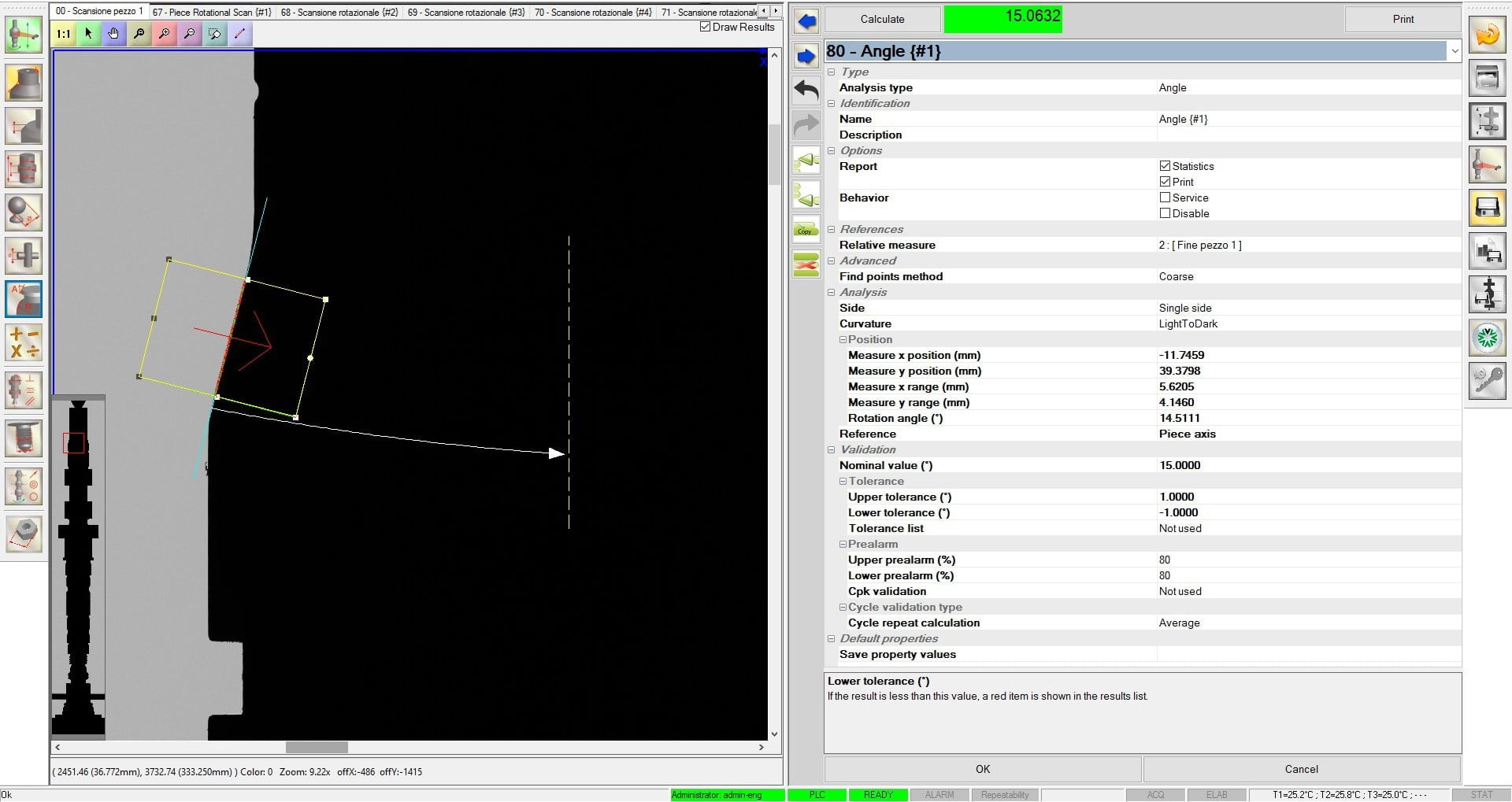

Data collection

All the data are collected by the system for statistics and traceability purposes to produce measurement reports and to monitor the production trend, meeting the needs of Industry 4.0.

For specific applications

MTL X stands out for its extreme efficiency in measuring complex elements such as straight and conical systems, abutments, expanders, caps, cover screws, ball

attachments and titanium pivots.

Download the brochure