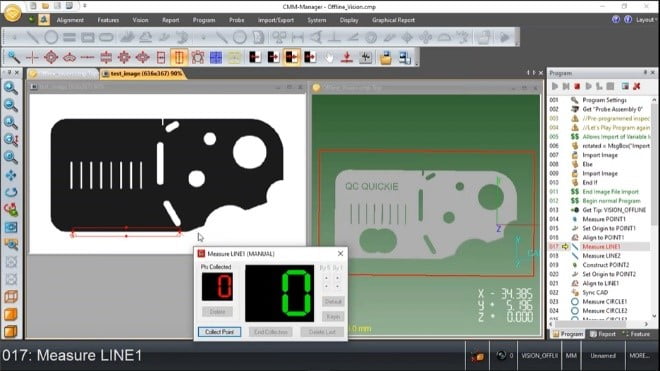

Nikon CMM - Manager

CMM-Manager from Nikon Metrology is a multi-sensor inspection software that runs on almost all CNC, manual and portable CMMs. Recently, CMM-Manager has also been adapted to support Nikon Metrology’s multisensor video systems such as VMA and VMZ-R. Unlike traditional digital display technology, the CMM-Manager offered by Nikon Metrology has a much more user-friendly interface that makes the software easier to use. Because the software supports a variety of CMMs, including handheld microscopes and multi-sensor video systems, it is also useful for merging multiple systems into a single software, streamlining inspection operations.

Features and benefits

Full alignment options

- Advanced alignment options for any part, regardless of complexity or geometry

- Ability to align using touch probe, video focus or laser focus

- CAD import – 2D DXF / IGES – 3D IGES / STEP.

Efficient measurements

- Possibility to perform combined measurements (touch / video)

Complex reporting

Print, save or output reports to external systems such as SPC software.

- Excel, PDF, Text, HTML, CSV

- 3D colour graphic reports

- GD&T – ASME Y14.5 2009.

Download the brochure