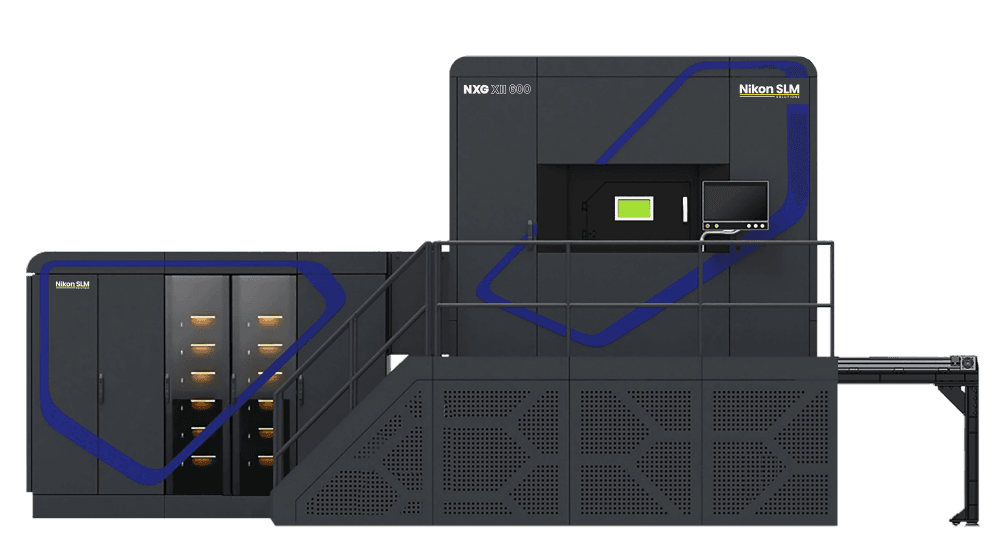

Nikon SLM Solutions - SLM® NXG XII 600

The NXG Series stands as a testament to the revolutionary spirit of Nikon SLM Solutions, redefining what’s possible in additive manufacturing. This series is not just a leap forward; it’s a quantum leap in the AM landscape, offering unmatched speed, precision, and scalability. The NXG Series is a masterpiece of engineering, a radical departure from conventional AM systems, designed for those who dare to innovate beyond boundaries. With its cutting-edge technology, the NXG Series embodies the future of production, delivering unparalleled efficiency and quality. Experience the revolution unleashed with the NXG Series—a machine like no other, where every build is a testament to the power of innovation.

Rapid Production Speed

The NXG series outpaces standard systems with 20x faster speeds and introduces a unique removable build cylinder to slash idle times, sharply reducing part costs and total ownership expenses.

High-Powered Lasers

With 12 lasers, each generating 1000 Watts of power, the NXG ensures rapid and precise melting of metal powder, facilitating high-quality and consistent part production.

Optimized for Large Components

Tailored for printing large parts, the NXG offers an expansive build volume and rapid deposition, streamlining the manufacturing process for oversized components.

Precision Zoom Functionality

Featuring a unique zoom function, the NXG provides enhanced control over printing parameters, enabling precise adjustments to accommodate diverse part geometries and optimize build quality.

Efficient Large Layer Deposition

The NXG’s capability for large layer thickness allows for efficient material deposition, making it ideal for printing intricate features and delicate patterns with exceptional precision and surface finish.

Enhanced Scalability

With its ability to rapidly produce large parts, the NXG offers enhanced scalability for manufacturers, enabling them to meet growing demands and expand production capacity with ease.

Improved Manufacturing Flexibility

The NXG’s versatility in printing large parts with fine features and delicate patterns enhances manufacturing flexibility, allowing for the creation of complex components without compromising quality or speed.

Cost-Effective Production

By significantly reducing production time and maximizing efficiency, the NXG offers a cost-effective solution for manufacturers, minimizing operational expenses and optimizing return on investment.

Quality Assurance

With its precision zoom functionality and large layer deposition capability, the NXG ensures consistent and high-quality part production, minimizing defects and rework, and maintaining stringent quality standards.

Innovative Technology Leadership

As a flagship additive manufacturing system, the NXG represents the pinnacle of technological advancement, positioning manufacturers at the forefront of innovation and competitiveness in their respective industries.